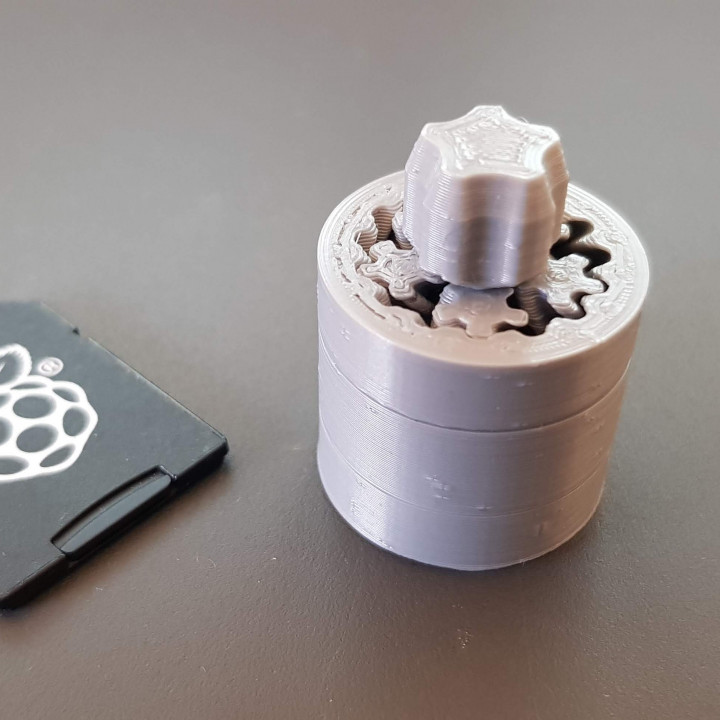

Solid Core Compound Planetary Gear Joint

myminifactory

The elbow joint from my robot arm model. Also on GitHub. Gear ratio 1:44. This gearbox is an example of a compound planetary system where multiple planetary gear layers are stacked vertically. With the same number of evenly spaced planets in each layer both the central sun gears and planet gears are synchronised allowing them to be fused. I have not encountered another example of this arrangement and believe it to be of my own invention. The idea of adding or subtracting teeth from the ring gear emulating cycloidal drive is not new and harks back to WWII radar gear, however this prevents meshing with a sun gear (unless the number of teeth dropped is a multiple of number of planets). Furthermore synchronisation requires the sun gear teeth be some fixed multiple of the planet gears in each layer, this also requires bending the rule to avoid identical gear ratios in each layer. More conventional designs obeying R=S+2P are forced to separate sun gears, leaving idlers or omit them entirely in place of carriers or unsupported planet gears. Concentrating drive stresses and limiting torque due to shear and twisting forces. This design distributes the drive force along the entire length and elliminates the need for a carrier. The tradeoff is a slightly distorted involute gear profile as we stretch or compress teeth to mesh but well within the tolerances of FDM but even ideal involute gears suffer from sliding friction away from the pitch point.

With this file you will be able to print Solid Core Compound Planetary Gear Joint with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Solid Core Compound Planetary Gear Joint.