Z-Probe for CNC

thingiverse

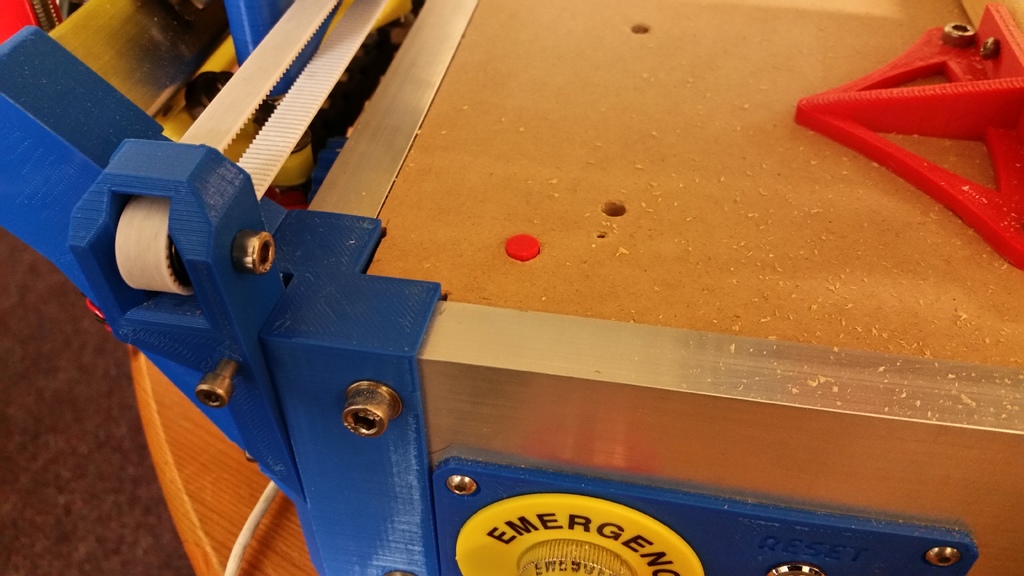

It appears that you've provided a step-by-step guide on how to set up and test a Z-probe (a type of sensor used in CNC machines) with a Maker-FR shield connected to an Arduino Mega. The steps cover everything from plugging in the microswitch to Repetier firmware configuration, manual testing, and finally calibrating the probe's trigger height. Here are some key points: **Step-by-Step Instructions:** 1. **Connect the Microswitch**: Connect the microswitch to the chosen pins on your controller. 2. **Check Electronics**: Plug in your USB and PC, and run G-code M119 with the switch pressed/unpressed to ensure the controller can sense it reliably. 3. **Reassemble Baseboard**: Reassemble the baseboard, pop the pusher cylinder into the hole, and make sure it moves smoothly and clicks the switch. 4. **Check Firmware**: In Repetier, check settings such as Z_PROBE_ON_HIGH, Z_PROBE_PIN, and Z_PROBE_SPEED. 5. **Manual Test**: Power up the machine, home the head, and try a single point Z-probe operation (G30) with the probe pressed manually to ensure it works correctly. **Calibrating the Probe's Trigger Height:** 6. **Trigger Point Height**: Check your Firmware. In Repetier, we worried about (in configuration.h): * `#define Z_PROBE_SWITCHING_DISTANCE 1.0` - this makes it take the average a set of 5 probes in quick succession, bouncing up 1mm between probes. * `#define Z_PROBE_REPETITIONS 5` 7. **Trim Trigger-Point Height**: Now you know the trigger height, you can trim out the trigger-point height in the Repetier firmware: * `#define Z_PROBE_HEIGHT 0.20` **Testing with a Real Bit:** 8. Try it with a real bit. We clamped some 18mm pine on the bed, and tried `G30 H0 R-18` (note the minus sign!), which sets the measured zero point to Z=-18, so Z0 is now 18mm above the board. **Final Steps:** 9. Open a beer. 10. Add a button command to Repetier Host on the PC to run: * `G28` * `G30 H0 R-18` * `G0 X200 Y300 F5000` * `G92 X0 Y0` * `G0 Z5 F500`

With this file you will be able to print Z-Probe for CNC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Z-Probe for CNC.