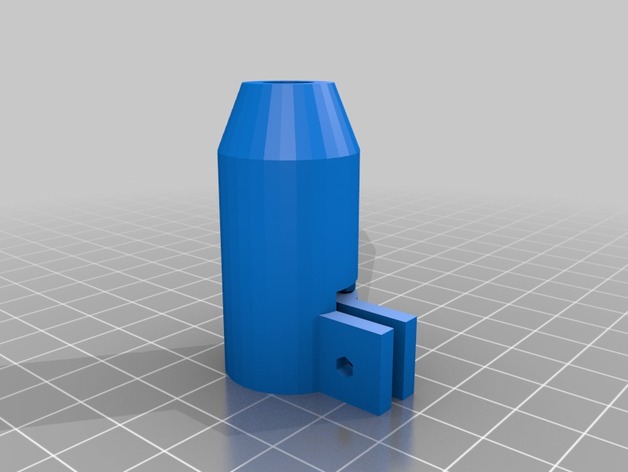

Traxxas 5247 to Carbon Tube Coupler With Compression Lock

thingiverse

This coupler was created to serve a specific purpose: to connect the Traxxas 5347 ball joints to 1/2" carbon fiber tubes for use on the large Delta style 3d printer I'm creating, based on parts and designs for the Mini Kossel. I'm using 24" long and 0.5" outer diameter carbon fiber tubes for the effector arms. So there is a bit of a "gap" between the Traxxas joint shafts, which measures around ~7mm in its outer diameter. The inner diameter of the Traxxas shaft takes an M4 threaded bolt. If you are building a large delta printer and are using Traxxas 4257 joints and want to use a large diameter shaft, this might be of help. Work in progress, so only uploading the STL at this point. I mainly designed this because I didn't like using glue and wanted something I can adjust/maintain. Hence this design. Update: Added a another STL, which does not have the little balls, for those who want to do their own support material. Also, after printing it, the balls really don't want to be removed. :) Though they will flex a bit to allow capture of the carbon fiber tube/rod. Note: The ridges in the photographs are due to ribbing on my printer(cheap threaded rod). A printer without the issues of my printer will print smooth walls. Instructions To connect this component: Print the part. I suggest 50% infill or 100% infill. Snap/break off the little ball supports. Clean any loose threads of plastic/etc. Insert the Traxxas shaft into the cone side of the sleeve. Take an M4 bolt, 5-8mm M4 should be fine. I would add a washer to distribute the pressure, but screw it in from the larger opening side of the coupler through the hole and into the Traxxas shaft. This secures the Traxxas ball joint to the coupler. Slide the 1/2" carbon fiber tube into the wide end of the coupler. Take an M3 bolt and M3 nut and slowly tighten the compression tabs to secure the carbon fiber tube. If you have a very thin sheet of silicone or other grippy/non-abrasive material as a sleeve between the compression ring and the carbon fiber tube, that would help. ** If you are concerned about the carbon fiber tube cracking under pressure, you can fit in a carbon fiber rod into the larger tube, making sure the clearance is tight. My carbon fiber tubes were 0.4" inner diameter, so I would need to get a 0.396" outer diameter rod/tube. YMMV. Test the strength of the connection by pulling/pushing. There should be no give. Rinse and repeat with the remaining effector arms and make sure they are all the same length. If all parts printed the same and all your rods are cut the same, this should not be a problem. However, if you do need to adjust, loosen the compression M3 and adjust until all rods match in length. A jig would help with this. Hints: A thin sheet of silicone between the coupler and the carbon tube/rod will work wonders for preventing slippage, if the compression of slippery PLA against slippery carbon fiber tubes doesn't prevent slippage. :)

With this file you will be able to print Traxxas 5247 to Carbon Tube Coupler With Compression Lock with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Traxxas 5247 to Carbon Tube Coupler With Compression Lock.