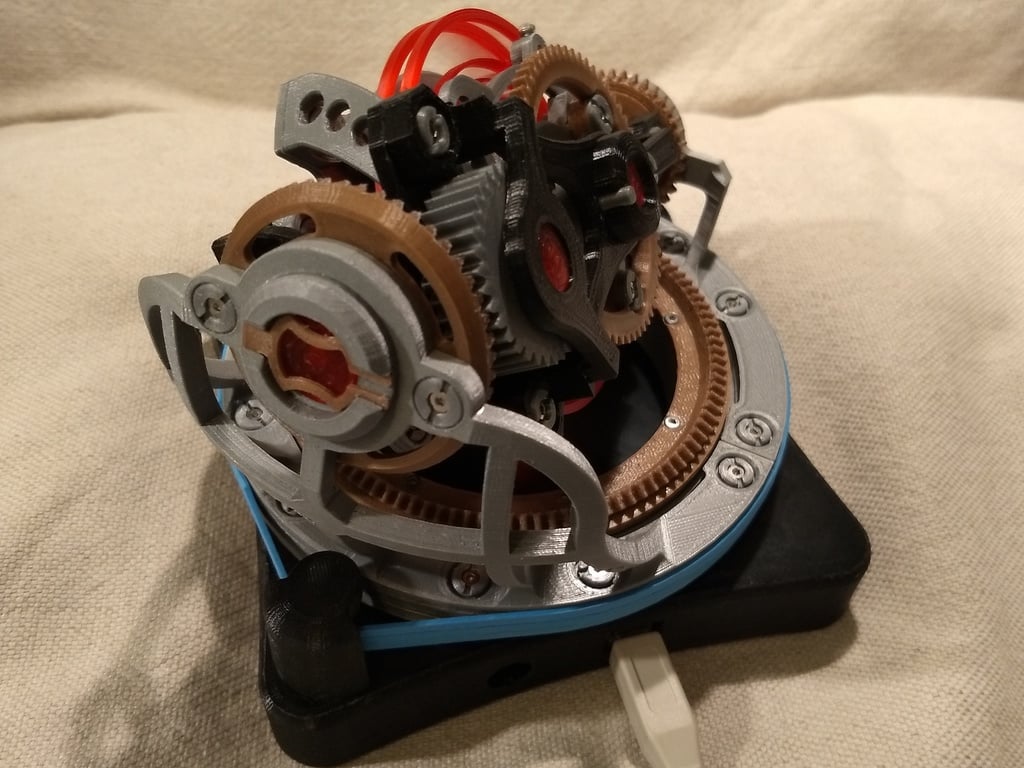

Triple Axis Tourbillon

thingiverse

This is my second clockwork design. It took just under a month from starting the design to posting it. I modeled it after a Cabestan Triple Axis Tourbillon, which they offer in their high-end watches. I spent many hours looking at YouTube videos of the watch. Similar to the Gyrotourbillon, I tried to make the model an accurate (scaled up) version of the original Cabestan mechanism. I printed screws to scale, then stuck a 2mm screw in their centers to hold it together. I also included Incabloc shock absorbers by printing clear red 'jewels', and working snap rings to hold them in place. This model is small, about 140mm in diameter. I power it with a 2A USB power supply. Here's a real-time video: https://youtu.be/Imm3mrR06tc This design moved so fast that a timelapse of it was just a blur. 12/16/19 Added L3_Ring_Gear.STL file to the File List. Corrected STL table in Notes, removing redundant files. 5/29/19 I posted a 'L1 Balance Wheel 2.STL' file that fixes an issue that was causing problems with calculating supports. 5/25/19 Posted updated Base Body that now provides mounting holes for the Stepper Pully Bridge. 5/24/19 Added L2 Idler gear 28T M1 to STL Files list in the notes. 5/19/19 I posted the pulley versions of the L3 Inner Bearing Race (L3 Inner Bearing Race 2a.STL and L3 Inner Bearing Race 2b.STL) and the Stepper Pinion.STL file. Apparently, I had the L3 Inner Bearing Race STLs for the gear-driven design, and the Stepper Pulley.STL for the rubber band-driven design. In my original design, the L3 assembly was gear driven, which is still illustrated in the notes. Gear drive worked fine for the Gyrotourbillon design, but I was having lots of problems finding the correct stepper speed for this Triple design. Too fast and the whole thing would bind up, and too slow, it would intermittently stop. A friend suggested using a rubber band, which led to the version that you see in the video. I recommend using the pulley/rubber band approach. That is, print the L3 Inner Bearing Race 2a.STL, L3 Inner Bearing Race 2b.STL, Pulley Bridge.STL, and Stepper Pulley.STL files. However, the L3 Inner Bearing Race a.STL, L3 Inner Bearing Race b.STL, and Stepper Pinion.STL files are included if you want to experiment with a gear-driven design. My argument is that the rubber bands provide two benefits. 1) The stepper can be set at a slightly higher speed than necessary, and the rubber bands will slip on the pulley if it's not the perfect speed for the movement, and 2) the rubber bands provide a constant tension, which works well with a movement that periodically locks its position while the balance wheel swings back and forth. If you turn the L3 turntable manually, you can feel the intermittent motion that gets transmitted to it by the escape wheel movement. The rubber bands stretch while the L3 rotation is locked, and contract when the escape wheel turns. Basically acting like a weight would in a weight-driven design. Both drive versions are now included if you want to experiment with a gear-driven design. 5/8/19 I posted the Stepper Pulley, Stepper Pulley Bridge, L3 Ring Gear a, and L3 Ring Gear b STLs, and renamed the 'L2 Balance Spring Adjuster' STL to 'L1 Balance Spring Adjuster' so the name matches the documentation. I also updated the Build Notes PDF accordingly. I was concerned that using supports would make the bearing race too rough, so the L3 Ring Gear is printed as two parts (a and b), then glued together so you don't have to use supports. Read the Triple Axis Tourbillon Build Notes PDF in the files for more information. Enjoy, McMaven

With this file you will be able to print Triple Axis Tourbillon with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Triple Axis Tourbillon.