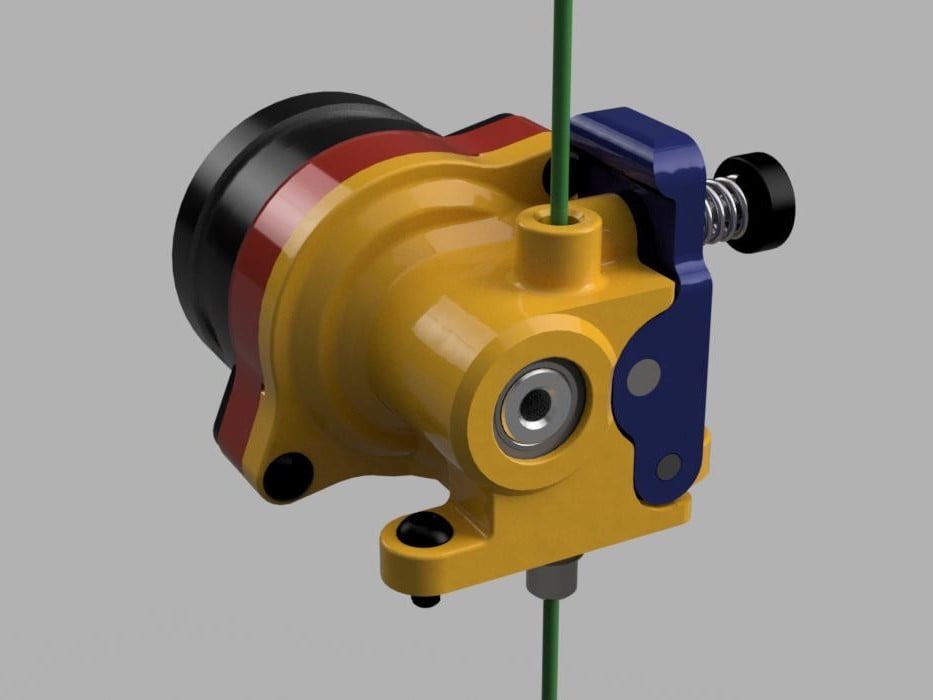

"The Orbiter" 140g direct dual drive Extruder with up to 10 kg pushing force

thingiverse

Hi everyone! This is my latest design, a high precision direct extruder using a planetary gearbox plus the big (12mm diameter) dual drive bondtech style gear-set. Short spek: - Gear ratio - 7.5 (new option 7.2) - Filament pushing force for LDO-36STH17-1004AHG 17mm stepper ~7.7Kg (7.5 gearing ratio, based on measured motor torque characteristics. The actual motor torque is less at lower operating current and RPM than the nominal max torque rating of the stepper). - Filament acceleration up to 660mm/s^2 - Retraction speed: 60mm/s - Overall weight is about 140g **Please do not run the LDO stepper above 500mA without proper cooling it can heat up too much and melt the SLS printed plastic gears** The orbiter printing @ 200mm/s on my MachCube 2.1: https://youtu.be/aZolOWtBbME In the last months I have experimented with worm gear based extruders with very good results, however not perfect so I decided to go for a different approach. What I have learned is that the worm gears are not the best choice for extruders. Although high gear ratio gives a good theoretical filament pushing force in reality this is not always true, mainly because the worm gear efficiency is pretty low. The plastic printed gears are even worse, at high torque their efficiency is well below 50%. The plastic worm gears tooth's are bending a little causing pressure variation in the nozzle which leads to some tiny wavy artifacts on the printed surface. 20-30:1 gear ratio reduces a lot this effect but the stepper will not be able to provide decent filament acceleration slowing your printed drastically down because it has to wait for the extrusion (this is the case for the Zesty Nimble, the flex3drive drive with Nema8 and my previous worm gear based extruders as well, acceleration below 100mm/s^2). Because of the above arguments I decided to go with a different approach, using a planetary gearbox (efficiency over 96%). In the same time I have changed from the small dual hubs (5mm) to the bigger ones (8mm) because the depth to which the hub tooth bites in the filament is more constant over different materials and print speed resulting a more accurate flow control. More teeths comes in touch with the filament. There is a slightly better grip on the filament resulting a more accurate extrusion. On the downside the bigger hubs ad more weight. **I have reached a license agreement with the following Authorized Manufacturers and resellers:** - LDO Motors as manufacturer and motor supplier - BluRolls Store on Aliexpress: https://www.aliexpress.com/item/1005001424760645.html?spm=a2g0o.productlist.0.0.369b72aaruh8Rg&algo_pvid=a0f43f6e-c791-4f69-9014-486c2606d0df&algo_expid=a0f43f6e-c791-4f69-9014-486c2606d0df-0&btsid=0bb0624516024086075523477eac37&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_ - Formbot Vivedino - Trodon version: https://www.formbot3d.com/products/direct-drive-dual-gear-extruder-for-troodon - Trianglelab reselling the formbot Vivedino version here: https://www.aliexpress.com/item/1005002029267359.html?spm=a2g0o.productlist.0.0.3f9857bfCH8Bub&algo_pvid=b3587a52-a689-41af-a699-7a8b011f00f9&algo_expid=b3587a52-a689-41af-a699-7a8b011f00f9-17&btsid=0b0a556416105456629541609e7400&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_ - Orbiter for CR10 stype printers: https://www.aliexpress.com/item/1005001732280318.html?spm=a2g0o.productlist.0.0.1b7857bf9qcAah&algo_pvid=bf448530-ebaa-475d-afb5-932e307255d8&algo_expid=bf448530-ebaa-475d-afb5-932e307255d8-6&btsid=0bb0620316053594425917628e0479&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_ The agreement with them is in such a way that they support me and the development of future Orbiter versions. By buying from them will support our efforts, Thank You!. LDO Motor Suppliers: https://fermio.xyz/voron/extruders/galileo/stepper-motors/118/36sth17-1004ahg https://www.printedsolid.com/products/ldo-nema-14-motor-ldo-36sth17-1004ahg?variant=32407962124373 **Some highlights of the LDO stepper:** - Is designed for a faster acceleration and direction change, essential for a good extruder stepper! - High temperature operation up to 180 degrees celsius; - Overall weight is about 70g (14g lighter compared to Wantai); - Long lead wires, so is easier to connect it directly to the printer mainboard without much hassle. The 65:27:10 I've chosen this combination to create a gap between the gears (0.15 clearance). I've uploaded an option with 62:26:10 gearing ratio which is a perfectly meshing gear combination. However due to the 0 clearance before using a pre-run cycle is needed to wear down the printed gears so they will run smooth. The gear ratio of this is 7.2:1. Be aware this variant requires very precise gears dimension, printing with 0.2mm nozzle or SLA, MJF is recommended.

With this file you will be able to print "The Orbiter" 140g direct dual drive Extruder with up to 10 kg pushing force with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on "The Orbiter" 140g direct dual drive Extruder with up to 10 kg pushing force.