Sugru Hotend Insulation for Rep2

thingiverse

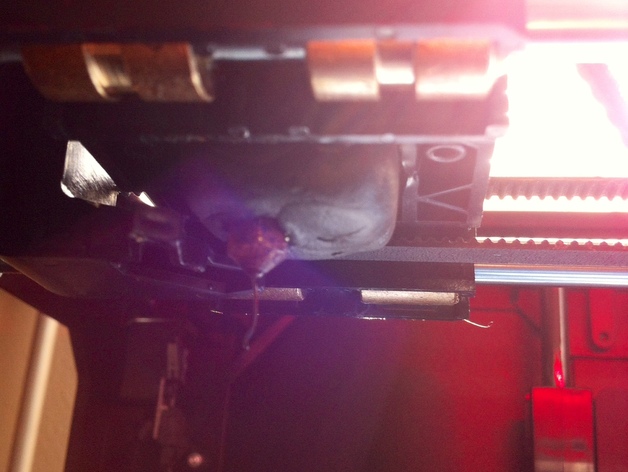

After a few failed prints (as is normal with this machine) you will probably notice that that hot filament will bork your existing insulation pretty quickly. It is some sore of cotton fiber wrapped in what appears to be kapton tape. This just wont do. For me I noticed that the cotton fibers absorbed a considerable amount of PLA over the hours. It was pretty nasty. So I came up with this solution to not only fix the problem but prevent it all together. Since this mod, I have noticed that my machine heats up noticeably faster and sees much less heat pollution beneath the build platform. The area directly beneath the nozzle sits about 15C cooler as confirmed by a laser thermometer whereas the surface of the insulation sits almost 35C cooler. There are no immediate visible changes in print quality, however this equation should, in theory, aid with bridging and increase the efficiency of your current filament fan. Thanks for reading! Instructions Sugru claims to be resistant to "+180C". This was enough for me to give it a try and it works quite well. I disassembled the extruder and pulled the existing insulation off of the heat block. I then cleaned the entire assembly ans applied a ~1.5mm layer of Sugru around being sure to leave room to swap out any parts such as the nozzle in the future. It is important to knead the Sugru extremely thoroughly before applying it to release any air bubbles. Air bubbles will expand and destroy your insulation. I let it cure for 36 hours to ensure that it was on for good. Finally, the extruder is reassembled and the build plate is re-leveled and you're off!

With this file you will be able to print Sugru Hotend Insulation for Rep2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Sugru Hotend Insulation for Rep2.