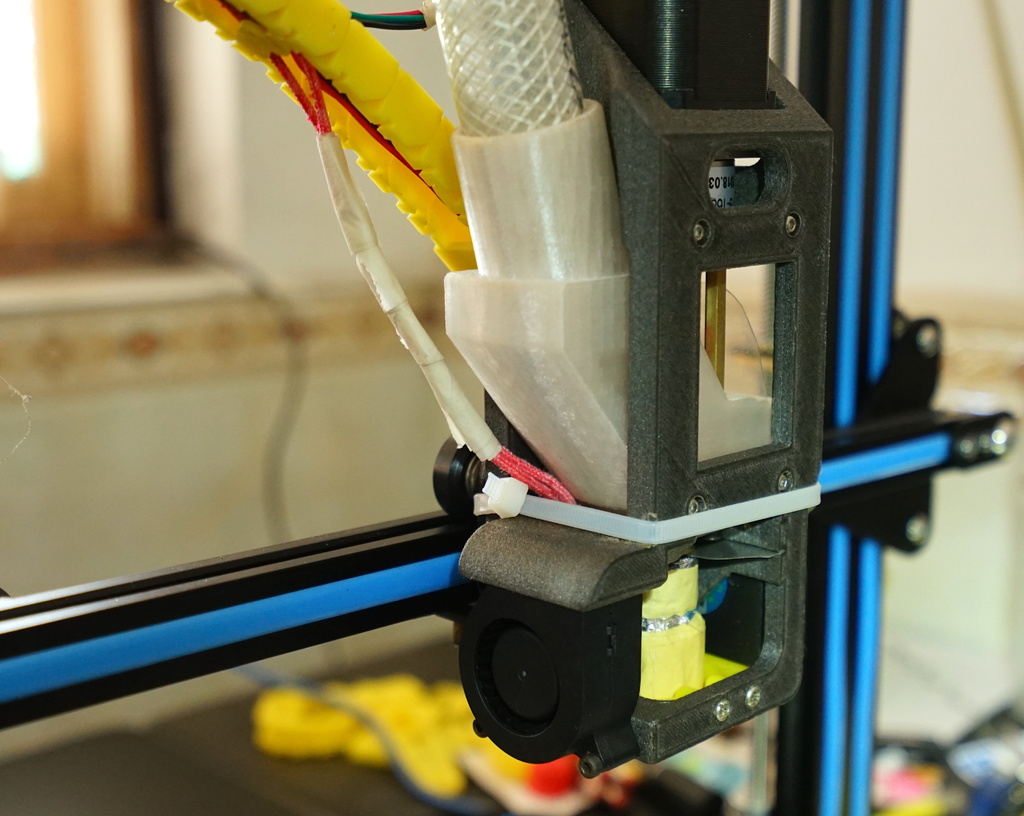

Universal Pellet Extruder V3 ZQ version

thingiverse

27/03/19 I'm still experiencing issues with the hopper feeding, even after repeated prints. It always stops at the same spot where the feed stock creates a void around the screw, resulting in a dome-shaped cavity. If anyone else is facing this problem and has suggestions to fix it, feel free to message me or share your ideas on the forum: https://www.thingiverse.com/groups/universal-pellet-extruder/forums/general/topic:31485 10/01/2019 I'm marking this design as complete, as it's now printing flawlessly. Additionally, I've added detailed assembly instructions to the git page: https://github.com/ebenfarnworth/Universal-Pellet-Extruder-V3-ZQ-version/wiki/Instructions-for-assemble 04/10/18 This hopper has been successfully used in building nodes for an 8m bamboo geodesic dome. The project can be viewed here: https://www.thingiverse.com/thing:3135801 I've replaced the stock 0.8mm head with a 1.2mm head, which works much better with bottle PET. 16/08/18 To prevent feed stock from getting stuck in the extruder when printing with shredded plastic, I designed a feed stock stirrer that can be downloaded here: https://www.thingiverse.com/thing:3051987 06/08/18 After revising the design, I was able to reinstate the left side pillars and found that my feed stock still flows through to the extruder just fine with my rotating wire rod. This has been working well for me, so feel free to try this revised design if you're feeling adventurous! The hopper was printed at 0.16 resolutions, 25% infill in PETG, while the housing was printed at 0.26 resolutions and 35% infill. 02/08/18 **IMPORTANT** This design failed for my specific use case. When printing at 270 degrees with a fan always on, the case became soft and warped from excessive heat, jamming the extruder. I'll need to make some changes before uploading any revised version. Feel free to share your ideas or suggestions in the comments. Discussion group: https://www.thingiverse.com/groups/universal-pellet-extruder/forums/general/topic:31485 This design is a complete rework of Mahor's pellet extruder v3, and I'm trying to overcome several challenges with this new version: Stability - The original design was prone to wobbling and flexibility when mounted on the CR10. To address this, I've designed a 3D printed solution that provides stability. Dust and mess - When printing with shredded plastic, bits of plastic would get blown everywhere due to active cooling. To prevent this, I've relocated the cooling system in this new design. Prevent blockage - Shredded plastic has high friction and is prone to clogging. To mitigate this issue, I've designed a new hopper that minimizes blockages. Easy mounting on CR10 - This new design allows for easy mounting on my CR10, which was not possible with the original design. The design also has some drawbacks, including increased weight, difficulty in printing, and more post-processing required. However, it's worth noting that I've printed parts with tree-type supports, which were relatively easy to remove (PETG doesn't like bridging). If you print this hopper, you'll still need the original part cooler fan ducked from here: https://www.thingiverse.com/thing:2506666, as this is an alternative printed set of parts for this extruder: https://mahorxyz.wordpress.com/2016/05/02/pellet-extruder/ Licensing note: The GPL license applies only to the two parts I've created here and the CR10 it's mounted on. The hardware for the Pellet Extruder is not subject to the GPL. FreeCAD files can be downloaded from here: https://cloud.zenquest.co/index.php/s/MeSmmWGivdPe6Io I'll move everything to git-large-file-storage once I've set it up: https://github.com/ebenfarnworth/Universal-Pellet-Extruder-V3-ZQ-version Note: I worked on one file until FreeCAD became too slow, so I copied the shape to the next file and continued working that way. There are currently 5 files in various stages of design development, and they're all quite messy!

With this file you will be able to print Universal Pellet Extruder V3 ZQ version with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Universal Pellet Extruder V3 ZQ version.