dual axis joystick 3d models

120263 3d models found related to dual axis joystick.

prusaprinters

Want to engage the ratchet mechanism in the opposite direction you’re using it in that moment, well, flip the orientation of the R.E.P Ratchet around by 180 degrees along its longest axis, and you can use the tool in the opposite direction. The...

prusaprinters

The issue here is that the linear bearings or frustratingly intolerant of even the slightest bit of off-axis with the rods. To provide enough wiggle to make the bearings happy, I tweaked the rods as noted above. We're talking about 0.10mm taken off...

thingiverse

This modification requires an additional axis (i.e. stepper) to drive the linear actuator which in turn opens and closes the jaws of the inline cutter. How to add another stepper to your machine is beyond the scope of this documentation. Please...

thingiverse

At the base of the Z axis drive behind the vat are small openings that lead into the base. When the electronics cooling fans are on, a venturi effect is created dragging a small amount of the fumes from inside the UV cover through those openings and...

prusaprinters

Also for printability, many values of z-axis (height) parameters are measured in layers, not millimeters or inches. Remember to set the <strong>slicer layer heights at the same values</strong> of the swatch; you can use different values for the first...

thingiverse

Thread the assembled carriage holders into the rails and rods of the Z-axis.  <span></span> ...

thingiverse

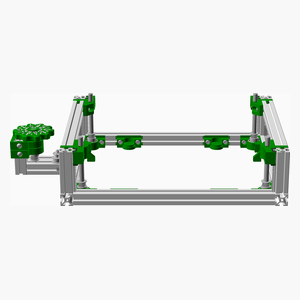

The Z axis moves very slowly, so speed is not the priority - precision and resolution are. The V-Core 3 uses TR8X4mm lead screws instead of the TR8x8mm used in previous machines, effectively halving the pitch of the lead screw - this means that...

thingiverse

The Z axis moves very slowly, so speed is not the priority - precision and resolution are. The V-Core 3 uses TR8X4mm lead screws instead of the TR8x8mm used in previous machines, effectively halving the pitch of the lead screw - this means that...

thingiverse

Icarus is using the new high quality and increasingly popular lightweight Orbiter 1.5 dual gear extruder and Dragon or Mosquito hotend. The gears in the extruder are made by Phaetus, the maker of the Dragon hotend (also made by Trianglelab). The...

prusaprinters

may be siginificant for proper function.1: Strongbox - Main body parts_0.2mm_PLA_MK3S_10h14m.gcode2: Strongbox - Lid assembly (Harry Potter)_0.2mm_PLA_MK3S_2h40m.gcode3: Strongbox - Ring assembly top spacers_0.2mm_PLA_MK3S_5h10m.gcode4: Strongbox -...

thingiverse

Icarus is using the new high quality and increasingly popular lightweight Sherpa Mini R1 dual gear extruder and Dragon or Mosquito hotend. The extruder has a 50:10 gear ratio, is ready to print flexible filament directly and weighs only around 120 g...

prusaprinters

I present to you, what is likely one of the only mechanically working 3d-printed Prop Revolvers available, especially for free!Go here to see it in Operation: https://i.imgur.com/DBUVUkF.gifvIt is quite well balanced, see here:...

prusaprinters

It's probably not the lightest effector ever, but I doubt there's anything out there as light as this with dual cooling fans. Cooling: Holy cow, this might be the best part. With 19mm cPAP tubing to provide remote cooling from some more powerful...

thingiverse

Icarus is using the new high quality and increasingly popular lightweight Sherpa Mini R1 dual gear extruder and Dragon or Mosquito hotend. The extruder has a 50:10 gear ratio, is ready to print flexible filament directly and weighs only around 120 g...

prusaprinters

https://youtu.be/EvG4uqx-Oos) Maintenance:Since the printer come with a bowden setup equipped with a dual gear extruder (creates a hell of grip), an original Capricorn PTFE tube and a regular hotend (where the PFTE tube is directly...

