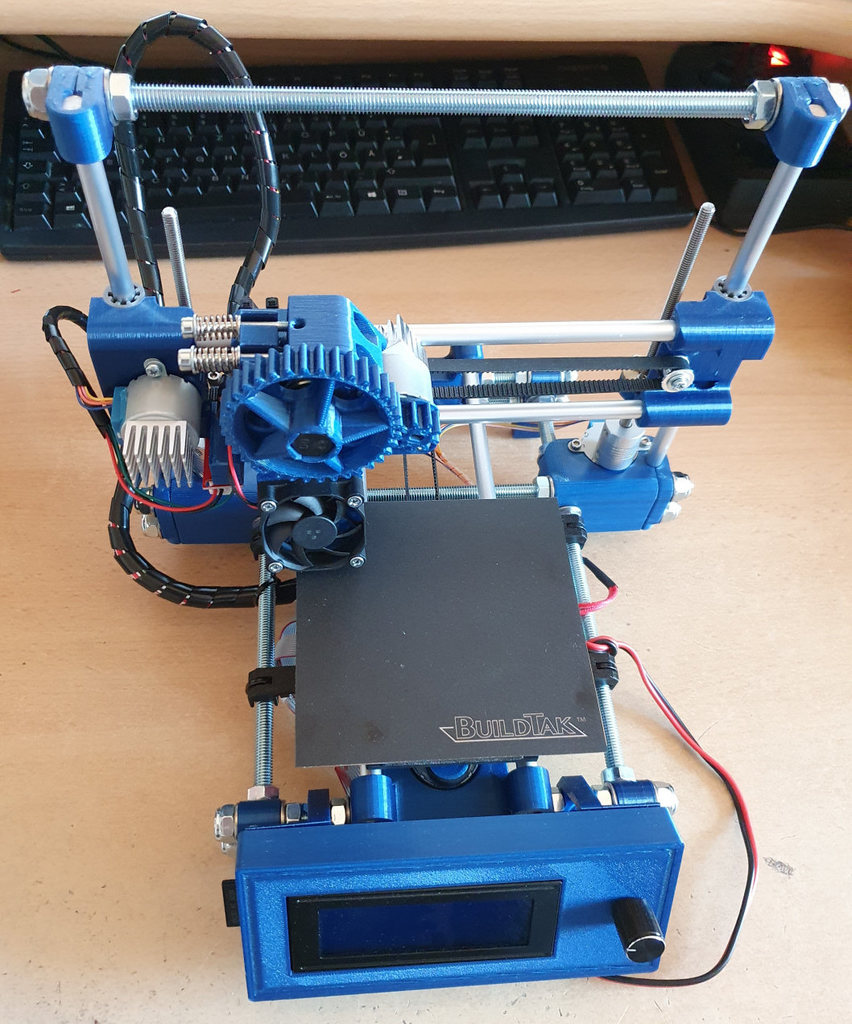

ToyRep RX

thingiverse

Remix of https://www.thingiverse.com/thing:945156 **ToyRep RX (aka RemiX) is my own take on the ToyRep design!** I love this printer design with its roots in the RepRap community and I decided to change a few details about the build. You can find a video of the first build here https://youtu.be/xRNCdrJooAo and of the later iteration here https://youtu.be/4r06BYtSB4M The machine prints slow, but at a consistent quality. The cheap stepper motors are the biggest concern with overheating. I build it to learn from the humble beginnings of the RepRap project and to have a novelty printer I can admire... This remix is not a cheap build, it uses rather expensive components such as TMC2100 drivers for all motors (with Vref at about 150mV) and a flexible build plate system among other details. It is a love letter to the original design, not aimed towards productive usage. Includes the fully configured firmware for the MKS Gen L 1.0 board (based on Marlin 1.1.9) and a tuned Profile for the IdeaMaker slicer (~20mm/s speed, 0.2mm layer height, 2mm retraction). **My goals were to...** o preserve the original look and feel of the design o streamline some aspects of the design for example fewer parts or better cable management o adjust for convenience features such as a removable build plate, display, part cooling fan aswell as the use of leadscrews o keep the same dimensions, all parts are interchangeable with the original design o this remix supplements the original ToyRep, you can mix and match parts as you like! I tried to capture as many details as possible of my build with the provided pictures. You can find all of the modified and most of the original stl files in the files section aswell as a 7zip archive of my OpenSCAD stuff if you want to modify anything! (Also contains STL files, as I'm mostly changing existing stuff...) **Design changes:** o changed X and Y Axis idler to a standard M3 GT2 belt idler pulley o added stops for the rods of X and Y axis, also ZMax clamps, so they dont move when not clamped in tight enough o added stops to the x and y carriages for the bushings so they don't move o replaced the stock hotend cooling fan with a combined clip-on hotend and part cooling one o added cutouts to Z, Y and extruder motor mounts for the heatsinks o replaced M5 nut with a leadscrew nut and moved the mount to the bottom to allow for shorter leadscrews to be used o designed a new board holder for the MKS board o extended the legs to make more room for cabling and general airflow o designed a display case and adapters to attach it to the frame, can also stand on its own o designed a new cable guide for the extruder and hotend cables of the x carriage o changed fixed endstops to clamp-on endstops o sligthly adjusted gear hex cutout dimensions for the hobbed bolt o tightened the pinion gear for the 28BYJ-48 stepper motor, it was very loose o tightened the gt2 pulley for the 28BYJ-48 stepper motor, it was very loose **Hardware changes:** o using an external 12V 5A (60W) power supply o using two T5 x 1 x 1 leadscrews + brass nut (Thread diameter 5mm, 1mm pitch, Lead - 1mm per turn) o switched to the MKS Gen L 1.0 board to make some space on the underside (about half the height of a RAMPS + MEGA2560 stack) o using M8 locking nuts o replaced the printed z-joints with proper flexible couplers o changed print surface to a BuildTak FlexPlate System (114 x 114 mm) o (using 3d printed bushings instead of the LM8UU ball bearings) reverted back to steel + LM8UU after sticky bushing problems! o (using aluminium rods) reverted back to steel + LM8UU after sticky bushing problems! o added RepRapDiscount Smart LCD Controller with SD Card reader o using standard Makerbot design endstops with led indicator o added heatsinks to all motors

With this file you will be able to print ToyRep RX with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on ToyRep RX.