anet a8 nylon 3d models

36943 3d models found related to anet a8 nylon.

thingiverse

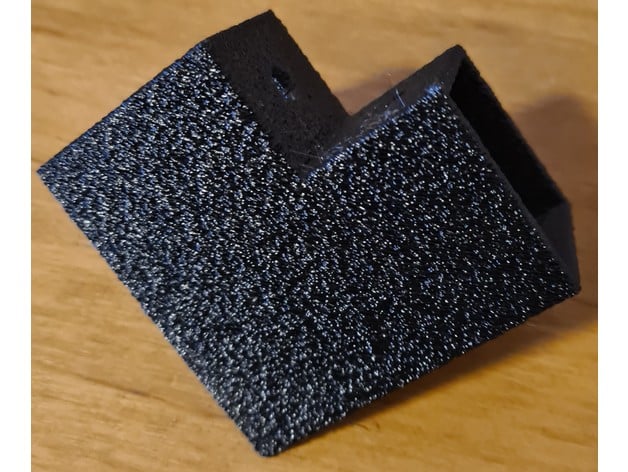

So, I uploaded a revised version with thicker walls and recommend printing in ABS or Nylon or isolating the aluminum plate/wood with Kapton tape to prevent heat from moving upwards. The default design should be sufficient, but ensure that the main...

prusaprinters

If your printer can handle nylon or polycarbonate, those will work great as well, otherwise this is the recommended order of preference:ASA: Top of the list for automotive needs due to its high UV and thermal resistance.ABS: ASA is a better fit...

prusaprinters

Nylon is best but others work well.Instructions | Print at 0.30mm layer thickness. The first layer default of 0.20mm is fine. Add print pauses before 13.7mm (layer 46) and 185.6mm (layer 619) to insert magnets. </p><p><strong>Magnet Latch |...

prusaprinters

Also, be sure to set your "Retract amount before wipe" to 0% if you are using PrusaSlicer. You can find all of the 3D printed parts you will need here: You will also need: ► (QTY 5) M3 x 10mm socket head cap screws ► (QTY 5) M3...

cults3d

boat bollard mooring duck bv03 for 3d print and cnc Heavy-duty and high-strength boat Yachat deck mooring open top flat base clip Easy installation, durability, and corrosion resistance -Multiple applications such as Sea Boat, trucks, van, caravan,...

prusaprinters

but don't use 3.7v batteries to instead, they will kill your camera.you may need a charger as well Litelong 14500 10440 3.2V AA AAA LiFePO4 Rechargeable Batteries Charger New...

thingiverse

Parts and Specifications: Bottom Unit Printed Parts GWS Servo Plate GWS Servo Deck Plate Bearing Plate Bearing Deck Plate Top Unit Printed Parts Tall Turret Short Turret Std Mobius Mount Std Dual Camera Mount Std Misc Camera Mount Over-Under Camera...

prusaprinters

Be sure they are straight. Print instructionsRafts: No Supports: Yes Resolution: 0.2 Infill: 10 to 15% Parts you need for the build: Brass inserts 76 pieces...

thingiverse

The design fits closely to the nozzle of the Revo which means you absolutely must print the part cooler out of a material that has a high heat deflection such as Carbon Fiber reinforced Nylon 6 or Polycarbonate. No, you cannot print the cooler out of...

thingiverse

- some light, but air-tight fabric, I used kite fabric, 20d or 40d waterproof ripstop nylon. - the printed files from this thing, and things 6022070, and 5996966 To assemble: - print all the STLs. This took ~a day of printing. - sew a tube...

cults3d

Nylon Zip Ties Anti-Skid Pads (Optional) How To Print & Assemble: Clearance Test: (Recommended) Print the small ‘Outlet Size Test.stl’ (bottom flat side down, no supports) to test the fit between your print and pneumatic coupler. If it's too tight to...

thingiverse

Print in something rigid such as Nylon or PETG, TPU will not work! ... Use brass threaded inserts too to make sure you have a secure fit  Other needed parts =============== * 5x M2 Clinch nuts * 5x M2 arm...

