TITAN_X_CARRIAGE_MOUNTS

thingiverse

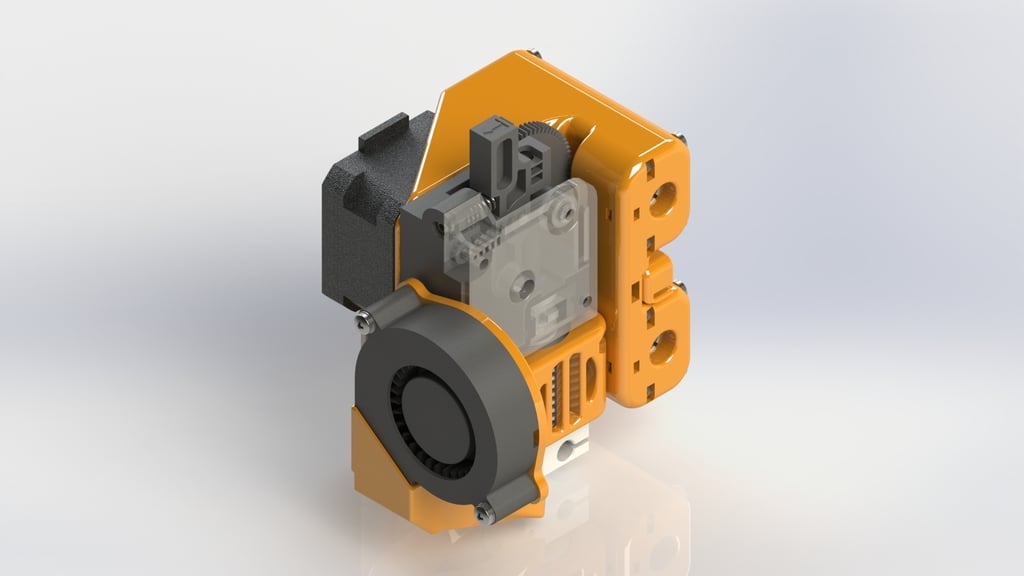

To improve the quality of my prints I decided to buy a TITAN extruder and since I could not find any support that convinced me I decided to design one. ==================================================================== **_IMPORTANT_** The distance between the bearing centers is **46mm**. It is fully functional on the _Anet A8 / AM8_ . ==================================================================== For this project I used the TITAN extruder of Trianglelab buying the SET 7 on Aliexpress (https://bit.ly/2tbjOFQ). The set includes: - Titan Extruder - 22MM stepper motor - 12V V6 Hotend full kit with Cooling Fan - 0.4 Nozzle - ALLmetal heat break In addition to the extruder set, you'll need: - 4x Igus RJ4JP-01-08 (https://amzn.to/2BntT6W) - 1x Noctua NF-A4x10 FLX (https://amzn.to/2RIyzJV) - 1x Fan 5015 12V Cooling Turbo Fan (https://bit.ly/2Gdq1JU) - 1x Noctua NF-A4x20 FLX (https://amzn.to/2MTM6xi) I have designed two different air conveyors (Fan_Duct and Radial_Fan_Duct), one for the Noctua and one for the 5015 fan, so it is not necessary to have both fans but just choose which one you prefer. In place of the noctua it is possible to use any 40mm fan. Below are a list of fasteners required: - 17 or 19pcs M3 nuts (the quantity varies depending on the choice of the fan_duct) - 8pcs M3 x 18mm (Even 16mm are fine) - 2pcs M3 x 16mm - 3pcs M3 x 12mm - 1pcs M3 x 20mm - 2pcs M3 x 45mm - 2psc M3 x 18mm (for Cooling Turbo Fan 5015) - 4psc M3 x 25mm (for Noctua NF-A4x20) The M3x18mm are used to fix the *x_back_1* and the *x_back_2* to the *X_Carriage* . The M3x12mm are used to fix the *belt* to the *X_Carriage* . The M3x16mm and the M3x45mm are used to fix the *Noctua NF-A4x10* and the *Back_1* or *Back_BL_Touch* to the *X_Carriage* . The M3x20mm is used to fix the *fan support* to the *X_Carriage* . All the pieces are already in the right print position. Supports are required for * X_Carriage *, * x_back_1 *, * x_back_2 * and the * Radial_Fan_Duct *. *Belt *, * Back_1 *, * Back_BL_Touch * and * Fan_Duct * do not need to be printed with supports. **Happy printing!** ==================================================================== _In the following sections you will find:_ - Print Settings - X_Carriage dimensions and Exploded - Supports - My Things ==================================================================== **_NOTE:_** It is recommended to set the new position of the origin within the software used. To set the new origin position you have to homing the axes and measure the distance between the nozzle and the angle of the bed and then change the parameters in your firmware. In Marlin you can set the position of the origin in Configuration.h (this is my position of origin, for your 3D printer will be different): < // @section machine < < // The size of the print bed < #define X_BED_SIZE 220 < #define Y_BED_SIZE 220 < < // Travel limits (mm) after homing, corresponding to endstop positions. **< #define X_MIN_POS -12.5 < #define Y_MIN_POS -5** < #define Z_MIN_POS 0 < #define X_MAX_POS X_BED_SIZE < #define Y_MAX_POS Y_BED_SIZE < #define Z_MAX_POS 230 If you are using Marlin then you can use a function to calibrate your extruder nozzle via "PID Autotuning“. More information can be found here: http://reprap.org/wiki/PID_Tuning

With this file you will be able to print TITAN_X_CARRIAGE_MOUNTS with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on TITAN_X_CARRIAGE_MOUNTS.