underslung corexy FT5 mount

thingiverse

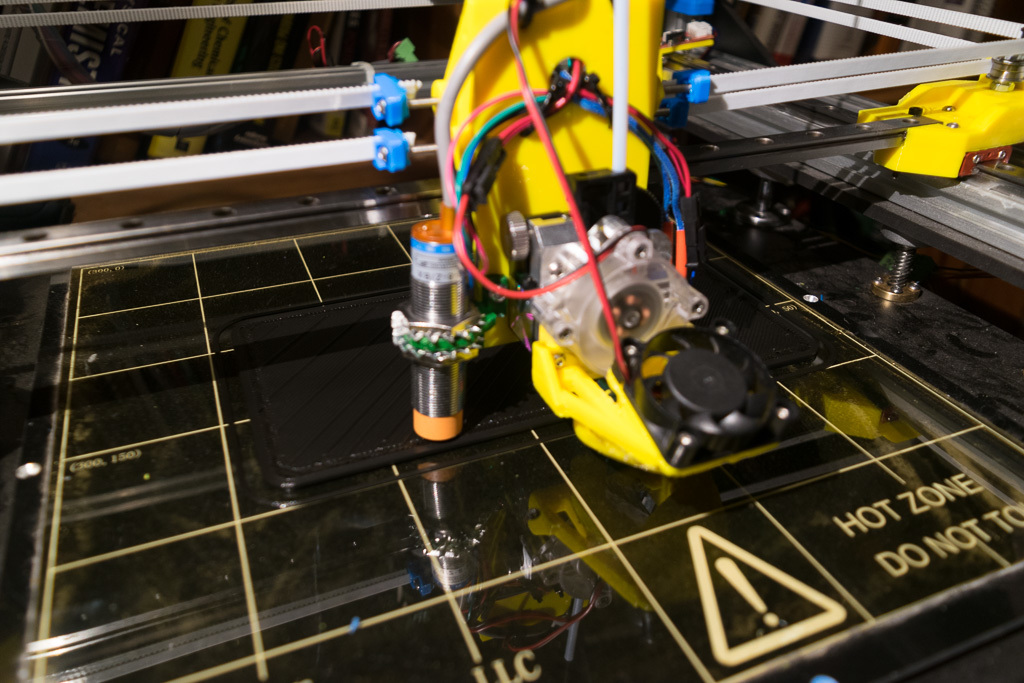

First off, I love Rajaa's CoreXY conversion - it is simply brilliant! I was prepping for it myself when I realized I'm an absolute numbskull and didn't read the instructions about needing a long nozzle. Obviously, a Titan Aero wasn't going to cut it. I'm also in a rather primitive country so M3x60mm for plate standoffs aren't readily available and I ordered the wrong type which were partially threaded, and shipping costs an arm and a leg. Then I checked out how much it costs for a long E3D nozzle (Volcano or original V6) and got frustrated with myself for being a double idiot. Then I had a lightbulb moment and realized I could just make an underslung extruder mount by duplicating the mount plate for the stepper underneath. I gave it 20mm of clearance for the slider rail which gives it just enough room for a regular NEMA 17 body under the rail, with wires going out to the side. The underslung mount removes the need for the bed spacers and long bolts for bed standoff as this provides enough margin against the Y-rails+2020 extrusion thickness for a Titan Aero. I'd imagine most other hotends are longer than this so there won't be an issue. Since it is underslung and not reinforced in any way, because I am absolutely terrible at even kid level Tinkercad, I'd suggest not hanging one of the big FT5 original steppers (5kg/cm) on it, since that may have lots of Y-vibration and you will need long bolts. I'm using a pancake stepper with my Aero and some of the original FT5 assembly bolts since they are long enough so additional screws weren't needed. Also due to the change in extruder from long nozzle to short Aero the cooling duct from Rajaa doesn't work as it is too tall (edit - see his comment below, a new version is available which will work with short extruders. don't use mine). I did a completely grotesque remix using a couple of parts, Rajaa's original duct, and more horrible Tinkercad. Apologies for offending design sensibilities... No extra holes are provided for BLtouch/inductive probes. I figure everyone doing this kind of conversion can punch their own holes in the STL provided or use a drill to make their own mount to spec. Cable management is left as an exercise to the reader. Mine isn't too horrible for now. Again, all credit should go to Rajaa - thanks so much! The original design for the FT5 is kind of kludgey with the woodcuts and prone to vibration which loosened the X-mount for me and led to a failed print once. This redesign is ahhhmazing. My test suggest ~400mm/s linear motion is possible before X/Y start to skip. I will easily be hotend limited going forward. Maybe I'll get that Volcano after all :). (Updated the nozzle, I accidentally punched a hole in it with TinkerCad with the triangle...)

With this file you will be able to print underslung corexy FT5 mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on underslung corexy FT5 mount.