Self winding pendulum clock (climbing weight for weight driven clocks)

thingiverse

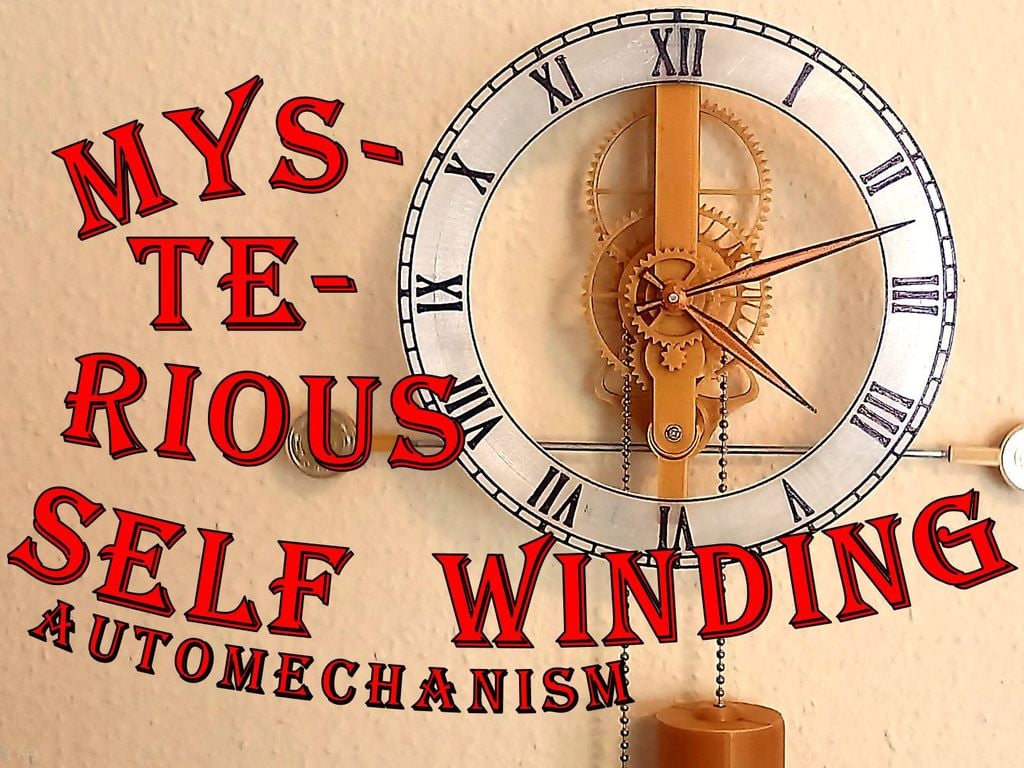

<font size="3" color="red">Please visit for original files, comments and updated info: https://www.thingiverse.com/thing:4828789</font> Currently Thingiverse does not offer a working "Download All Files" option. For downloading all the files at once, please click on the text below. It downloads a zip file with stls, images, etc. into the download folder: <form action="https://www.thingiverse.com/download:11235721"> <input type="submit" value="[Download All Files]" /> </form> <font size="4" color="darkgreen">**Don’t worry, if you forgot to wind up your clock. The clock itself will do it for you...**</font> <font size="4" color="orange">**More than 200 days runtime.**</font> <font size="3" color="black">Demo:</font> https://youtu.be/jV5sDiRVjcE <font size="3" color="black">Concept:</font> https://youtu.be/RdRMT0bqkko https://youtu.be/s17w4Eyq9Rc <font size="3" color="black"> **Abstract** I’ve wanted to make a pendulum clock for a long time, so I printed one recently. However, I seem to be lazy enough to keep this alive continuously and wind it twice a day (once if I would use a pulley bearing as a two-fall compound). That is why I made an</font><font size="3" color="DarkMagenta"> **automatic winding mechanism** </font><font size="3" color="black"> but not in the usual way. Instead, I redesigned the clock weight itself. Thus, a "hanging-only" part became an active component of the mechanism, supporting the operation of the clock. The modification requires only minimal changes to the clock hardware itself, virtually 99% of the original clock remains intact.</font> <font size="3" color="DarkMagenta">With this method, many 3D printed weight-driven clocks can be automated (even after completion) without having to delve deep into the structure of the clock. Big advantage that this winding method provides a constant driving force during winding too. Plus, it's all **completely hidden**, no one can recognize that the clock is automatized, the clock's traditional look remains intact.</font> <font size="3" color="black"> **The concept** The energy needed to operate the clock is still provided by the potential energy of a weight. However, the commonly used cord to hang weights is replaced by an endless metal ball chain. The chain is placed on the slightly modified winder drum and the weight "clings" to this chain.</font> <font size="3" color="DarkMagenta">During operation of the clock the weight falls slowly. **If the weight has reached the end of the chain, it grabs the chain and climbs to the upper most position fully automatically.**</font><font size="3" color="black"> The clock can also be wound up manually by pulling the other half of the chain in the usual way to lift the weight again.</font> <font size="3" color="black"> The weight consists of two separate and displaceable parts: the outer shell and the inner assembly-block (frame, motor, batteries, coin-weight, etc). The position of the free-moving outer shell relative to the assembly-block depends on whether the weight hangs at the uppermost position or at the lowest position on the chain. To detect this, a bi-stable switching mechanism is provided which switches the electric motor. If the weight is completely down, the chain will tension the outer shell up relative to the inner assembly and this actuates the switch what starts the motor. As a result, the weight begins to climb on the chain up until it reaches the bottom of the clock. The clock pushes the outer shell down relative to the assembly and the switch stops the motor. And the game starts again, the weight sinks with the chain until it reaches the lowest position then the weight climbs back to the top on the chain... It's so simple... written... but let's see...