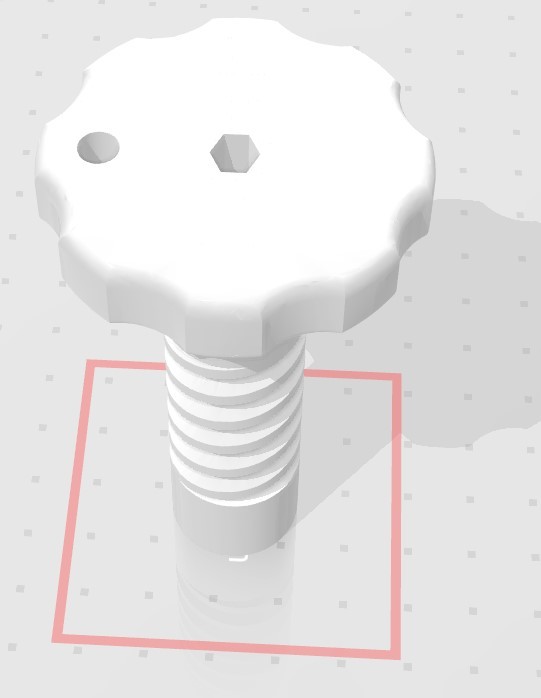

Vice mechanical v2.0 (drill bit adapter)

thingiverse

My vice turned out great, with only minor problems to fix. I used my angled cutters that came with my printer to clean up the threads and ensure smooth rotation. By putting my drill on the screw holding the worm gear (hand crank) and turning it clockwise quickly, I was able to run through the gears and knock down any rough spots, making it easier to turn by hand. Note: When referring to the screw on the underside of the vice that goes through the spacer to hold the worm drive, keep this in mind. Eventually, I encountered a stripped screw, so my drill wouldn't turn it. To overcome this, I created an adapter to put a drill into the top and turn it back and forth quickly, cleaning the gears and speeding up progress. This should be done after running the drill through the gears' endpoints; afterwards, I applied Teflon lubricant for effortless handling. I chose Teflon lubricant because it repels dirt and remains mess-free. Hopefully, this will help someone out in the future; I haven't printed my vice yet but plan to test it soon. Unlike others, I believe the gearing on this vice is exceptional, requiring patience but providing great power. I recommend printing the gears at 100% infill for increased strength when using a drill. I'll be utilizing my vice for soldering chips and RC projects. If you need an additional adapter style or adjustments, feel free to let me know. Thanks are also due to this creator for their excellent work on this design!

With this file you will be able to print Vice mechanical v2.0 (drill bit adapter) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Vice mechanical v2.0 (drill bit adapter).