D Separate Line Calciner, Kiln, 3d models

461601 3d models found related to D Separate Line Calciner, Kiln,.

thingiverse

DO NOT print the mounts 'bottom down' for the layer lines will become a weakpoint in your base and you can lose the gopro. Highly recommend washers on all mounts, RDQ has nice countersunk ones. I try not to add extra things I dont need to my quads,...

thingiverse

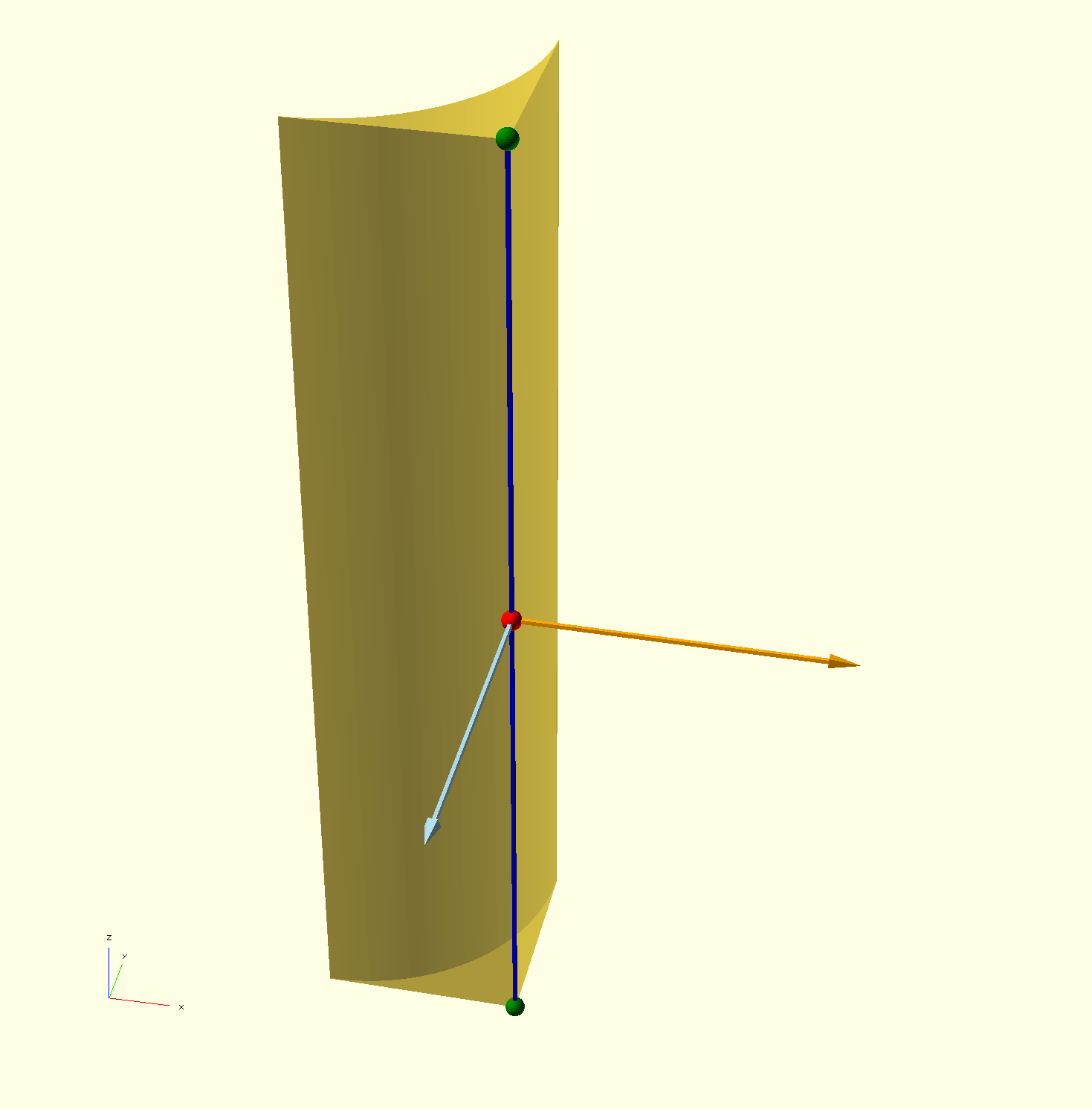

In the above image: - The blue line is the edge (corner) that you want to smooth, where the two faces meet. - The <span...

prusaprinters

When all 4 pairs are in then with some wiggling you should be able to get everything to line up with the top piece and click the pillars into that one as well. If you would like to keep up to date with my latest work, follow me on...

prusaprinters

Others use 2 line lasers to form a cross at the spindle position, these are large permanent devices added to your spindle mount but are always there, just a flick of a switch away from seeing the spindle's position.My other thing, Z-Axis Pointer is a...

prusaprinters

Turn it over and add glue in the square indicated, line up Driver knob and press it into the glue. The magnet on the bottom side of the Driver knob is optional depending on how you intend to use the system</strong></p><p><strong>Once the glue holding...

prusaprinters

The washers should line up as shown in the picture. Put the motor in position and turn each washer 90 degrees. The motor should run in the groove, but it should not come loose. If your motor does not have cables soldered in its terminals you can do...

prusaprinters

As it gets closer to the joiner piece line it up with the faces of the top plate and screw them on together. Screw it only finger tight initially. Now take a 17mm spanner and hold the nut on the bottom of the basket and gently tighten the top plate...

cults3d

Team Members: Khopesh Warrior Linemen: Not the fastest, not the strongest, but a good all-rounder, the Khopesh Warrior Lineman will take his trusty Karumbit Knuckles straight to the face of any player sat opposite him on the line of scrimmage – no...

