V groove bearing pully

thingiverse

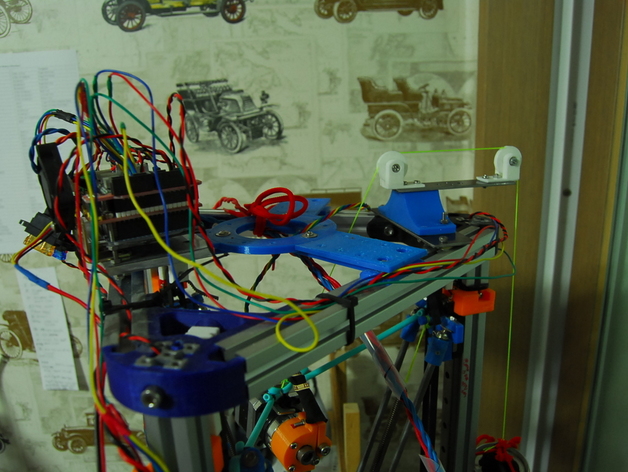

Parts: Pully support x1 (printed part) V groove wheel x1 (printed part) 623Z bearing x1 (OD 10mm, ID 3 mm) M3x15 bolt x1 M3 nut x2 M3 washer x2 Assembly: The inner diameter of V groove wheel is set 4.8 mm to press fit the bearing. I used press fit technique. To press fit the bearing into the wheel, heat up the bearing for three to four seconds using a portable gas torch or lighter. Then push the bearing into the hole, press it by C clamp or bench vise. To use M3 set screw, change the diameter of bearing_623Z() to 5.0. module bearing_623Z() { cylinder(r=4.8, h=4+2); // 4 } Put two M3 washers in left and right side of the V groove bearing. Fasten the V groove bearing on the support using M3x15 bolt and one M3 nut. The V groove wheel should turn without rubbing the inner wall of the support. Print Settings Printer: Bulbul Junior Rafts: No Supports: No Resolution: 0.2 mm Infill: 30% Notes: Print the support and V groove wheel at the same time. My counter weight of flying extruder uses two pulleys. How I Designed This Pulley of the counter weight system Previous pulley that uses 623Z bearing made the string digging into the gap between the bearing and support while in printing. So I went out to buy V groove bearings in local suppliers. I went home with great frustration. 'Why should I buy this kind of simple part from other country?' I decided to build a V groove bearing and searched models on thingiverse, and found one but it was overly complicated. After studying the SCAD design, I borrowed core design, merging two identical cones at the center. Press fitting 623Z bearing into the V groove wheel makes V groove bearing!

With this file you will be able to print V groove bearing pully with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on V groove bearing pully.