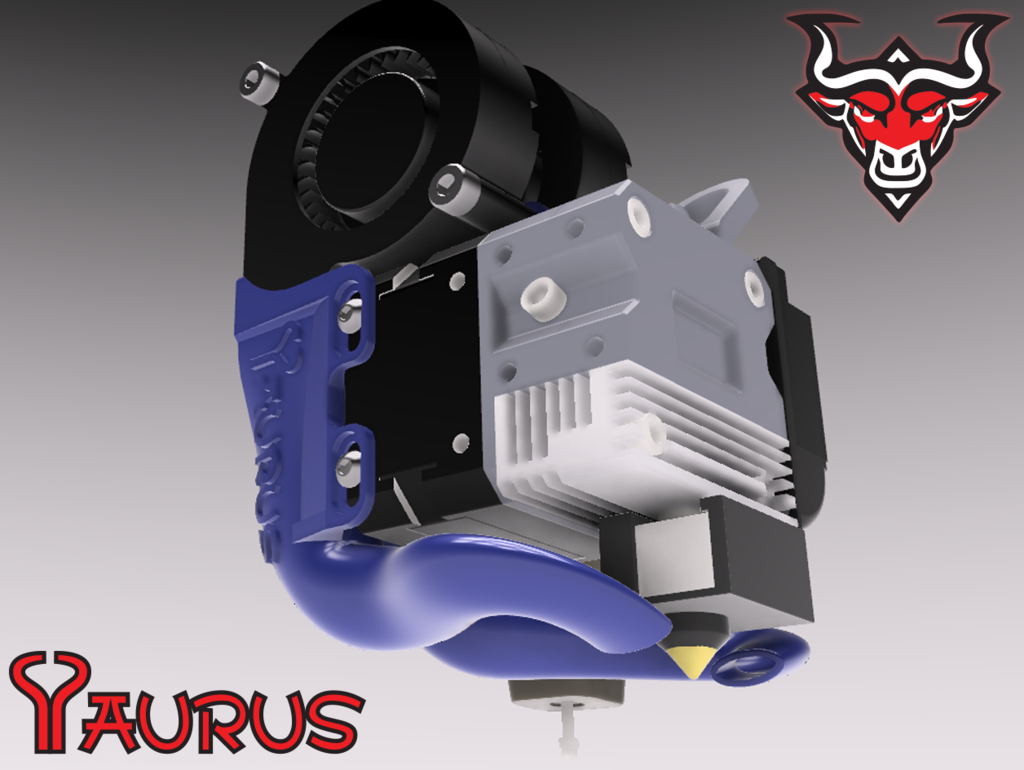

Taurus V4 Cooling Duct for Creality Sprite Extruder, Dual 5015 Fans, Ender 3 S1/S1 Pro/S1 Plus (Stock / Spider)

thingiverse

V5 Update This release has experienced a unexpected delay, due to some design features we wanted to do that the current design 3D environment wasn't able to handle (Fusion 360). While we convert everything to a new design software, V4 is still a very good option to try. The focus for V5 is mainly cosmetic/mechanical and internal design, you don't have to wait for that, please use V4 for now. This is a remix of the K3D duct design by Sorkin, which was already a great design at the time. I wanted to further optimize the airflow and fix a few things that others have complained about, and I struggled with myself. We are at version 4.0 now, because people around the entire globe/from many different countries started to contribute, tried this out and provided me with feedback that keeps making this thing perform better and better with every new release. Every single comment, idea and improvement request was evaluated and made it into this version in some shape or form. In a strange way, this is where organic design meets crowd·sourc·ing, resulting in a high performance duct design that has produced very consistent results and even set some new records in the 3D FDM printing world. We named this duct "Taurus" because when looking at it from the top, the shape looks similar to the horns of a Bull/Taurus, paired with massive air output. After several model iterations, the only things left from the original are the mounting ears and the fan supports, the rest is of my own design, with the help a lot of contributors (please see the credits). I'm not a computational fluid design engineer by trade (CFD), but learned a lot over the years. A good example is what water does, while flowing through pipes or down a mountain stream. As you turn the pressure up, dynamics change and it is no different than with air and cooling. Air molecules just have a lower mass, but the exact same dynamics apply - I think that every actual CFD engineer would agree with that. Computational fluid dynamics is still a very sketchy science and no matter how you simulate it and which algorithms are chosen for the simulation, it will bite you in the ass somewhere in terms of turbulence once a sharp turn is involved. My approach was to just do what made the most sense: Zero Turbulence, zero turns, no edges in the inner volume. This is the result of my quest to find the optimal path from the fans to the part to achieve the highest possible pressure at the cooling nozzle outlets. I actually got a lot of criticism about this approach, even from the original designer and thought many times that I might be on the wrong track, but the good results and positive feedback speak for themselves. If you're interested in CFD science and this is nothing new, here is why I did it in this way: The goal was to make the flow of air as "laminar" as possible, while at the same time increasing pressure by doing this: My approach was to keep a fluid/linear reduction in cross section on the inner volume, from the top, down to the business end of it, fully organic without any angular, sharp turns involved (causing turbulence and more back pressure as a result). The linear reduction in cross section causes the pressure to build up, turning the fan output into a high-speed jet of air, that we can now control and "shoot" directly at the center of the newly extruded filament bead. This provides high efficiency cooling at the optimal angle, while at the same time just undercutting the nozzle with the two precisely directed jets. Cooling the nozzle tip itself is obviously a bad thing to do and we want to avoid that. I have another theory on why this works so well. Have you ever wondered why golf balls have these dimples in them? Look it up, or click here: https://www.youtube.com/watch?v=fcjaxC-e8oY I believe the ripples from printing are creating this theoretical boundary layer, reducing friction and back pressure by accident, helping the laminar flow and allowing for improved transport of the air from the fan to the nozzle. Any type of turbulence by an edge in the inner volume would cause this effect to diminish. Another major design intent was the visibility of the extruder nozzle, which this design solves nicely. Heck, we might as well put a miniature camera to ride along on it now! :-) This mod is verified to be compatible with: - Ender 3 S1 - Ender 3 S1 Pro - Ender 3 S1 Plus As of version 4.0, this duct is compatible with: - Spider Hot End Mod (3.5mm lower, use the provided STL, not the stock one) This mod is NOT (yet) compatible with: - Volcano Hot End (I'm working on something with individual makers to make even that possible, although I have no way to test the volcano configuration) Update (06/24/2023): V4.01 Maintenance release (minor issue fixed) Update (06/21/2023): We just released V4 for both the spider and standard/stock hot ends. This release has a lot of changes in it, that originated from testing in multiple countries around the world and awesome feedback I got from various makers in the community. The old STL's have been removed and V4 is now officially released. You can learn more about what was changed in the update history section down below. Update (06/03/2023): The Spider version is almost complete (currently in testing) The Volcano version ist starting to emerge. Update (06/11/2023): The Spider version is ready for alpha trials. File name: Taurus-Sprite-Duct.V3.3-Spider-Alpha-IV.stl There will be more features coming for this design, as this is just the first working version. The routing of the duct tubes is specifically designed so that there is room for the new Beacon Eddy probe: https://beacon3d.com/ This version just doesn't have the mounting bosses yet, my probe hasn't arrived yet so I couldn't test if this would work. The PETG Benchy shown in the pictures was printed in 23 minutes without optimizing much, I just cranked up the speed on my printer to 330% (personal base Cura profile @ 100mm/s on a Sonic Pad) and the quality was amazing (no stringing, wisping, etc.) Please don't get too excited, this duct is not a magic bullet to fix all the 3D printing problems you may have, it addresses very specific things in the areas of cooling and visibility that I wanted to improve. You must have a well-tuned workflow already (including slicer and mechanical) to see anything change to the better using this mod. Enjoy, hope this will be as much fun for you as I had designing and playing with it. Mac Feedback -------------------- It's free, so please, please - pretty please, take the time to provide me with feedback in return. :-) You can do that by simply posting a "Make" and telling your story, how you printed it and what your experience in using it was so far. I would love to hear back from you, so we can improve this thing even more, "together". :-) Update History -------------------- Current stable versions: - Taurus_V4.01-Stock_Hot_End.stl - Taurus_V4.01-Spider_Hot_End.stl - Taurus_V4.0-Spacer_Washer.stl Current beta accessories: - Extruder Visualizer Black No Stem 0.2mm.stl - Extruder Visualizer Black With Stem 0.2mm.stl - Extruder Visualizer Red 0.2mm.stl - Extruder Visualizer White 0.2mm.stl 06/27/2023 Version 4.01 Minor Maintenance Release The elongation of the mounting slots in the last release has weakened the mounting points a little, caused these to deform if the screw is tightened too much and to slip through the slot (1 report so far). Added more material around the ears to keep that from happening. 06/21/2023: Version 4.0 Official Release This version inherits all the new features from the previous spider alpha release and some more. Here are a few highlights: - Visibility of the nozzle is much better now, we spread the two tubes as far apart as possible. - Relaxed the first turn of the tubes a little bit, it now sits flatter on the build plate and prints better without supports. - We finalized a change where the original screws are meant to be used to mount this duct and rolled it into this release. - The mounting bosses have been elongated, there is now an additional 2mm adjustment possible in both the up or down direction. While that makes no