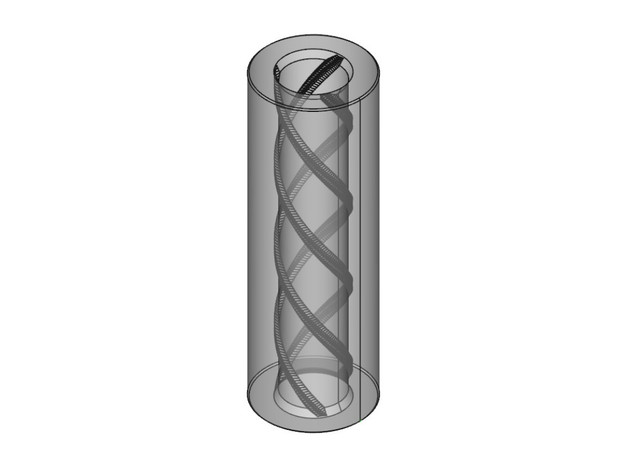

Traditional bushing 8x15x45mm (LM8LUU)

thingiverse

Traditional bushing for 8mm rods. Long version. : Don't use MoS2 grease for printed bushings, it's a fail. PTFE spray can oil works with PETG bushings if wiped dry after saturation. I have not tested silicon based or lithium based lubricants. I did look for graphite dry lubricant spray as a first choice but I did not find any in my vicinity so I chose PTFE spray can oil instead and as previously stated it seems to work if wiped dry after saturation. My first attemp to grease the Y-axis I used MoS2 dark grey grease, it worked sufficient for the linear ball bearings. When I used MoS2 dark grey grease to my printed bushings it did not work at all, tried it with PLA-bushings and PETG-bushings, they all seemed to work at first, but after one day or less they started to get to snug on the rods, they got stuck and the stepper motor struggeled with resistanse to move. NO GO for MoS2 grease and printed bushings! I printed a new batch of PETG bushings and tried them with sprayed PTFE oil (tens of thusands of PFTE balls per mm2, micro gap fillers), I used a threaded rod to grind the bushings to tolerance, moving the bushing back and forth along the threaded rod slowly rotating them both while applying pressure (using an 8mm drill bit might work better). Grind a while and the check the bushing against the bearing rod, grind a bit more etc. until satisfied with the tolerance. I found it to be sufficient if the bushing slides easy along the rod while dry, but sticking while wet with PTFE spray can oil. I grind the bushings until they just slide easy by them selves by gravity on the rods but sticks to the rod when saturated with PTFE oil. When satisfied with tolerance I saturated both the rods and the bushings with PTFE spray can oil, moved the bushings along the rods for a while and then thouroghly wiped them all dry with toilet paper, inside of bushings as well as whole of the rods. When saturated the bushings does not fall by gravity on the rods, they are sucked by viscosity to the rods, but when wiped clean they fall easy and fast along the rods! Lesson1: MoS2 dark gray grease works with linear ball bearings if applied inside the bearings. The linear ball bearings runs quiet and smooth with MoS2 dark gray grease (quality of bearings may vary). Lesson2: MoS2 grease does not work at all for printed bushings, neither PLA or PETG! At least not with fine tolerances between the rod and bushing. Lesson3: PLA might be partially dissolved by MoS2 and refined oils, I don't know, but it could be why the smoothness feels ok the first day but not the next day. PETG are resistant to oils and greases, or so they say. Lesson4: PTFE spray can oil works with PETG bushings if you saturate the inside of the bushings and on the rods with PTFE oil, move them back and forth rapidly by hand for a while and when done wipe them completely dry inside and out. Important to understand that if wet by oil (or grease) the bushings sticks to the rod by viscosity and boundary layer adhesion. Wipe everything dry using fresh toilet paper after saturated with PTFE spray can oil, remount and realign everything carefully and you should end up with a quiet linear PETG bushing heatbed. I did. From my, trial and error, pratical experience. /peen333

With this file you will be able to print Traditional bushing 8x15x45mm (LM8LUU) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Traditional bushing 8x15x45mm (LM8LUU).