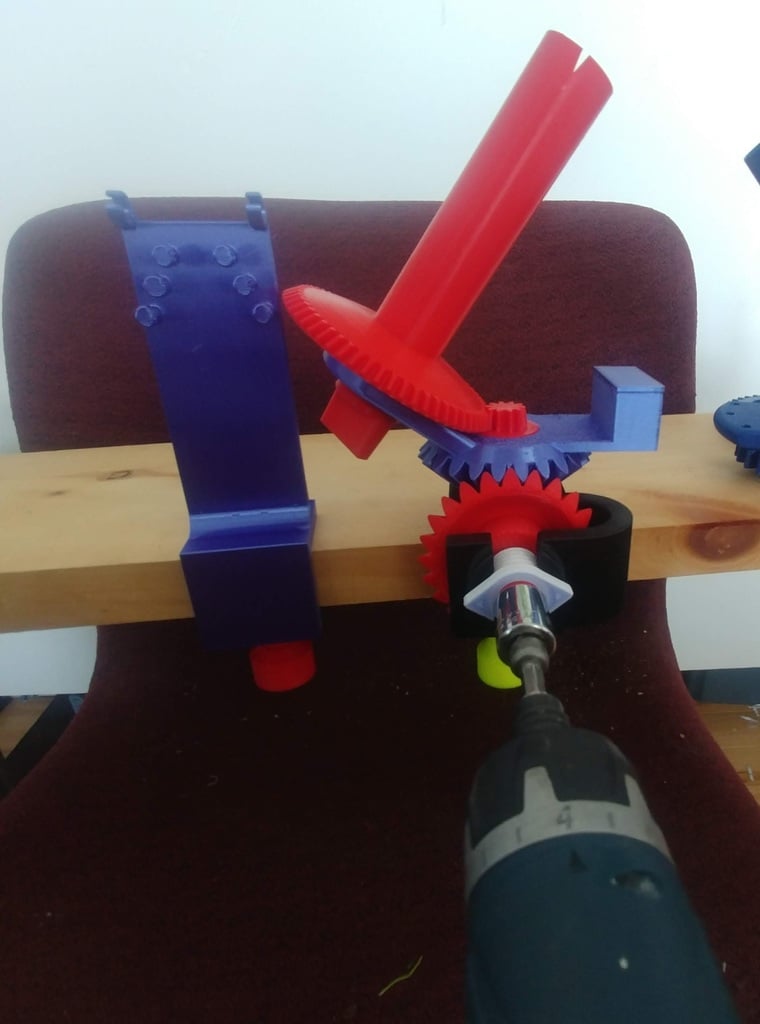

Yarn/Wool Winder All printed power tool driven

thingiverse

Yarn/Wool Winder - 3D Printed - Power Tool Driven March 14 Added additional versions of the screws as original versions were too tight for some printers. "X1" versions have more clearance on the screws so should screw in more easily that the original ones. The "X2" have even more clearance. If the screws are too loose they will unscrew during operation so you may have to check this out when you first operate the wool winder. Feb 7, 2012 - Added files in STL format as some people could not use the AMF format. Files are the same you need one or the other not both. AMF files are in the position I printed them. STL format will have to be positioned for printing. Jan 24, 2021 - Updated main body to increase strength of clamp This design only uses printed parts, no additional screws or bearings are required. To do this I have used large printed screws and threads. The all printed Yarn Winder runs surprisingly well and I have seen no wear at all after the equivalent of 50 skeins of wool. The yarn winder is all printed, clamps to a desk or counter and is powered by a cordless Drill/Driver using a 9/16 inch or 14 mm socket. Demos and assembly video on Youtube. https://youtu.be/086WCk0imxk Parts and printing suggestions (See diagram) I used PLA for all parts and increased the wall thickness from 1.2 mm to 3.6 mm to get the strength I needed. Main Body - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher. Gear 1 - Standard wall thickness 1.2 mm Gear 2 - Standard wall thickness 1.2 mm Center Gear - Wall thickness 3.6 mm. Supports - touching build plate Large Gear - Standard wall thickness 1.2 mm - no supports Large Gear Screw - Wall thickness 3.6 mm. Supports - touching build plate G-Clamp Screw - Wall thickness 3.6 mm. Supports - none Center gear Tool - Standard wall thickness 1.2 mm no supports I have provided the AMF/STL files in the position I printed the parts. Optional Gear 2 Lid. Standard wall thickness 1.2 mm No supports Counter Weights Yarn Guide/Tension - Wall thickness 3.6 mm. Support everywhere. 3 times the normal thickness to add strength for the G Clamp and screw thread. I used 20% infill everywhere but you can go higher. The Yarn Guide/Tension uses the same G-Clamp screw as the Winder. Assembly instructions in the attached document

With this file you will be able to print Yarn/Wool Winder All printed power tool driven with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Yarn/Wool Winder All printed power tool driven.