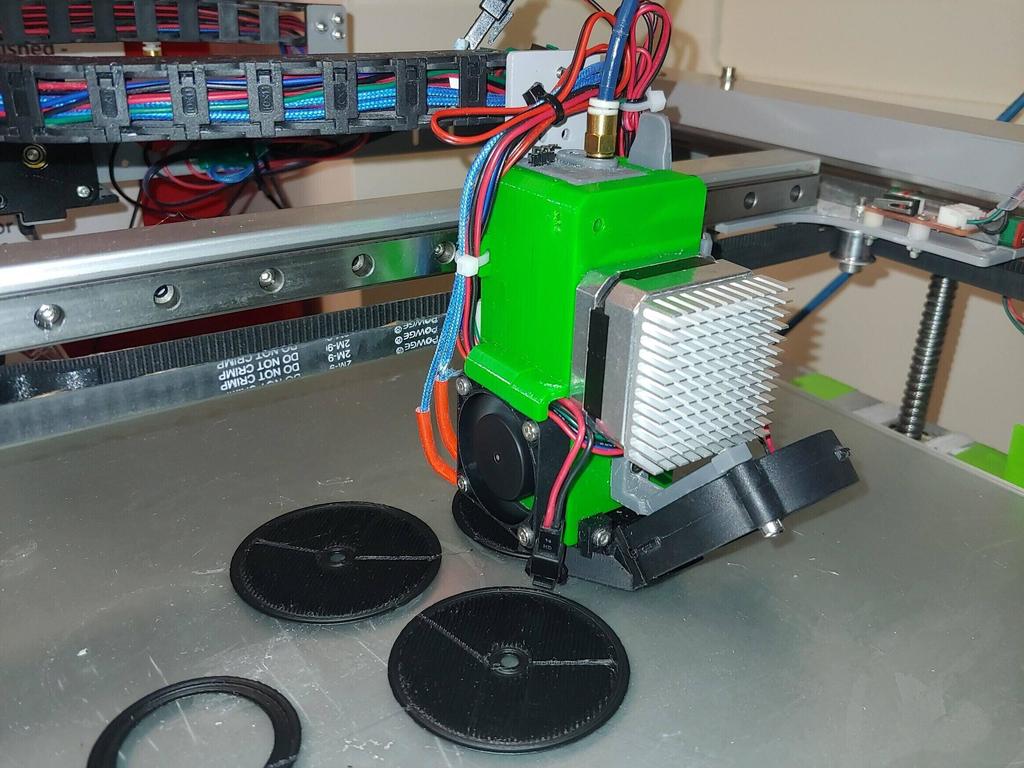

Tornado/MK3S Bondtech Geared Extruder-Direct Drive, BLTouch, Filament Sensor

thingiverse

This is a remix of the Bondtech Geared "Prusa I3 MK2.5S / MK3S Extruder upgrade" to work on a linear rail and the stock FlyingBear Tornado (Gen 1) steel carriage plate. https://www.bondtech.se/en/product/prusa-i3-mk3s-extruder-upgrade/ The original upgrade kit uses: - E3D v6 hotend - 25mm NEMA 17 pancake stepper motor (direct drive) - Inductive bed leveling sensor - Optical filament runout sensor - Part and heatsink cooling fans I have modified this to attach to the carriage plate mounting screws on the Tornado, allowing space for the carriage plate-carriage hex heads that stick out. I have removed the inductive bed leveling sensor and switched it to a BLTouch as most of us use glass beds. If you can afford it, I recommend buying the gears and parts from Bondtech, as they took the time to develop these excellent designs. Their build quality is also top-notch. [Upgrade kit](https://www.bondtech.se/en/product/prusa-i3-mk3s-extruder-upgrade/), [gears only](https://spool3d.ca/bondtech-drivegear-kit/) However, you can also purchase from TriangleLabs this [upgrade kit (option 1)](https://www.aliexpress.com/item/32998931899.html?spm=a2g0o.productlist.0.0.387d22aeSsUNRB&algo_pvid=6b2b0699-fae8-46ed-8d99-ef61d3e3ff06&algo_expid=6b2b0699-fae8-46ed-8d99-ef61d3e3ff06-0&btsid=0ab6f83915874206077021155e76c3&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_) and [gears](https://www.aliexpress.com/item/32947193804.html?spm=2114.12010615.8148356.1.62c4d2a7DkxZj3) The Tornado (Gen 1) steel carriage plate is used in this remix, along with the linear rail. This remix uses a BLTouch instead of an inductive bed leveling sensor, as most users have glass beds. You can purchase the gears and parts from Bondtech or TriangleLabs. Note: This is a work in progress. I would appreciate all feedback in the comments section. *Changelog:*

With this file you will be able to print Tornado/MK3S Bondtech Geared Extruder-Direct Drive, BLTouch, Filament Sensor with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Tornado/MK3S Bondtech Geared Extruder-Direct Drive, BLTouch, Filament Sensor.