Stepper Wheel - FireLine pulley 25% and 75% more torque than GT2 Belts

thingiverse

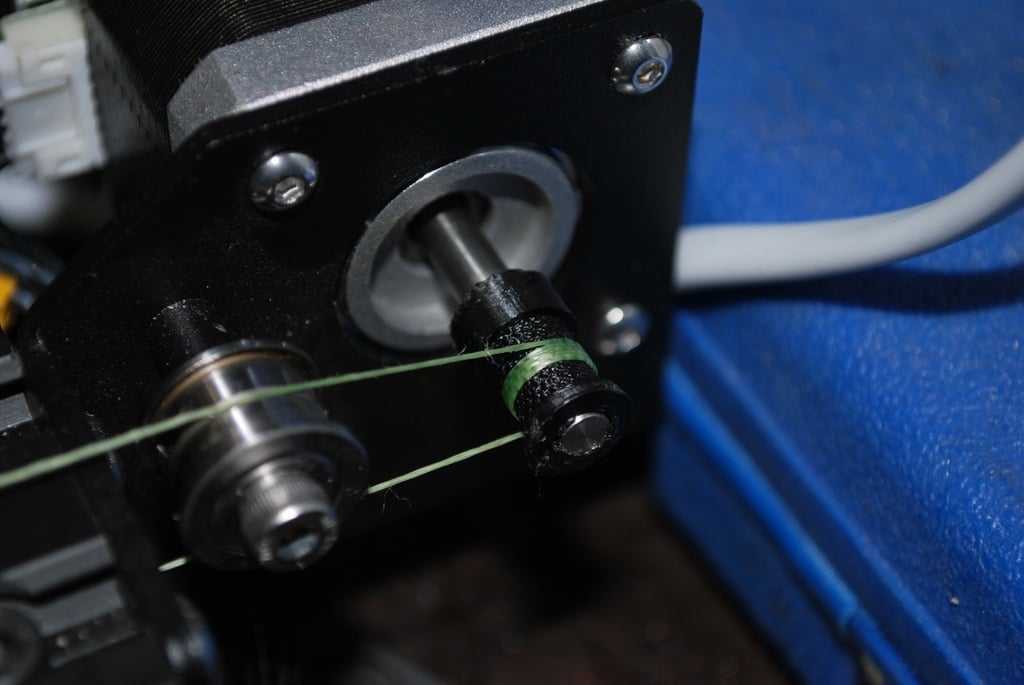

I have a **need for speed** and have been wanting to find a compromise between speed and cost, to be honest next step up from GT2 belts would traditionally be industrial grade ball-screw or pinion drive which both come with big caveats. Inspired by [Dualwire-Gantry (DW-G)](http://reprap.org/wiki/Dualwire-Gantry_(DW-G)) and the approach of using FireLine, this is a extremely strong fishing line with nearly no stretch, **the creators of FireLine claim there is no stretch however that's not entirely true**, however there is very little stretch compared to belts. I have designed two pulleys 10mm and 7,2mm, 7,2 gives you 75% more potential torque compared to a standard 12,6mm GT2 gear and 25% more torque from the 10mm pulley compared to the GT2 gear. I suggest using 10mm pulley for X axis and 7,2mm for the Y axis on a Creality CR-10 as wire from X axis does require the extra height from the pulley to not rub agains the V-Slot on the side of the motor, I strongly suggest winding the wire around the pulleys 3-4 times and a whole lot of tension to avoid slippage, keep in mind that after you install this modification you need to ensure that you have sufficient tension, if you have tensioner modification already installed I suggest by printing a test cube and while it print you keep tensioning till you are satisfied, I keep wires as tight as violin strings (that means very tight ;)). * **100** steps per mm for 10mm version. * **142** steps per mm for the 7,2,, version. You will want to print these in a material more heat resistant than PLA at very least ABS, after vigorous torture testing, dimensional accuracy will degrade over time due to heat traveling though the motor axle to the pulleys. **Idler sleeve for CR-10 added as the two part idler will wear on the string over time.** On my Creality CR-10S while still keeping good quality of prints I am running the following configuration. * Max Federate X and Y **266** * Max Acceleration X and Y **12000** * Acceleration Print and Travel **1000** * Jerk X and Y **30** I am easily able to print decent quality parts at 120mm/s infill, 60mm/s outer wall and 90mm/s inner wall. And it is fast, *extremely fast*! I wanted to find a speed where i got peak speed and performance the above [Benchy](https://www.thingiverse.com/thing:763622) is printed at * 150% scale * two wall shells * 0,8mm top/bottom * 0,4 nozzle * 0,1 layer height * 45mm/s inner/outer walls and top/bottom * 100mm/s infill and travel * 15% infill (zig-zag) * Ironing (concentric) * **4 hours and 13 minutes!** **As always configuration of printer is individual, you have to experiment to find the settings that work best with your particular printer.** I use [0,32mm FireLine](http://berkley.ex-purefishing.com/catalogue/lines,40748/superlines,40749/fused-line,40750/fireline-flame-green,8435.html) And some high speed footage. [](http://www.youtube.com/watch?v=v_olNelovEY) [](http://www.youtube.com/watch?v=3Tudna5DvAM) [](http://www.youtube.com/watch?v=rU5HJ9t7HO0)

With this file you will be able to print Stepper Wheel - FireLine pulley 25% and 75% more torque than GT2 Belts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Stepper Wheel - FireLine pulley 25% and 75% more torque than GT2 Belts.