YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER

thingiverse

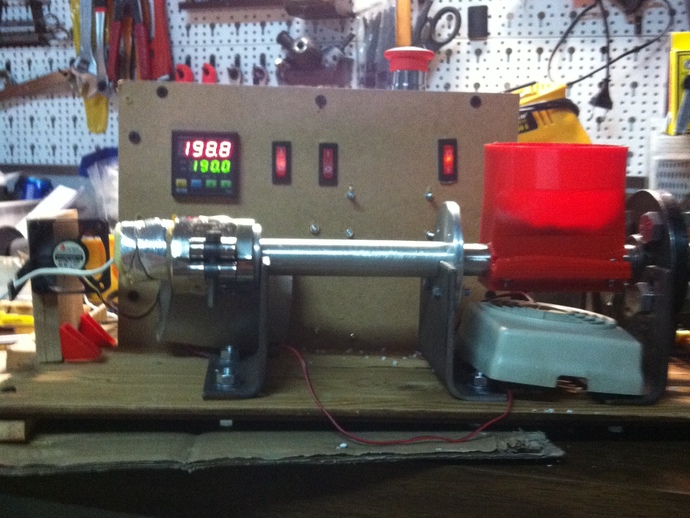

PLEASE CHECK YALFE 3!http://www.thingiverse.com/thing:951240 ! PLEASE LOOK FOR YALFE V2!http://www.thingiverse.com/thing:212894 This is my derivative from Mr Lyman's filament extruder enriched with some of Bottleworks' ideas. UPDATE : -REAR PHOTOS ADDED FOR ASSEMBLY GUIDANCE PURPOSES -FRONT PHOTO REPLACED WITH CURRENT VERSION -TEST PRINT OF EXTRUDED ABS ADDED. PROJECT RESULTS: EVERYTHING IS WORKING PERFECT, I FINALLY MANAGED TO EXTRUDE FILAMENT. TEST PRINTS (CHECK PHOTOS) SHOWED THAT HOME EXTRUDED ABS FILAMENT CAN BE USED FOR 3D PRINTING. In 'instructions' section, i also explain some serious issues i confronted and how i solved them. Instructions Better see Lyman filament extruder v2 http://www.thingiverse.com/thing:34653 and bottleworks derivative http://www.thingiverse.com/thing:32667 The file contains the drawing for the Aluminium part. I extrude 3,00mm ~ 2,8mm filament. Nozzle hole is 2,5mm. What i added, was to put an old monitor cooling fan (something i did not use at all for 10 years now - a good friend gave it to me). It cools the hopper. I did not have to put any heat insulator as Lyman did. Also i put a switch for the nozzle fan. Almost all the parts are from Lyman's BOM. My preliminary extrudes showed that i have to heat ABS first, in order to dry it(80 C for 1 hour). ABS absorbs moisture and makes blobs and pops when extruded untreated. Switches : (right to left) -Main switch -Emergency stop -Motor switch -Temp switch -Nozzle fan switch (the little black dot upper left from temp switch) The hopper cooler fan is always on Rear view photos will follow issues. I have some issues with ABS treatment (as mentioned above). On route, next time i will try to dry some before extrusion.UPDATE although i heated the granules for 1 1/2 hours at 80 C, the filament quality sucks... the filament surface is rough due to pops of stinky fumes from inside the plastic.. i guess that my abs suck... i will give it a final heat for 3 hours (i have about 1/2 kilos it is a pity to through it away). New tests showed that my ABS is MORE than cr@ppy... However, nice sculptures can be created .... see thing: http://www.thingiverse.com/thing:93709 This turn of things is a good lesson for us not to underestimate raw materials.UPDATE The problem was not the moisture, but the cooling air from the monitor ventilator. It seems that the blown air was interfering strongly with the heater section making core temp unstable. I moved the cooler underneath the hopper. Problem solved. Hopper is cool. While extruding, temp drops, causing the plastic to get hard again, and stop extruding... this is a major problem.. i think it is my fault because i did not wait enough (1/2 hours) as Lyman pointed out, for the PID to set itself... i will try to be more patient next time .... problem solved, i also moved the temp sensor near the nozzle Another major issue is the STINK of molten plastic. i have an idea of a fume suction system, i have already the active carbon and the material to enclose it. i need to find a motor, a flexible tube, and a decent design... i am open to to suggestions... i believe that the stink comes from the moisture that is trapped inside the plastic. this causes all the quality problems (see above) i think with the right quality with no moisture the stink problem will be eliminated or at least will be controllable.UPDATE The stink comes from the BOILED plastic due to temp core instability caused by the pipe cooler. Problem solved, see above. GENERAL RULES OF THUMB FOR EXTRUDING 1 try to extrude at low temps. 2 the right plastic viscosity for extruding is that the plastic feels like 'play doh' or 'blue tack' . It must be a little bit hard. This can be controlled by adjusting core temp, extrusion velocity and nozzle cooler proximity. 3 There is not just one extrusion temp because the temp probe is not positioned at the same spot due to different extruder designs. Experimentation is required. Start at 190 C and test extrusion. if plastic comes out easily, try lower temp by 2 C.If not, raise temp by 5 C 4 If you work with plastic that is long time out of the bag, you need to dry it. Try 80C for 1~2 hours, using oven with hot AIR. the granule height layer should be low. Prefer a screen instead of a dish to help air flow through granules. I haven' tested microwave oven, but if you do, try less that a minute heating time. Materials The main pipe is custom made from Aluminium. (thnx to Aris) The sprocket is a standard 30 teeth 1/2 inch, machined with a lathe to reduce weight , and make a hexagon hole for the auger bit.(thnks to Savvas) The auger bit i used is a Milwaukee (or AEG) @16mm with hexagon end shaft The heating element is custom made, 250W, 220V. I used a lot the L-bracket by Azdle http://www.thingiverse.com/thing:2226

With this file you will be able to print YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER.