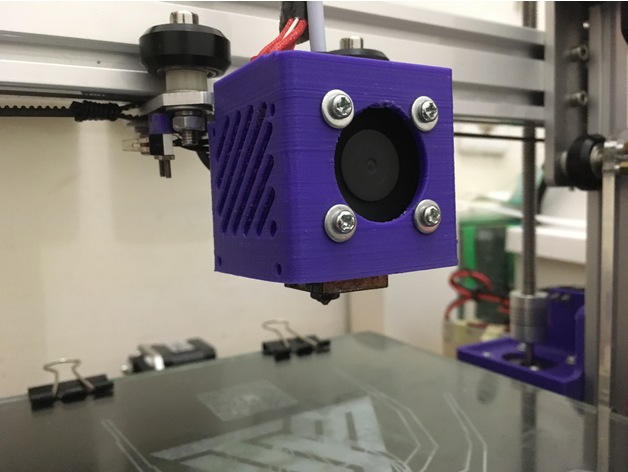

TEVO Tarantula Hot End Casing

thingiverse

Taking off bolts multiple times out of an aluminum heat sink could damage the thread. This casing I designed gives a protection from hot metal as well as provide mounting for possible deigned brackets. You can design your own mount based on the available holes. The hole is M3 diameter. The distance of the holes are match the 40mm fan and the 30 mm fan holes. They are about 32mm and 24 mm respectively. Also, it gives a neat look and better cable management. Print Settings Printer: TEVO Tarantula Prusa i3 - ReEngineered Rafts: No Supports: No Resolution: 0.15mm (best to handle hole) Infill: Any (1.3 mm thickness wall) Notes: I'm using ABS to handle the heat temperature on the heat sink. I found the slower speed the better to print the curve overlaps. I used 20mm/s for minimum speed. Good retraction setting is needed. Post-Printing The other side has holes for brackets, as well as the back. So you can attach fan shroud on the side or from the back. Dual radial fan brackets - Perfect for PLA printing How I Designed This I am using Autodesk Fusion 360 to design this housing. The gantry bracket that I used currently is the Fankhauser's modular aluminum carriage, which I put it up side down. The design is still in progress. I am upgrading the height. Feature Added: Dual radial fans bracket (remixed from: Supasorn's design - http://www.thingiverse.com/thing:1850163) - in this remixed, i adjusted the width and the trunks thickness (easier to print without support) Complete housing Case body Front view Right view

With this file you will be able to print TEVO Tarantula Hot End Casing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on TEVO Tarantula Hot End Casing.