T8 backlash

thingiverse

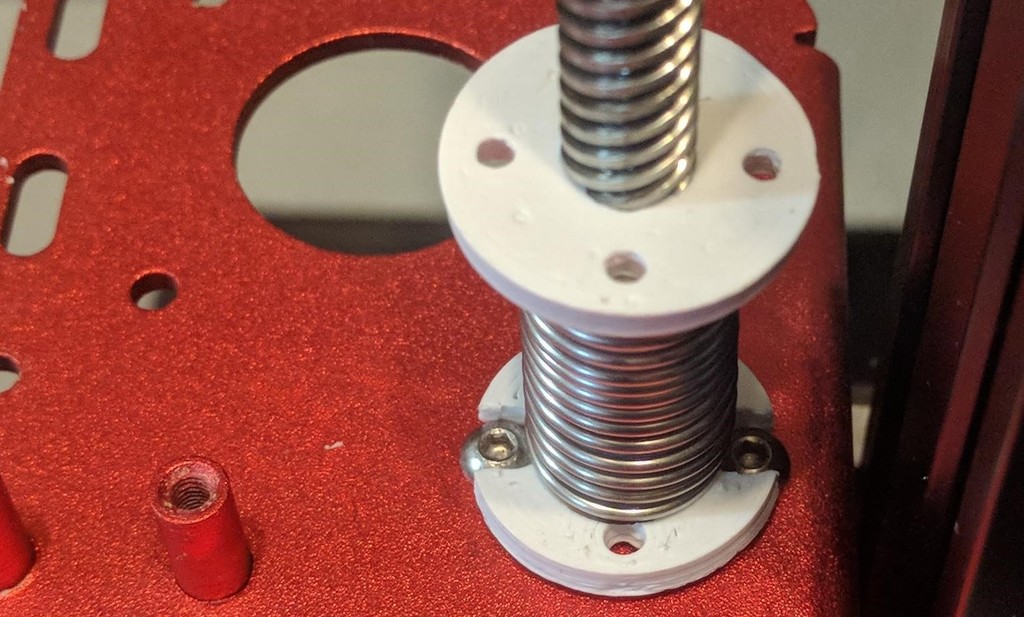

The Z axis was creating small layer thickness blemishes. This is a remix and mod of Backlash eliminating T8 Lead Screw https://www.thingiverse.com/thing:1808428 I printed 4 parts at 100% size in ABS for use in an elevated temperature chamber, excellent T8 fit. You need to mod the lower part of the set. 1. Drilled out the internal T8 threads 2. Drill the mounting holes larger to slip over the mounting bolt heads which stops the lower printed part from rotating (3rd pic) 3. Drill or countersink the mounting base to fit around the upper edge of the existing brass T8 nut if it sticks up like mine (2nd pic right most part) 4. I also snipped the holes in to slots but it is not required The spring is formed from 16 turns (not critical) of 0.045" SS welding wire. Coat hanger wire might also work. I make springs by tightly wrapping the wire around a rod or twist drill shank to establish internal diameter and then stretch the turns apart to the desired length. This wire yields and deforms or stretches at something over 6 pounds of force. The pictured spring produces about 2.5 pounds of downward force to firmly seat the original brass nut against the T8 lead screw in addition to the weight the X axis. Mounts from the top with the brass nut remaining bolted in place. Works great on my CRS10 pro.

With this file you will be able to print T8 backlash with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on T8 backlash .