</font> <font size="3" color="black"> **The climbing weight** The weight includes a tiny cheap and easily available (Ebay / AliExpress / Amazon) geared electric motor. The energy for the movement is provided by 4 pieces 1.5 Volt batteries connected in series. The mass of the weight can be further increased with coins. The current version is designed to fit 21.3 mm diameter coins. So, the 5 Euro cents, the 5 USD cents, Mexican 1 peso or the 5 HUF fit perfectly. It can also be used with smaller diameter coins, but care must be taken to ensure that the ball chain does not reach the coins. The mass can be any other thing, putting them into a small plastic bag and placing it into the coin compartment. I put 2x15 pieces of 5 HUF in it, so the total mass of the weight is 320 grams. Actually, my clock runs at 200 grams too, I tried it, but it depends a lot on how heavy and long (inertia and forces) the pendulum is and how much friction there is in the clock’s mechanics (but YMMV). You can experiment ... I use a micro switch desoldered from a defect mouse, but this kind of switch is also easy to get from the online stores. I made the contacts of the battery holder from a ball point pen spring and drawing pins. The two shafts of the pulleys can be made from a suitable nail. The rod of the switch actuating mechanism can be a 3 mm diameter wood stick, or a rod can be printed out with the associated switch actuator. The whole mechanism is covered with a cylindrical shell, two halves of which adhere to each other with small magnets. This makes it very easy to disassemble and control the climbing weight. Instead of magnet, four pieces shafts placed into the hole of magnets as pin bolts are also suitable... <font size="3" color="darkgreen">**The clock**</font> <font size="3" color="darkgreen">The base of the clock I built earlier is designed by A26 (https://www.thingiverse.com/thing:1739676, One Plate Mechanical Clock) Credit to him for this. It is a nice minimal design clock, it shows the basic components needed to operate a clock, easy to print then assemble. I especially like this clock because the clock-face can be replaced with another look as you like, no need to disassemble/change/assemble the clock. I wanted to keep it itself as original as possible so that the gears / parts could still be seen during operation. https://www.thingiverse.com/make:929621 <font size="1" color="black"> Remix issue Thingiverse: https://www.thingiverse.com/groups/thingiverse/forums/site-issues-and-feedback/topic:48410</font></font> <font size="3" color="darkgreen"> *In order for the climbing weight to be used for other clocks, a ball chain gear of the appropriate size must be attached / mounted to the winding drum of the clock. The higher the number of teeth on the chain gear (diameter), the lower the weight required to drive the clock. A little help making the proper ball chain gear can be found here: https://www.thingiverse.com/thing:4851360*</font> <font size="3" color="black"> **Changes and remarks on the clock** The only change that is absolutely necessary to be able to operate the clock with a chain instead of a rope is described at the point 1. The rests are only needed because of the reliability or circumstances, e.g. I do not have any penny. The changes I made to the pendulum clock are:</font> <font size="3" color="black"> **1** The winding drum (drumb.stl -> CW_CLOCK_drumb.stl) has been redesigned so that the weight hangs on a ball chain instead of a cord. **2** A hole has been made throught the ratchet part of the drum (druma.stl -> CW_CLOCK_druma.stl) for a screw (=cotter pin) so that the ratchet cannot rotate on the shaft. Accordingly, an about 4mm wide flat part 27mm from the end was made on the 75 mm long shaft. This provides a more reliable force transmission than the grip and/or glue between the shaft and the ratchet. **3** A "top point stopper" (CW_CLOCK_stopper.stl) has been created so that the weight does not collide with the dial plate or the clock escapement when it climbs up. The stopper simply snaps onto the frame of the clock. **4** I cut a thread on both ends of the pendulum's rod, so I can easily fine-tune the balance of the pendulum and the time keeping accuracy of the clock. I also resized the coin holders of the pendulum (bobs, penweight.stl) to fit 100 HUF. Two coins are placed at each end. *To Hungarians: I didn't know it before, but with the same look, this coin exists in two different weights.