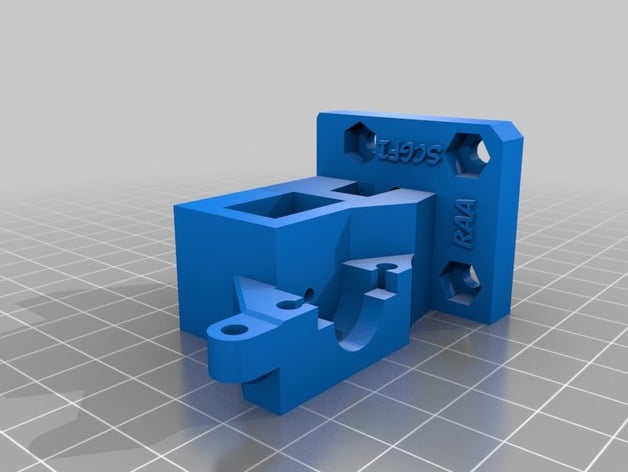

Wilson II hotend mount for Bowden extruder

thingiverse

This is a redesigned hot end mount based on the original Wilson II design files from https://github.com/mjrice/Wilson2 . The goal was to change the original hot end mount to use a Bowden extruder, and reduce the detail and mass of the mount to simplify printing while increasing strength. Overview I have been trying to improve print quality of my Wilson II so I'm attempting to replace the direct-drive extruder mounted just above the hot end with a Bowden extruder. The main goal is to move the extruder motor to the frame and off the print head mount. Reducing the energy needed to move the print head - and importantly, the energy needed to stop it once it's in motion - should reduce backlash and 'ghosting' on prints and allow for faster printing; that's the theory anyway. Starting with the original Wilson II hot end mount design files, I removed as much unnecessary detail as I could while adding additional material around the filament guide to give the downstream push-fit connector of the Bowden extruder more support. Sketchup is not really appropriate for mechanical design but I didn't have a lot of choice since the orginal files were in Sketchup. It was sort of like doing CAD with a broom and the design is far from optimal. There are issues when converting the model to an STL file and to a tool path; an imperceptible amount of 'debris' on the bottom surface of the model causes Cura to render a few small 'islands' around the nut holes before filling in the main bottom layer which leads to poor print adhesion. This was solved by telling Cura to sink the print 0.5 mm into the print bed which led to a solid bond to the print bed. You will probably need to do the same so review the model before printing! Depending on how sloppy your printer is, you may have to drill out some of the holes. The model tolerances are a bit too high for my comfort, but I don't have enough patience to try to get Sketchup to do detail work without breaking everything. I used Tech2C's remix of the Compact Bowden Extruder http://www.thingiverse.com/thing:767951 for the motor mount, though it needs some work to attach it to the 8020 frame of the Wilson II. Some drilling is necessary to expand the filament inlet on top of the to accept the threaded push-fit connector for the PTFE tube; bore this out to match your specific fitting. At the time of posting this, I'm in the middle of grinding down bits of the mount so the hot end fit is not so snug. This is my first design, and while it's derivative and simplistic, it seems workable. I invite you to remix and extend this model; please let me know if you can make it work for you or if you have any improvements you'd like to share

With this file you will be able to print Wilson II hotend mount for Bowden extruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Wilson II hotend mount for Bowden extruder.