Wheeler

thingiverse

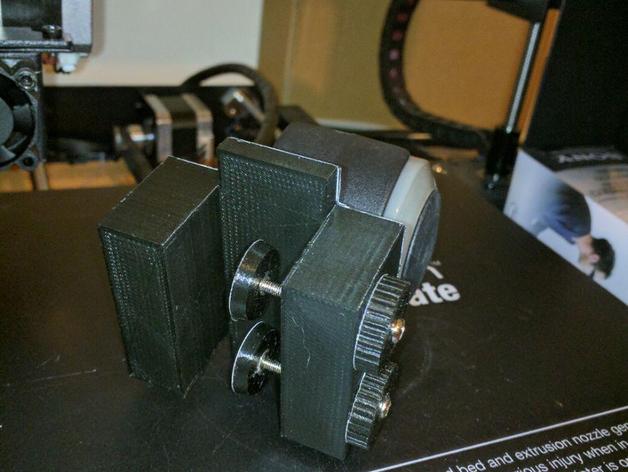

For the single guy that wants to move a wardrobe but not bother his friends. Clamp these to your wardrobe and just roll with it. You'll need 4 Prints of Base 8 Prints of Knob 8 Prints of Pad You'll also need 8 m3 x 30mm bolts 24 m3 nuts 16 8G by 16mm timber screws (well they've worked for me, might want to try 6G) 4 castor wheels For the castors I used 50mm x 53mm soft finish castors with a 42x42mm fitted plate. They have a max load of 30kg per castor and 90kg maximum total. I wouldn't suggest going anywhere near that with printed plastic parts. Print Settings Printer: Prusa I3 Clone Rafts: Doesn't Matter Supports: No Infill: 40% Notes: I printed with rafts just to ensure good bed adhesion, and I used 40% infill for more strength (these are probably the heaviest thing I've ever printed) Post-Printing Installing Nuts Tolerances are pretty tight on this print, I had to use a clamp to force the nuts into the captive holes. Put nuts in every captive hole you can find, there should be two in each Base, one in each Knob and a further one in each Pad. It pays to thread a smaller m3 threaded screw into the Knob nuts and use that to force them deeper, it gives you a few extra mm of clamping ability. Install the bolts Thread the bolt fully through Knob, from the nut side to the flat side, I put a little bit of Loctite on it before screwing it home. Thread the bolt through the outside of the Base (this should just slip through but might require some turning) and screw into the nut on the inside of the Base. Apply a little Loctite inside the nut on the Pad (I also used some CA to help hold the outside, not sure how that'll hold) and screw that onto the protruding end of the bolt inside the Base. Set aside for the curing time of Loctite Apply castor wheels So, I made the castor wheel holes in the Base a touch further apart than they needed to be for my castors so I could put the screws in at a slight angle making sure they don't put too much pressure on the inner wall (which is probably a touch thin, but I was aiming to get the most clamping room I could) Place the castor wheel on the Base and start screwing the first screw in at a slight angle, go 2 or 3 turns (just enough to be sure it's not going to fall out) then move to the diagonally opposite corner and start screwing that one in on an angle. Repeat for the other 2 screws before tightening them all down.

With this file you will be able to print Wheeler with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Wheeler.