* **5** Added a washer under the escapement wheel to avoid any collision between the wheel and the frame. **6** Pendulum bar (200 mm shaft) fixation improved, drilled a hole and added a security screw to the anchor. **7** I printed the "-v2" variant for wheel4 assembly. It requires an additional Ø3x16mm shaft but allows easier hour-hand adjustments in the daily use of the clock. Just medium grip needs between the shaft and the wheels. **8** I also modified the bearing nests on the frame because I had bearings of other sizes (11x5x5mm) at home. This stl is not included. <font size="3" color="black"> **The chain**</font> <font size="3" color="black"> The continuous operation requires an endless ball chain. For this, I printed a simple “cavity” tool (CW_TOOL_ball_chain_cavity.stl) so that the chain can be looped with a traditional combination pliers. Print two pieces. The chain section containing the opened bead should be placed between the two adapters. Then the adapters were pressed together with the pliers. In comments (answer for ADBZA) you can find additional info how to use them, and now (18.09.21) I upload some illustrative pictures https://youtu.be/wrloe5UoQ_0</font> <font size="3" color="Navy"> **Assembly of the weight and adjustment:** Detailed coming soon...after request Here are some points to help you set up auto winding: **1** There are two CW_Shell stl files. One for standing printing and the other for lying printing. Choose the one you prefer. Considerations for selection may include the quality and look of the printed surface, the amount of support, etc... The standing version is split in two and the upper center hole is also thinly filled so you don’t need support. Glue them together. Update: Animoose found the shell to be fragile. He used silk PLA for printing. It is known that many silk PLAs have poorer layer to layer adhesion than conventional PLAs. Therefore, I uploaded a new shell (filename marked with "strong") with a thicker wall and a rounded inner edge. So if you are printing with silk PLA, use this. **2** It is important that the ball chain does not get caught at the bottom of the outer casing of the weight. The bottom of the shell is curved so that the chain can slip freely on the surface when the weight is near the lowest point (end of the chain). The chain stops the shell but the inner assembly block can sink further with the chain. This moves the actuator rod upwards in the block and activates the switch. **3** Printing the assembly block requires support. To minimize wasted material, the assembly block is cut into two parts.The block weighs 43 grams and the support only 3 grams. Acceptable rate. After printing, the two parts must be glued together with superglue. Before gluing, it is advisable to lightly (!) roughen the surfaces to be glued with sandpaper. **4** Glue the switch to its place on the block. See the uploaded pictures, they show the preferred position/direction of the switch. **5** Adjust the position of the switch rod and actuator. The actuator is clamped on the rod but can be slid to adjust the switching point. The rod must come out at both ends of the block so that the outer shell can push it up or down. The actuator (CW Switch Actuator Rod.stl) can be attached to the rod in two ways (by rotating 180 degree). The two sides have different slopes. Choose what makes obstacle detection more reliable with your switch. If the actuator gets stuck at the edge of the switch, sand it gently with sandpaper. https://youtu.be/-hAkJKz3HoU **6** There is a small spring (formed from ball point pen spring) glued with a tape on top of the block. I had used a piece of soft rubber first, but then I found spring was more reliable. This somewhat compensates for the weight of the outer shell and ensures that when the clock weight starts climb upwards from the bottom point, the weight of the shell does not turn off the motor immediately. **7** Making the battery contacts requires a little skill, it may take several attempts but in 20 minutes everyone will be able to make it. Consider this time as learning something new, not wasted time :). I will upload a video about how I did. **8** The CW_ChainWheel.stl does not require support because the bottom of the center hole is filled. After print clean it. This wheel (sprocket) can be critical in term of fitting to the chain. (Many manufacturers, many size/ tolerance.) Therefore if you find that the wheel cannot drive the chain reliably, debug the operation to determine shrinking or zooming is necessary. Then print a new wheel with a slightly (-0.5%...