Wade Mise En Place

thingiverse

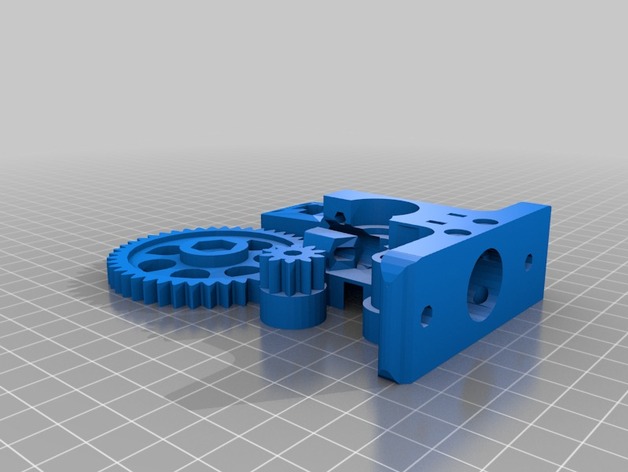

Everything for a Wade-style extruder one printable sheet. Probably a bit big for makerbots but fits a Mendel or Prusa build area. Suits 3mm filament and uses a zip tie idler hinge. Instructions The standard STL is for an 18mm diameter PTFE or PEEK hot end insulator, held in place with 2x wood screws instead of glue to facilitate repairs. The body has been thickened near where the screws pass through to prevent embarrassing melt-outs. Cooling the insulator with a fan is still highly recommended. I've beefed up the filament guide as the original seemed a bit delicate and I broke it too easily. The idler has been remade with notches to allow attachment with zip ties. This is highly recommended as the original hinge holes frequently split, and it removes the need for springs. It needs: 18mm dia insulator hot end, 3 x 608 bearings, M8 hobbed drive rod, NEMA17, 2 off M3x12, 4 off M3 washer, 6 off M3 spring washer, 2 off M3 nut, 2 off M3x40, M8x16 rod, zip tie, 3 off M8 nut, M8 half-nut, M8x25 washer, 3 off M8x16 washer, 2 off 1 in. #6 woodscrew. See the picture of the opened extruder for details on how to string the rods and fasteners together. Other photos show how to use 2 woodscrews to hold an extruder, and how to assemble a Blowout Preventer plate (3mmx28mmx25mm aluminium, central M6 hole, 2x3mm holes on 22mm centres using 2x25mm M3 to fix to hose clamp).

With this file you will be able to print Wade Mise En Place with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Wade Mise En Place.