sense in stock configurations, it helps a lot of makers that run custom hot ends. Again, the design is such that the bottom of the two jet nozzles sits exactly 1mm above the tip of the extruder nozzle. - Added a spacer/washer stl that you can print. Some have lost their original screws and used standard metric hex head screws instead, that causes the mounting bosses to deform. To counter that, we included a special spacer/washer that you can print yourself and insert three of these into the mounting bosses. - Added a "Taurus" letter logo to both sides of the body, confirmed that is printable and paintable. - Changed Taurus logo in the front to bold "V4" lettering. - Added an extruder visualizer in the shape of a taurus head, printable in multiple colors in the same part. Instructions how to achive this are following in a seperate section. 06/11/2023: The spider version is ready for alpha testing. There are a lot of changes in this that will flow back to the official design, soon. I had no way to test this, so please don't be disappointed, printing and testing this. Please provide feedback. - It aims at a virtual spider extruder nozzle at 3.5mm lower than the first stock hot end release, has the same geometry as before, just lower. - The tubes have been "spread apart" further, to hug the BLT some more, providing even more field of view, that looked very cool actually. - The problem with the strange artifacts in the transition from the fan geometry to organic has been found. It's now 100% smooth. - The attack angle of the jets has been changed from 18.5 to 18 degrees. We found that it was about 0.5mm too low for optimal cooling of filament that comes out of the extruder nozzle. - Added a Taurus logo to the front. 05/28/2023 Roadmap: Nobody has reported this yet, but a print of this component without supports in the recommended PETG material has a tendency to "leak" air through the layers. This problem is predominant in the area where it makes a sharp turn. The problem is amplified by printing it without supports and makes it leak even more. To combat that, the next version will have a slightly higher wall thickness for the tubular paths and I'm hoping that will seal these leaks. This may also be an opportunity to build a small built-in support gusset into the model to guide the printer better and add more adhesion during the printing process. 05/27/2023: Public Castle Preview - V3.1.1-beta - A lot of makers have already reported that the increased cooling that was added to their printers on the initial design has enabled them to print the follow-up versions completely without supports. I did not plan for this and could not believe this at first and tested it myself. Wow! I did not expect this to make that much of a difference, but almost all maker prints had a problem near the two outlet nozzles, with lines dropping out because that is a horizontal overhang at the end of the print. I found a way to fix this by adding a very minute gusset at 70 degrees to the tips of the nozzles, you can hardly see it, but it stops the final extrusions from dropping out, making this completely printable without supports. This release includes all the features from V3.1-beta 05/23/2023: Public Castle Preview - V3.1-beta - Corrected mistake in the documentation: "3x M3x8 screws" replaced by "3x M3x5 screws". This came from the Sorkin docs, they are too long. You can use M3x6, but this requires a washer. Let's fix this: - Countersunk the slotted mounting points so that the three mounting screws from the original fan can be used to assemble this duct, no extra M3 screws required! :-) - Added multiple fillets to reduce weight. - Reduced more weight by removing material between mounting points on the right. 05/22/2023: Released V3 - Initial Public Release Enjoy and please provide feedback, post a make!

With this file you will be able to print Taurus V4 Cooling Duct for Creality Sprite Extruder, Dual 5015 Fans, Ender 3 S1/S1 Pro/S1 Plus (Stock / Spider) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Taurus V4 Cooling Duct for Creality Sprite Extruder, Dual 5015 Fans, Ender 3 S1/S1 Pro/S1 Plus (Stock / Spider).