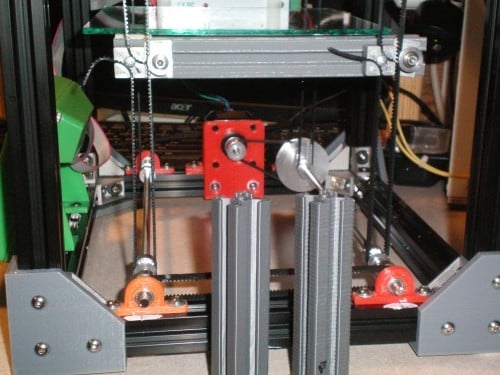

Z-axis Belt Drive

thingiverse

12/28/20 Update: A "Z" travel guide added to bed and idler pulleys removed from the bed. Improved vibration control. The guide uses 1/4" rod. The two printed parts, stl and scad, included. Needs 2020 extrusion and corners. Print bushing at 100% to prevent pinching rod. Picture included showing changes. No lead screw core xy printer. My experiment: Having all belt drives, the bed supported by belts. I built this core xy Mini by MacGyver leaving out the Z-axis parts. I stayed true to the structure of his Mini, but changed some parts, using ones that I already had. The slotted motor mounting is great for belt tension. I am using this printer now and it works as expected, however, reducing speed, like travel, is a big help reducing vibration, which I find is the main problem. My plan was to create a Z-axis drive using a belt system and if it failed, add the cantilever as a bed support, still using belts. I found the bed is subject to the vibration of the xy movement because of the flexible belts, and like a slingshot if the nozzle contacts the part during printing. The first improvement was idlers at the GT2 attachment to the bed. There is a before and after picture of printed 2020 extrusion showing effect. The idlers support the long belt length and steady the bed in the front to back direction. The second is the plywood base with M5 screws tapped into the vertical 2020 frame corners. This dampened the vibrations in the printer frame. The bed still needs improvement for vibration dampening(ringing at the least). A picture of the part cooling duct shows this ringing. The bed is made from printed 2020 extrusion making it easy to adjust belt position with v slot on the sides. The bed has 4 inside corner brackets and also Superglue holding it together. (190x180mm.). The plate is aluminum and unheated. There are 4 GT2 belts with idler pulleys at the top. The pulleys are turning on M5 cap screws in the top frame. On the bottom are two M5 rods running on pillow block bearings. These front and back rods are synchronized by two 20T pulleys and approximately 300mm GT2 belt loop, and rods are approximately 135mm apart(c-c). The 4 pulleys driving the GT2 bed loops are 16T. The Z stepper motor has 20T pulley and the other pulley is 60T.( 300steps/unit in Marlin firmware). The limits right now are 150,130,150mm. Adjusting the bed is done by loosening a pulley, adjusting and re-tightening. Using a level. I added one .stl for the part cooler which was contacting the idler hardware mounted to the top frame. Narrowed to 40mm. https://www.youtube.com/watch?v=cb8U4UkiPFE

With this file you will be able to print Z-axis Belt Drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Z-axis Belt Drive.