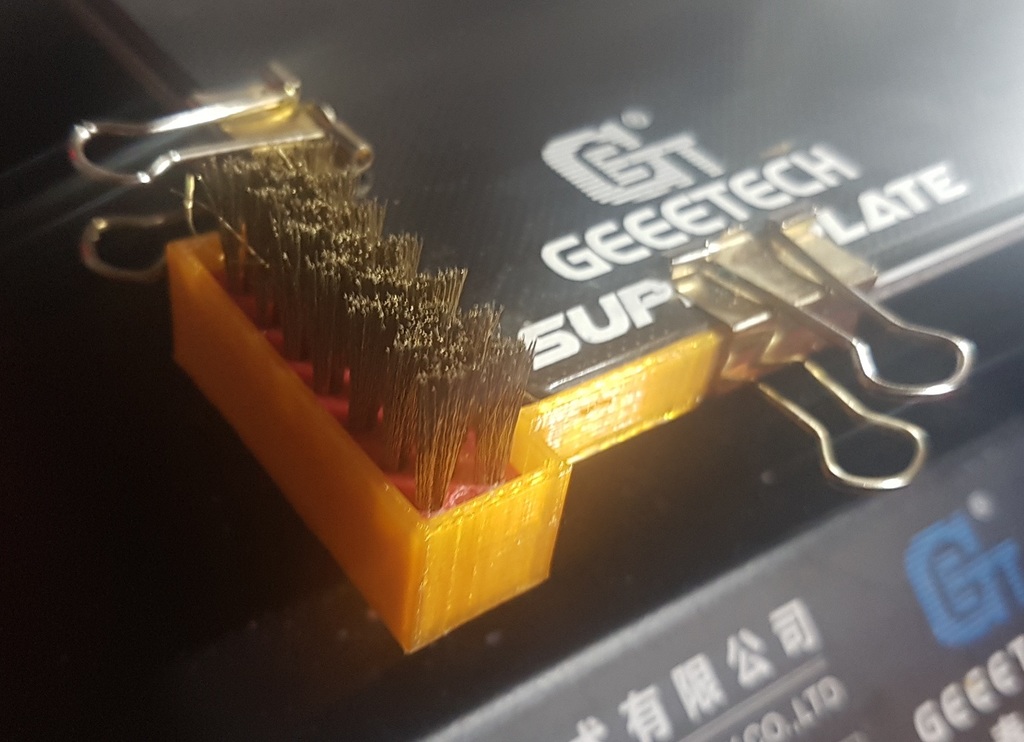

Universal Wire Brush Holder for automatic nozzle cleaning

thingiverse

I couldn't find any wire brush holder that was suitable for my 3D printer, so I designed my own. Using binder clips was the easiest way to attach one. That makes this model semi-universal, and should fit most printers. My bed is about 7 mm thick, and I use small binder clips which are just the right size for it (19 mm wide, by about 7 mm thick) Thinner beds should work too, as long as the binder clips are a similar thickness, as the ends that are held by the binder clips are also 7 mm so that they are held in place securely by the clips. The brass wire brush heads I use are around 12.25mm wide x 40mm long x 9.75mm thick at the base. Yours will need to be around this size. If it's smaller, you can glue it in place. There is 0.1 mm clearance on all sides and the brush fits snugly and should not come out easily. The brush base is recessed by 5 mm below Z 0 to prevent accidents. v3-Straight can be placed anywhere along the sides of the bed and is designed to sit flush. v3-Corner is designed to sit on the front left corner, and sits flush with Y 0 and with the side of the bed, but can be mirrored to fit on the front right corner instead. v4-Corner-Extended is the same as v3-Corner, but is extended out from the front by 5 mm, so it starts at Y-5 instead of Y 0. This is the version I use, as with v3-Corner the farthest binder clip knocks into the frame when I move the bed inwards, with 5 mm extra space there is just enough clearance. I recommend using this with the Marlin G12 Clean Nozzle feature, but you can also make your own custom nozzle cleaning G-Code to put in your start script. Here are my Configuration.h changes for Marlin G12 Clean Nozzle. Take care with the minimum X and Y positions of your printer, mine goes to -10 and -5 respectively but yours may not go that far. These settings are for v4-Corner-Extended. With these settings, simply put "G12 P1" somewhere in your start script (preferably after priming the extruder by extruding a bit) ~~~ #define NOZZLE_CLEAN_FEATURE // Jdbye edit ON #if ENABLED(NOZZLE_CLEAN_FEATURE) // Default number of pattern repetitions #define NOZZLE_CLEAN_STROKES 2 // Jdbye changed to 2 from 12 // Default number of triangles #define NOZZLE_CLEAN_TRIANGLES 4 // Jdbye changed to 4 from 3 // Specify positions as { X, Y, Z } #define NOZZLE_CLEAN_START_POINT { -10, -1, (Z_MIN_POS + 4) } // Jdbye changed Z from +1 to +4, X to -10, Y to -1 #define NOZZLE_CLEAN_END_POINT { -2, 31, (Z_MIN_POS + 4) } // Jdbye changed Z from +1 to +4, X to -2, Y to 31 // Circular pattern radius #define NOZZLE_CLEAN_CIRCLE_RADIUS 6.5 // Circular pattern circle fragments number #define NOZZLE_CLEAN_CIRCLE_FN 10 // Middle point of circle #define NOZZLE_CLEAN_CIRCLE_MIDDLE NOZZLE_CLEAN_START_POINT // Move the nozzle to the initial position after cleaning #define NOZZLE_CLEAN_GOBACK // Enable for a purge/clean station that's always at the gantry height (thus no Z move) //#define NOZZLE_CLEAN_NO_Z #endif ~~~

With this file you will be able to print Universal Wire Brush Holder for automatic nozzle cleaning with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Universal Wire Brush Holder for automatic nozzle cleaning.