prusaprinters

Otherwise the shaft will not fit.Put the nylon washer between the bearing and printed pulley.Fully push the shaft up to the end - take it back very slightly so it won't touch the motor.Tighten the screw of the printed pulley through the hole in the...

prusaprinters

Used bearings 624 (ZZ) and M4 bolts with nylon nut.https://youtu.be/blGmY5eO09Y Jednoducha tocici se plosina nejen na fotografovani.K pohonu je pouzit DC 5V Stepper Motor 28BYJ-48 + ULN2003 Stepper Motor Driver Module pro Arduino (or...

prusaprinters

Assemble the idler pulley hardware. insert the 2 heat set inserts into the baseplate Bolt one of the 1/4" threaded spacers to the center-ish hole using one of the 6-32 bolts in the recess (after cleaning the hole) bolt the base plate to the idler...

prusaprinters

Otherwise the shaft will not fit.Put the nylon washer between the bearing and printed pulley.Fully push the shaft up to the end - take it back very slightly so it won't touch the motor.Tighten the screw of the printed pulley through the hole in the...

prusaprinters

The original XT-60 connectors from HobbyKing are high quality nylon and should survive this process without a problem.Because the pins of the connector will protrude out of the bottom of the panel mount once installed, be sure not to just stand the...

prusaprinters

...Insert the M5 nylon lock nut on top of this. Note: The MK8 hobbed gear has very shallow teeth and not very sharp to avoid deforming the filament. In my case I have to apply a considerate amount of force to the tension sprint to avoid filament slip.

prusaprinters

(recommended)Desiccant, to keep the inside dry.Nylon Zip TiesAnti-Skid Pads (Optional)How To Print & Assemble: Clearance Test: (Recommended) Print the small ‘Outlet Size Test.stl’ (bottom flat side down, no supports) to test the fit between your...

thingiverse

If you can print nylon, that's really the best for durability against shovels and such. The original Dri-Splices are molded in nylon. However I did some research and found out that really any filament will work here, even PLA won't biodegrade when...

thingiverse

Some like nylon where a little longer is needed to grab the nylon. Others like using blue locktite where a bit shorter can work just as well. I am using blue locktite in my demo. - 2mm steel rods - these are not necessary but do add a great deal of...

thingiverse

------------------------------------------------ BUILDING -------------------------------------------------------- Hand: To build the hand, simply use pieces of flexible nylon fed through the fingers and tied at the back of the hand. Then, feed...

prusaprinters

If your nylon nut is thicker than what I recommend or have shown as the actual thickness, then you will need to file down to the specified thickness. If less than the specified thickness, then you might try placing a piece of paper below the nut to...

cults3d

So I recommend you not only to use the following materials and print settings, but to test your finished grenades in a safe environment first: I recommend for the body of the grenade PLA+ or Meta PLA, for those who want it extremely robust nylon. for...

prusaprinters

Of course, you don't have to use these exact components, but this is how I purchased my parts for this kit.The list of the hardware used is as follows:Tezuo 21A Micro Long Arm Roller...

thingiverse

Basic Case4x M3x6mm heat-set inserts Amazon4x M3x8mm machine screw Amazon4x M3 washer Amazon3x M2.5x4.5mm heat-set inserts Amazon3x M2.5x8mm standoffs Amazon3x M2.5x3mm machine screws (I used the ones that come with the RAK19003, but any that are 3mm...

thingiverse

I recommend using M2x20mm stainless steel socket cap screws like...

thingiverse

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

prusaprinters

To be sure use a “nylon-insert lock nut” or an extra nut for locking or loctite. If a double nut get loose it can lock itself against the wall or bearing, wich will end up in a crash. So be sure they are tight or don't use them.The two axis must run...

thingiverse

Rear XY motor plates: preferably metal, but you can also print with a stiff material, preferably PC-CF or PETG-CF, avoid nylon as creep might be a concern. Supports on build plate required for bearing cavity XY joiner plates: print a dummy part...