Upgraded spring mounting plates for Emaker Huxley and nicrome rework

thingiverse

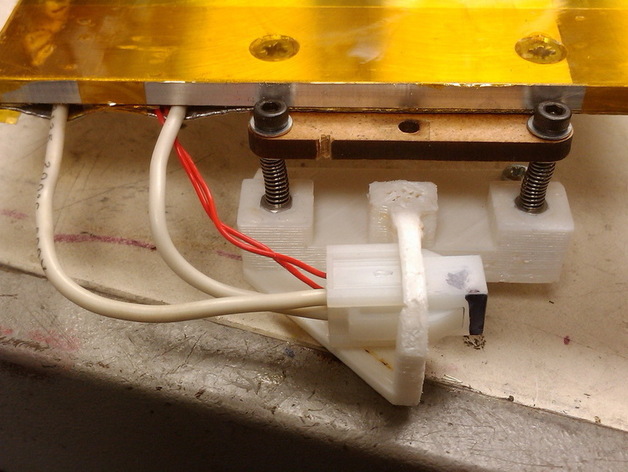

These two mounting plates replace the existing mounts on the Emaker Huxley to eliminate shaker in three mounting screws and provide a solid hold for heated bed connectors. Photos display heatbed with burnt-off insulation, detailing the redo process. After printing these pieces, clean M3 screw holes and insert standoffs in hexagonal sockets using M3 nuts and washers. Install wires and pins in Molex connectors before securing them. When attaching the bed, keep M3 nuts on screws for adjustment locking with superglue as reinforcement. For the best nicrome connection, strip wire end, sand lightly, apply plumbing solder flux, tin with lead-free or 60/40 plumbing solder, wipe off excess, clean with rubbing alcohol, and crimp onto an uninsulated terminal. Ensure strong wire pull before soldering using lead-free electronics solder and silver tin alloys. Apply fiberglass tape between the bed and nicrome wire for heat protection, followed by Kapton tape and thermal insulation.

With this file you will be able to print Upgraded spring mounting plates for Emaker Huxley and nicrome rework with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Upgraded spring mounting plates for Emaker Huxley and nicrome rework.