![PaScn3D Mk.0 - 3D Scanner [PrusaPrinters Contest Edition]](/img/img-not-found.svg)

prusaprinters

If you have a printer, then you have such electronics! PaScn3D connection to Prusa 3D printer in a minute (tested!) – dedicated mounting brackets, components adapted to the dimensions of the device Modularity – adaptation to other printers without...

prusaprinters

Record the sequence on the line below. mRNA Sequence: Record the number on the back of the mRNA: On the Ribosome The A, P, and E sites are labeled. In the space below, describe what happens at each stage: Initiation: Slide your mRNA into the small...

prusaprinters

If you intend to use higher power bulbs, it is recommended to use PETG or ABS for both the electronics case and the electronics cover. How to prepare the GrowBox for the first plants:Pair the Blitzwolf switch module with your wifi network,...

thingiverse

Unfortunately, I do not have an A & B version of the tilt plate to accommodate any CW/CCW offset from center, so hopefully your servo centers in line with the groove in the plate. This time, remove the servo arm from its seat before installing the...

cults3d

In this case, you won't need the "line-changer actuator" in the car but you will need electronics under each lane-changer track part, specially the "sensors" and the "actuator". There is a very good thing about the InfraRed lane-changers... You can...

prusaprinters

While not quite as simple as using a loaded pickguard with everything already soldered together, if you can follow lines, you can wire this up. I used this wiring diagram to guide me through and it is a match for the parts that I used. Just be...

thingiverse

Notes on my accelerated printing settings: =========================================== I have my printer's stock hardware (with 0.4 nozzle) using tweaked slicer settings that not only emulate a 0.6 nozzle, but also increase movement speeds (both...

cults3d

First, move the SliderBolt about halfway along its slide distance such that the pegs coming out of the side are in line with the hole on the ActuatorLeverMount's curved arm. Place the long slot on the BoltActuatorLever over the peg, then align the...

prusaprinters

Even standard white PLA looks good, in an under-stated sort of way.Sanding, using filler to hide the layer lines, resanding, high-fill primer/undercoat, fine sanding, second primer coat, metallic spray paint, very fine sanding, second paint coat,...

prusaprinters

Add washers if the clamp is disassembled/reassembled fairly often. To create stackable clamps for parallel pipes of different sizes, the clamp for the smaller pipe needs to be the same size as the one for the larger pipe so the bolt holes...

prusaprinters

Nibblers can be had for less than 15€ at Aliexpress.(optional) 10 screws or some glue or silicone to make the cyclones stay in place permanently.Building steps:The pictures of this thing are lined up to represent the building steps below.Print the...

thingiverse

This will let Marlin reply with error messages, that will be displayed on both Octoprint and TFT display, such as: * Line Number is Not Last Line Number +1 Last Line 1686. In order to avoid the problem, when printing with Octoprint/Pronterface...

thingiverse

The extra side mounted blower fan is spliced into the power lines of the original side mounted blower fan. There is a cutout on each side of the new housing that will retain the wires for the side mounted fans. I recommend using some epoxy on the...

prusaprinters

Rotate the head further until the flat sides line up with the three screw holes:2. Attach the 'top-connector' to the ‘top’ by using 3 M3 screws:</p><figure class="image image_resized" style="width:46.14%;"><img...

prusaprinters

The "cylinder" is designed to be replaced if other sizes are needed, and the STEP files are included which should make this easy to remix or add different drill sizes. The base and fence have marking lines spaced at 10mm intervals on the base and...

prusaprinters

the point of the thread) on either side. Then, update the Expression value in the ConnectDiameter row (the box highlighted yellow below) with this found value.Connector Length - Measure the height (in MM)...

prusaprinters

These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_VENDOR_PRUSA3D\nPRINTER_MODEL_MK3\n printer_settings_id = Original...

thingiverse

If I print 3 wall lines, one string hangs into the gap, but is easy to remove with a small v-shaped knife. You should have a 2nd view on the wheel bearings, they should run soft but I had problems printing a perfect bearing, V16 seems to solve...

thingiverse

Now you connect the bridged L/R and GND from the BT board to line in (IN-L OR IN-R and GND) of the amplifier (if you are using a stereo amplifier, connect to either the left OR right channel). Finally connect the output from the amplifier (L+ and L-...

prusaprinters

The same is true for Pattern Text.Add TextEnable Text and enter what you want under Lid - TextThere are more settings under Lid - Text OptionsIf you want to use a different font per line, you can set this in Lid - Advance Text Options---Logo...

![JGAurora A5 E3D drag knife mount [vinyl cutter]](/img/img-not-found.svg)

prusaprinters

300x300 mm² sticky pads that hold on to the vinyl)20 mm rubber band or the printed spring2x M3x8 hexagon socket head cap screw2x Ruthex RX-M3x5.7 threaded insertsPrint SettingsPrint all models in their provided orientation with 0.4 mm nozzle, 0.2 mm...

prusaprinters

I put a small washer in between the bolt head and the bearing, but this is likely optional Slide the main bondtech drive gear down onto the bolt and line up with the inner filament track. Secure it using the setscrew to the flat spot on the...