Z endstop for X Gantry level and synchronization (Ender 3)

thingiverse

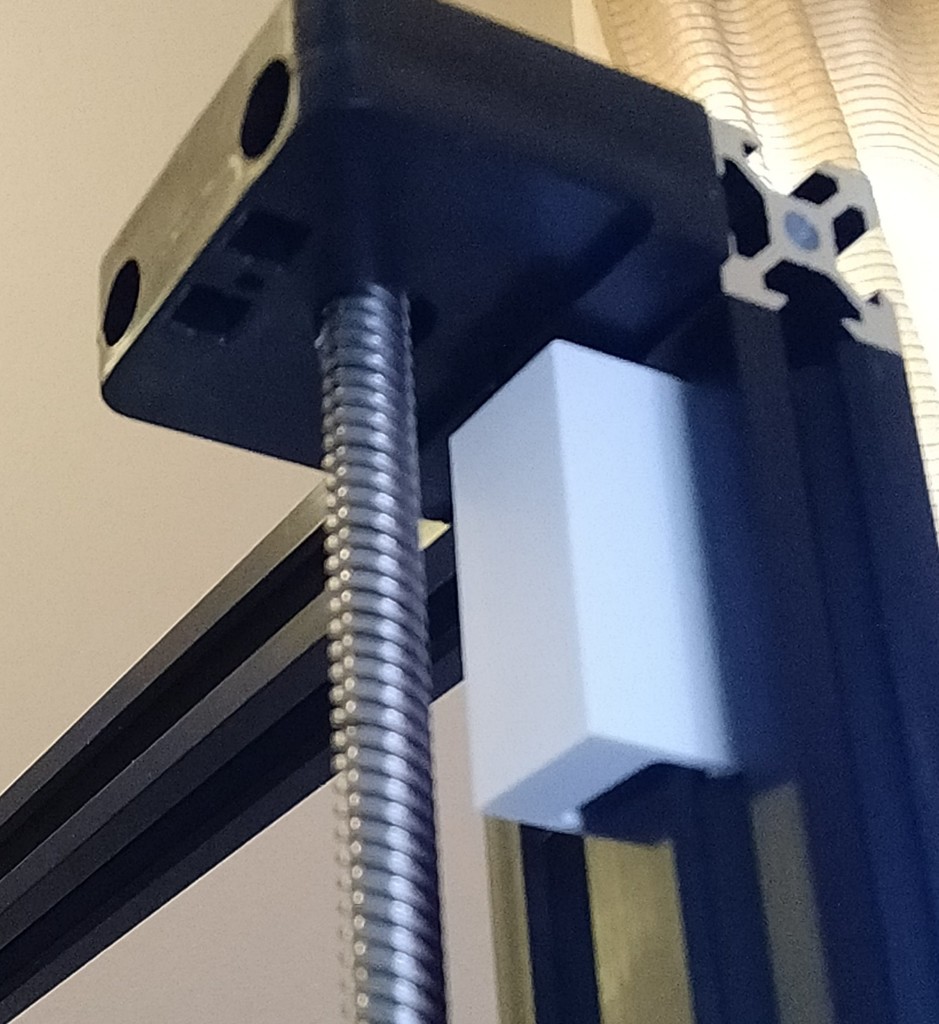

This is a remix for the Display Ribbon Cable Clip by gn-jr https://www.thingiverse.com/thing:2880021 Designed for an Ender 3 Pro with dual z axis steppers I needed something to even up the X Gantry after installing a dual Z stepper kit in order to synchronize the motors (this might work on the single motor dual z setup as well, but I don't have one to test). The idea is to use 1 of these clips on either side to halt the z axis when you send commands to raise the x gantry to the top of travel. This should fit between 2 V rail grooves in front of the z axis screw at the top of the travel on the 2040 rail. Some minor trimming may be required to clear the assorted bracketry or screws so it touches the bracket squarely. I did not need to trim on my setup. You might need to remove the top cross brace but it's possible to snap them into place without removing it. If the x gantry is not even, the stepper will hit the stop on the high side while the low side continues until it hits the stop on the other side. You will need to measure and adjust the scaling/length for your printer because they are not even from side to side due to the extruder on the left side. I used 26mm on the left (extruder side) and 38mm on the right side but you will need to verify how it works on your setup to achieve an acceptable level. I got down to a .5mm difference and called it a day. This means you will need to resize the print to fit your application. Print the left one at 26mm and the right one at 38mm and see how the distance of the x gantry to the bed works out. You should only need to run the z motor up to the top once in a while so no need to add it to your start code. if you have that much variance in your x gantry level from print to print where you think you need to add something to your start code to synchronize the z steppers, you probably have bigger issues. I've upped the motor current to 650 from 550 (steppers are wired in parallel on my kit) and left stealth chop on because turning it off made the z steppers way too noisy for my silent board.

With this file you will be able to print Z endstop for X Gantry level and synchronization (Ender 3) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Z endstop for X Gantry level and synchronization (Ender 3).