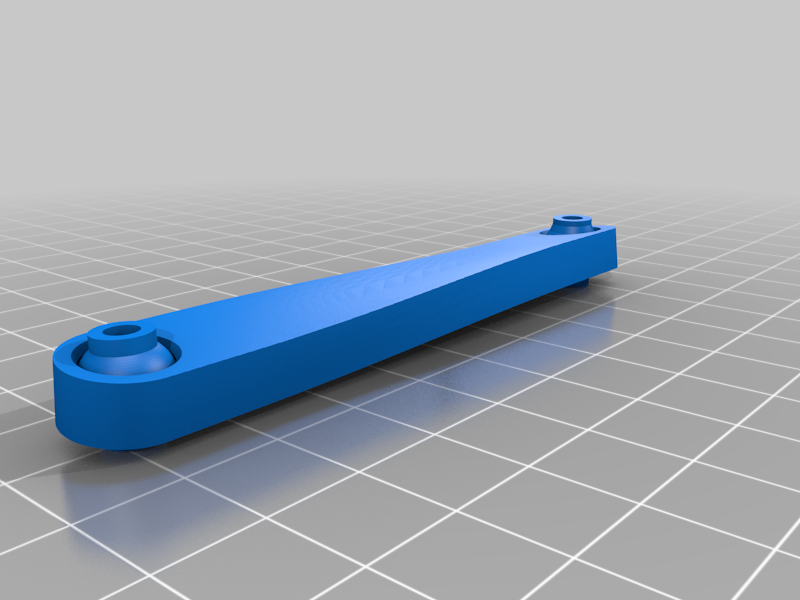

tarmo4 steering linkage tightened up

thingiverse

The original steering linkage appeared rather loose, and the ends were also rubbing against my 115mm tyres whenever the steering was locked to either side. Consequently, I reduced the space between the linkage and printed bearing, as well as rounding off the ends that came into contact with the tyre. A Fusion360 file has been attached for your reference. I utilized a 0.25mm offset from the original design, resulting in a total of 0.5mm less clearance around the bearing. However, please keep in mind that you may need to adjust this parameter based on your specific printer's requirements. Included are the Fusion User Parameters set to 0.25mm at present. You can simply modify this value and the model will automatically update the space accordingly. I strongly recommend calibrating the part before proceeding with a full print. Begin by cutting out just one end of the entire piece for a small test print. Then, insert a 3mm screwdriver through the screw hole to see if you can loosen the printed bearing. If it's easy to move, that's great! However, if it's too loose (you must be doing something right with your printer!), increase the offset by adjusting the linkage faces to move inwards towards the bearing. Conversely, if you're unable to budge the bearing, try decreasing the offset slightly – I noticed a significant difference between 0.2mm (which was too loose) and 0.3mm (where the printed bearing actually melted onto the linkage during printing). Ultimately, I settled on 0.25mm as the sweet spot. Once you've calibrated your part, make a copy of the STL file and mirror it in either the X or Y direction – it doesn't matter which. Then, print both sides simultaneously. Be gentle when freeing the bearings from their housing, as I found that excessive force can generate heat, causing them to stick together again.

With this file you will be able to print tarmo4 steering linkage tightened up with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on tarmo4 steering linkage tightened up.