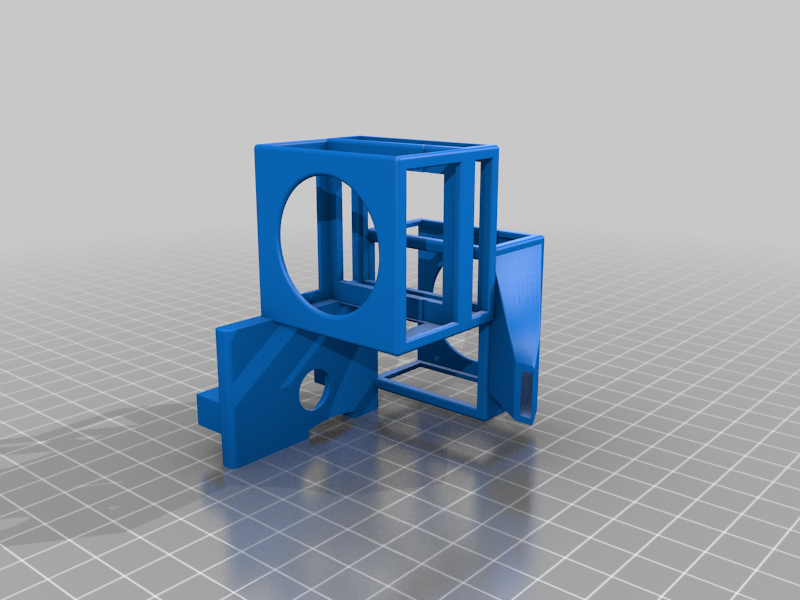

Spider Head and Mini Sherpa extruder supports

thingiverse

I have with those 2 files my final (for now) version for my combo Creality Spider head and my Annex Mini-Sherpa extruder. ### Turbo fans support I designed the fan support starting from my previous version with the original Creality Ender3V2 extruder (https://www.thingiverse.com/thing:5417916), the light one. It's low weight profile for 2 40x20 turbo fans. The air flows are strong and well separated. I just added the support (4 little cubes on top) in order to be able to firmly lock the connection between the fans support and the extruder support. ### Mini-sherpa support I designed the support in order to be very strong. Indeed, the mini-sherpa with the LDO motor and the gearbox pushes and pulls very strong and there should be absolutely no movement tolerated in this piece. I wanted also to give a very easy access for maintenance. That's why I did the rotation around the left axis. I hope you enjoy these designs. Edit 2022-07-17 : I saw a lot of mistakes with that point. Just to help other people with the setup, I explain here the process to determine the DEFAULT_AXIS_STEPS_PER_UNIT param Here is the formula : steps_per_mm = (motor steps per rotation * driver microstep number) * (plate number of teeth / axis number of theeth) / (effective axis diameter * pi) So on my Ender3V2 - the driver microsteps is 16. - the LDO motor is 1.8° pet step +-5% so it's 360/1.8=200 steps per rotation - the plate teeth is 50 - the axis teeth is 10 - the out diameter of the motor axis is 6mm I have got : steps_per_mm = (200 * 16) * (50/10) : (6*3.14159265) = 848.83 Then because the extruder's teeth enter a little bit in the material, it changes a little bit the diameter of the axis. So we adjust with a real test. Preheat extruder Mesure & mark 50 mm (or more, more is more precision) of filament above the extruder's entrance then ask the extruder to move 50 mm mesure what length of filament has really been extruded do the calculation : Steps_per_mm = steps_per_mm_previous_calculation * target length / real length For exemple I ask 50 mm and I get 50.5 then Steps_per_mm = 848.83 * 50 / 50.5 = 840.43 See my article : https://gratuitcestlbonprix.capital/grave/en/articles/

With this file you will be able to print Spider Head and Mini Sherpa extruder supports with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Spider Head and Mini Sherpa extruder supports.