+0.5%) resized dimensions in the slicer software. </font> <font size="3" color="black"> **Bom (non-printable components):** • 1 pc geared electric motor, GA12-N20, 6V, 30rpm https://www.aliexpress.com/item/33022320164.html • 1 pc switch, D2FC-F-7N https://www.aliexpress.com/item/32924769791.html • 1-3 m ball (bead) chain, Ø3.2 mm, ≈225 ball/meter (can be colored e.g. brass) https://www.aliexpress.com/item/4001148205301.html • 1 pc screw and nut, M3, min. 18 mm https://www.aliexpress.com/item/10000181324125.html • 2 pcs shafts Ø3x21 mm https://www.aliexpress.com/item/32297671032.html • 8 pcs magnets Ø3x6 mm (or 4 shafts Ø3x10-12 mm) https://www.aliexpress.com/item/1005001515842121.html • 1 pc flyback (snubber) diode to protect the switch. 1N400X or 1N4148, etc. • 4 pcs AA battery, 1.5V • 2 pcs ballpoint pen spring • 2 pcs flat head metal push pin • 15 cm wire • lots of coin • super glue <font size="3" color="black"> **Postscript** I have had the clock with the self climbing weight for about ten days. My ball chain was 3 meters long, so it hung about a meter and a half from the clock. With this length the weight reached the bottom point approx. every 12 hours and climbed back to the clock. With a shorter chain, the clock-weight would pull itself up more often. I wanted to see frequently how the weight climbs up, so I recently shortened the chain, now it hangs just about 80 cm. I have no idea how long the batteries and mechanics will last, so far I don’t see any problems. <font size="3" color="black"> **Update 30.04.2021** After roughly 3 weeks of continuous operation, the switch became intermittent because its contacts have burned out. I replaced the switch and soldered a flyback diode to the motor terminals to protect the switch against the inductive voltage spikes. Component added to the bom list. See photo about the installation. </font> <font size="3" color="black"> **Update 18.05.2021** It works. Nonstop. I have replaced the clock face and the hands. It’s been 40 days and the batteries still last. When the weight climbs, the terminal voltage of the batteries is 5.6Volts. This is only 0.5 V less than when I installed the clock. In previous tests, the clock weight climbed reliably at a voltage level of 3.5, so the batteries are sure to last another 3 months. <font size="3" color="black"> **Update 09.08.2021** The clock has been working continuously for 120 days already. I have never touched the winding mechanism except now for making a video for the forum. Battery voltage during operation is still 5.2V. It will definitely work for another two - three months. I added above (Assembly method...) a small explanation and a video how the switching of motor works. plus a new clock face has been uploaded. The diameter is larger (186mm) but the dial is slimmer than the previous ones. I think it’s nicer and better suited to the size of the weight. <font color="black" size="3"> **Update 28.09.2021**</font> <font color="Maroon" size="3">*Some archive / ripper sites, such as 3dmixers.com, automatically copies (rips) the contents (files/documents) of Thingiverse and then distribute them on their own site without providing a link to the source site on their front page. This is how they cut off the connection between the designer and the maker. I feel this is unethical. That way, I don’t get feedback on problems and suggestions, nor can I help/rework/update if needed. The makers cannot write and read each comments. That’s why I uploaded a notice to the pictures to draw attention to this fact….*</font> <font color="black" size="3">About the winding mechanism: It has been working for about a half year, no sign of wear, battery is still in good condition. :) About the clock accuracy: 6 mins gaining per week, details are here: https://www.thingiverse.com/make:929621 </font>

With this file you will be able to print Self winding pendulum clock (climbing weight for weight driven clocks) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Self winding pendulum clock (climbing weight for weight driven clocks).