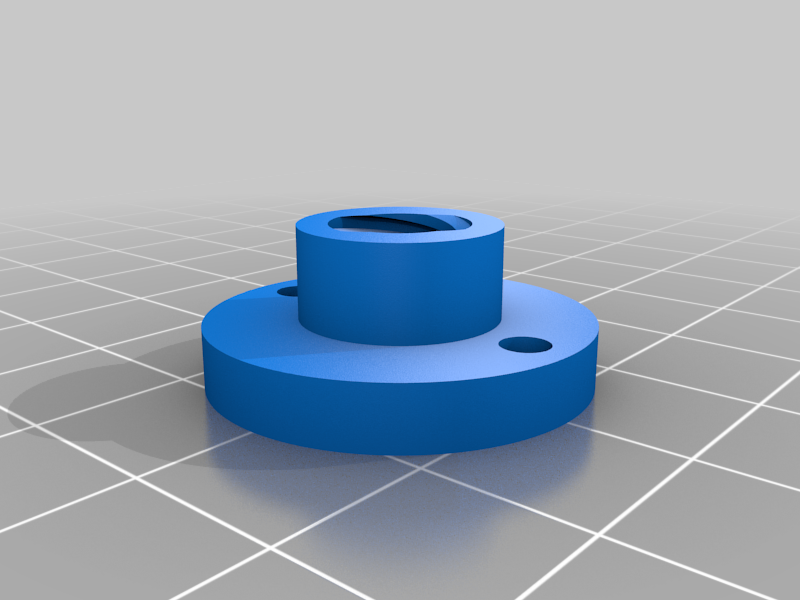

T8 Lead Screw Nuts

thingiverse

When trying different lead length screws on the Z axis of my MK3 Bear it was impossible to find POM nuts the right size for anything other than 8mm lead. So naturally, I made my own. I have found the nuts last 6-12 months on my three machines, but I recommend always printing a few extra pairs to avoid having to do the machine setup and material prep too frequently! I printed these in a nylon material - [Essentium PA](https://essentium3d.com/product/essentium-specialty-pa-nylon/) If you use something else that works out well, do let us know in the comments! Just keep in mind that the screws are not usually hardened and you want to make sure you are using a low friction material to avoid wearing the screws down. The nut should be the consumable half of the setup! Material Prep: Get it dry! I used a vacuum chamber for 12 hours with the PUMP ON. Stored with a liberal quantity of desiccant and fed to the printer in a [SpannerHands MK6](https://www.thingiverse.com/thing:2839275) Print settings I have had the best luck with: Bed Surface: Any with a happy helping of glue stick Bed Temp: 95c Nozzle Temp: 260c Nozzle: E3D Copper .25mm Extrusion Width: .26mm all around (small means sharper corners, thus a better fitting part) Perimeters: 5 Layer Height: .15 (My nylon seems to like the 60% of nozzle ratio) Infill: 20% Gyroid Skirt: None Brim 10mm (nylon likes to pull off the bed, big brims required) Cooling: None Speed: 15-25 mm/s Enclosure: Use it if you have it, it should help with material warping. F360 Source files: [T8, 2mm Pitch, 2mm Lead](https://a360.co/2J0gFDd) [T8, 2mm Pitch, 4mm Lead](https://a360.co/2TucnJ6) [T8, 2mm Pitch, 8mm Lead](https://a360.co/2TD425n) Make sure your extrusion settings are fine tuned! Internal dimensions are critical for a nice fit. The thread profile has a 0.025mm tolerance offset, which when printed on a tuned machine feels great on the screws. If the nut is feeling too constrained, either adjust and reprint or perhaps load up a leadscrew in your drill chuck and run the nut on and off a few times to see if it just needs to be cleaned up a bit. My first attempts at printing these were with a .4mm nozzle and they came out a bit tight. Using the drill to quickly break them in did the trick. My latest prints with .25mm nozzle did not need that extra clean up.

With this file you will be able to print T8 Lead Screw Nuts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on T8 Lead Screw Nuts.