Solving for skeinforge flow rate

thingiverse

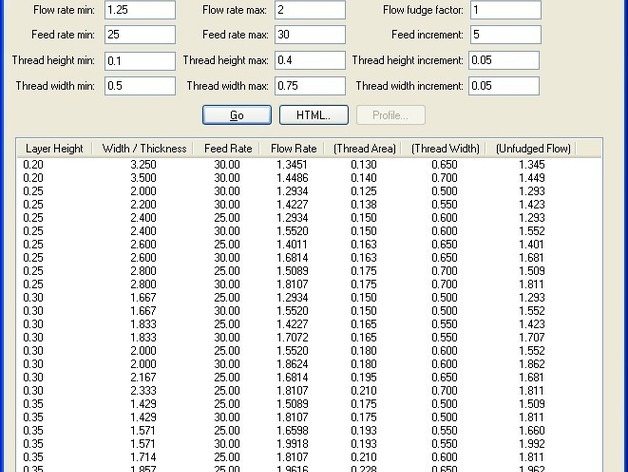

This program calculates optimal flow rates for 3D printing using various parameters. It's a work in progress and currently only compatible with Windows due to being coded in C#. The user inputs a range of values for different parameters, and the program iterates through them, calculating the best flow rate. The results can be saved as new skeinforge profiles, making it easier to find optimal settings for specific printing jobs. The user can also clone existing profiles and add generated values. The program is designed for Ultimaker machines, with recommended settings provided. Note that this tool is still in development and may change or improve in future versions.

With this file you will be able to print Solving for skeinforge flow rate with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Solving for skeinforge flow rate.