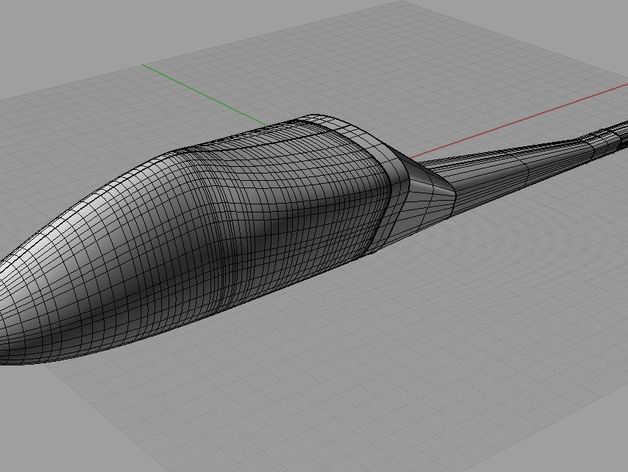

UAV fuselage 3D Printed in Nylon for Lightweight and Strength

thingiverse

I’ve started 3D Printing UAV fuselages for a friend that’s starting out in the hobby. He uses the “Bixler†type frames with some horizon sensors to get started. As we all know, there seems to be a greater number of tall obstacles as we start flying and it’s been no different for him. Having crashed several of his foam and foam covered planes, he asked for help. I’ve now printed about 5 fuselages of different sizes and different shapes, all based on the “Bixler†style he requested. These are 3D Printed as shown but in 3D Printing Nylon. They’re printed hollow and 3-4 perimeters. Due to being printed in a circular pattern, he is extremely pleased with the light weight and axial stability of the completed fuselage. Very little twist in 3 – 4 perimeter components. He is also very pleased that even with several rough landings and a telephone pole or two, he’s reported no damage at all due to nylon’s pliability and strength. Instructions These are 200mm tall, so make sure your printer can print this height. These are printed hollow or no fill in 3 to 4 perimeters. Each perimeter will add a slight amount of weight. At 3 perimeters, the completed part is stronger than most purchased foam covers planes. Axial strength is excellent due to circular printing. Nylon is much lighter than ABS/PLA and my friend say's the 3 layer is about the same as a purchased body. I've separated the print pad from the nose so you can add or edit. As the nose is attached at a small point to the table, it's important to get a good starting layer. I usually design such that there will be 4-5 solid layers and then hollow from there up. Stop the print before it trys to print a "top". Printing this way will create a lenticulated surface. At .16-.18mm height it's very slick. For larger layer thickness, you can spray the final part with a pliable acrylic coating to help smooth it out. The dia of each part is slightly smaller to fit into the others. this would need to change slightly as a function of the number of perimeters. This is printed with 618 nylon available here. www.taulman3D.com For additional assembly information, see:http://www.diydrones.com/profiles/blogs/uav-fuselage-3d-printed-in-nylon-for-lightweight-and-strength My UAV flying friend now has several more flights under his belt and very pleased with the new fuselages. The good news is that his current fuselages only have grass stains and some telephone pole tar on the nose and sides. The bad news is he’s out of wings!

With this file you will be able to print UAV fuselage 3D Printed in Nylon for Lightweight and Strength with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on UAV fuselage 3D Printed in Nylon for Lightweight and Strength.