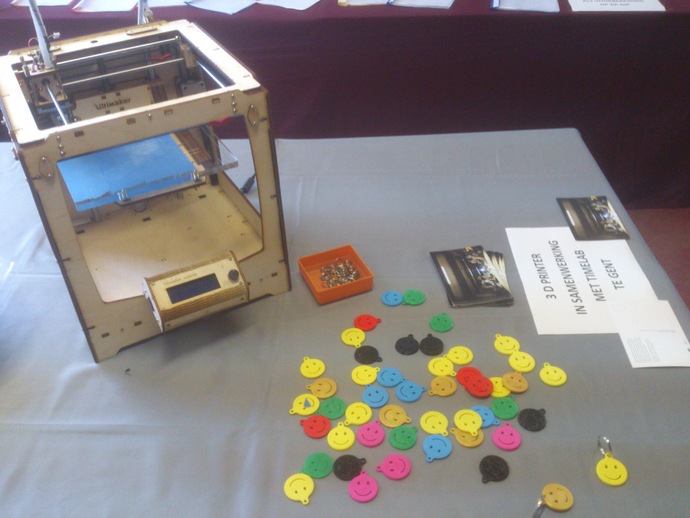

Smile Key ring as printed @ PHTI Hamme

thingiverse

Smile Key ring printed on the open school day @ PHTI Hamme. As they where milling in alu on the 1st floor, we where printing a simular key ring on the 2nd floor ;-) This was to show the people that the product could also be made without chips or any other leftover. The print was build with 45% infill meaning using less material to build a product. smile4_5.stl is to produce 5 in a row. Enjoy, Xiao Shi Zi. Instructions Printed on the Ultimaker with following settings: [profile] filament_diameter = 2.89 nozzle_size = 0.4 wall_thickness = 0.6 retraction_enable = True layer_height = 0.2 solid_layer_thickness = 0.6 fill_density = 40 print_speed = 50 print_temperature = 230 support = None enable_raft = False filament_density = 1.00 skirt_line_count = 1 skirt_gap = 2.0 retraction_min_travel = 5.0 retraction_speed = 40.0 retraction_amount = 4.5 retraction_extra = 0.0 travel_speed = 150 max_z_speed = 3.0 bottom_layer_speed = 20 cool_min_layer_time = 5 fan_enabled = True bottom_thickness = 0.2 object_sink = 0.0 enable_skin = False plugin_config = model_matrix = 0.707106781187,0.707106781187,0.0,-4.32978028118e-17,4.32978028118e-17,1.0,0.707106781187,-0.707106781187,6.12323399574e-17 extra_base_wall_thickness = 0.0 cool_min_feedrate = 10 fan_layer = 1 fan_speed = 100 fan_speed_max = 100 raft_margin = 5 raft_base_material_amount = 100 raft_interface_material_amount = 100 support_rate = 80 support_distance = 0.5 infill_type = Grid Hexagonal solid_top = True fill_overlap = 25 bridge_speed = 100 sequence = Loops > Perimeter > Infill force_first_layer_sequence = True joris = False retract_on_jumps_only = True hop_on_move = False [alterations] start.gcode = ;Sliced {filename} at: {day} {date} {time} ;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density} ;Print time: {print_time} ;Filament used: {filament_amount}m {filament_weight}g ;Filament cost: {filament_cost} G21 ;metric values G90 ;absolute positioning M107 ;start with the fan off G28 X0 Y0 ;move X/Y to min endstops G28 Z0 ;move Z to min endstops G1 Z15.0 F{max_z_speed} ;move the platform down 15mm G92 E0 ;zero the extruded length G1 F200 E3 ;extrude 3mm of feed stock G92 E0 ;zero the extruded length again G1 F{travel_speed} M117 Printing... end.gcode = ;End GCode M104 S0 ;extruder heater off M140 S0 ;heated bed heater off (if you have it) G91 ;relative positioning G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure G1 Z+10.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way G1 Y200 F{travel_speed} M84 ;steppers off G90 ;absolute positioning Enjoy, Xiao Shi Zi.

With this file you will be able to print Smile Key ring as printed @ PHTI Hamme with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Smile Key ring as printed @ PHTI Hamme.