thingiverse

www(thingiverse.com/apps/customizer/run?thing_id=507810) Instructions Using these options: - Use mouse ears: no (use_mouse_ears = 0) - Customize back camera height: 20 units (custom_back_camera_y_size = 20) - Port corner radius on bottom side: 8...

prusaprinters

You can probably scale the z axis to get the height you need. I printed with a 1mm brim to help them stick to the bed, then used a hobby knife to cut the brim off. I used PETG, but I suspect anything would work well enough.</p><p><strong>For the...

thingiverse

I decided I wanted heat exhaust holes on the tops so I made a cut and then discovered I couldn't use linear pattern along a line - just an axis - so the ones on the top point wouldn't work. This forced me to do some Googling and I discovered I could...

thingiverse

So multi-axis is something that has had some next shiny object attention to it and now, how about multi-stroker capability. This is more a future thing for custom scripts, maybe custom software to control 2 handys simultaneously and catering for left...

thingiverse

You may think your printer's X and Y axis are a perfect 90 degrees but have you ever actually tested and verified it over long distance? Two 30mm parts fitting together is a lot different than two parts ten times that size fitting together. I...

cults3d

you do not need a pullup for z_min -#define Z_MIN_ENDSTOP_INVERTING true (provided you use the LED on with VR2 method) -#define X_PROBE_OFFSET_FROM_EXTRUDER 0 // X offset: -left +right [of the nozzle] -#define Y_PROBE_OFFSET_FROM_EXTRUDER 0 // Y...

thingiverse

My some other things: <img src="http://things.ruvim.info/img/Disc-Sander-Duo.-D50mm,-D75mm.jpg" alt="Disc Sander Duo. D50mm, D75mm" title="Disc Sander Duo. D50mm, D75mm"></a> <a...

prusaprinters

total cost blew out here, 20x35mm, 20x30mm and 50 4mm nuts was $25, I am starting to see where that $20,000 pricetag for a commercial unit comes from. (deleted: and the idler bearings are currently cheap 4x13x5 versions, hence flange parts to hold...

thingiverse

Next, place the MainTrigger into the small slot between the two halves and insert the M3x16 screw through both halves and the trigger such that the trigger can freely rotate around the screw axis. Finally, double wrap the very small rubber band...

prusaprinters

It isn't necessary to use a layer height finer than 0.2 mm, because none of the pieces have much detail along the z axis. Supports are not necessary, they have been modeled in where they are needed. I printed my calendar in PLA, but it should print...

cults3d

If your print volume is smaller, try to rotate them by the Z axis. They should fit a 200x200 mm buildplate when rotated so they are placed diagonally on the build plate. +++ Print settings +++ The relevant recommended print settings: 0.2mm layer...

thingiverse

kürzen)26 Muttern M2SekundenkleberSteuerplatine (siehe ZIP-File "Elektronik")winding machineThis project describes the construction of a winding machine that can be used for winding magnetic coils and inductors.Update:ATTENTION: THE LIMIT SWITCHES...

thingiverse

Я также сделала два вида крышек, которые позволяют перевозить органайзеры и защищают содержимое от пыли.Parts links below: Handy dispenser 200ml Automatic Toothpaste Dispenser Bathroom Accessories Toothpaste Dispenser Multi-functional Creative...

thingiverse

My some other things: <img src="http://things.ruvim.info/img/Disc-Sander-Duo.-D50mm,-D75mm.jpg" alt="Disc Sander Duo. D50mm, D75mm" title="Disc Sander Duo. D50mm, D75mm"></a> <a...

thingiverse

An unlock button is also provided to unlock the X and Y axis (it allows to freely move the hotend along the bed) - Auto bed leveling menu: it requires that feature is also enabled in Marlin firwmare (e.g. Waggster fw) - Improved Z Offset menu. Now...