axis xyz 3d models

81416 3d models found related to axis xyz.

thingiverse

My some other things: <img src="http://things.ruvim.info/img/Disc-Sander-Duo.-D50mm,-D75mm.jpg" alt="Disc Sander Duo. D50mm, D75mm" title="Disc Sander Duo. D50mm, D75mm"></a> <a...

thingiverse

The switching extruder is built for a Geeetech Prusa i3 pro B printer and its X-axis carriage. Nevertheless, this design can be altered quite quickly to suit any other printer. The extruder is fed with two filaments which can automatically be...

thingiverse

If you are using a printer like a Core X/Y or one that does have a bed that only goes up and down following the Z axis, you should not have this issue and you could print the normal parts all at once. <b><u>4. Assembly</b></u> Regarding assembly...

thingiverse

My some other things: <img src="http://things.ruvim.info/img/Disc-Sander-Duo.-D50mm,-D75mm.jpg" alt="Disc Sander Duo. D50mm, D75mm" title="Disc Sander Duo. D50mm, D75mm"></a> <a...

thingiverse

An unlock button is also provided to unlock the X and Y axis (it allows to freely move the hotend along the bed) * Auto bed leveling menu: it requires that feature is also enabled in Marlin firwmare (e.g. Waggster FW) * Improved Z Offset menu. Now...

thingiverse

Lets look at the example of the Swincar which is an engineering master piece that feaures multiple steering axis per wheel, which all fullfill the general requirement paradigm that avoids bump steering and allows more or less load insensitive stable...

thingiverse

[gcode_macro START_PRINT] default_parameter_BED_TEMP: 60 default_parameter_EXTRUDER_TEMP: 210 gcode: {% set BED_TEMP = params.BED_TEMP|default(60)|float %} {% set EXTRUDER_TEMP = params.EXTRUDER_TEMP|default(190)|float %} # Start bed heating M140...

thingiverse

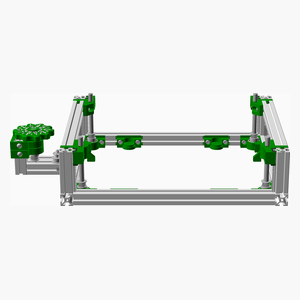

The Z axis moves very slowly, so speed is not the priority - precision and resolution are. The V-Core 3 uses TR8X4mm lead screws instead of the TR8x8mm used in previous machines, effectively halving the pitch of the lead screw - this means that...

prusaprinters

Also for printability, many values of z-axis (height) parameters are measured in layers, not millimeters or inches. Remember to set the <strong>slicer layer heights at the same values</strong> of the swatch; you can use different values for the first...

thingiverse

The Z axis moves very slowly, so speed is not the priority - precision and resolution are. The V-Core 3 uses TR8X4mm lead screws instead of the TR8x8mm used in previous machines, effectively halving the pitch of the lead screw - this means that...

thingiverse

Using that command you *“can specify the kinematics equations for any printer with up to 10 axes for which the movement of each axis is a linear combination of the movements of the individual motors” 1*. This command is placed in the config file and...

prusaprinters

[gcode_macro START_PRINT] default_parameter_BED_TEMP: 60 default_parameter_EXTRUDER_TEMP: 210 gcode: {% set BED_TEMP = params.BED_TEMP|default(60)|float %} {% set EXTRUDER_TEMP = params.EXTRUDER_TEMP|default(190)|float %} # Start bed heating M140...

thingiverse

Thread the assembled carriage holders into the rails and rods of the Z-axis.  <span></span> ...

thingiverse

Sight where my weather station reports to is http://shermluge.xyz/wx This is still very much a work in progress but has been collecting data now since Dec 13 2017. Over 17,000 records. The website is still very rough, I've hard coded everything, even...

prusaprinters

It isn't necessary to use a layer height finer than 0.2 mm, because none of the pieces have much detail along the z axis. Supports are not necessary, they have been modeled in where they are needed. I printed my calendar in PLA, but it should print...

myminifactory

https://www.dropbox.com/s/he8unc0m6j0wk57/Bed%20Handler.rar?dl=0 Cost 1/5Difficulty 1/5Goal : Lubrification of the axis guides, reducing noiseMean : Using a refining base oil with lithium soap thickening, an antioxidant and anti-rust additives...

prusaprinters

Set them all equal to each other.Flat end of the arc is facing towards the center while the ending arc is facing outwards.4.Circular eyesMeasure out from the left side and create a construction line for the horizontal axis the eyes will be on. Find...

prusaprinters

The RP1 potmeter to adjust the trigger sensitivity of the strain gauge remains accessible.When installing the ribbon cable put the extruder cable trough the clamp before the ribbon cable.Completing the installationThe installation is then completed...

prusaprinters

I should snuggly fit with this model: https://www.printables.com/model/123074-ceiling-camera-mount-2-axis.03: Added the grow lights for indoor plants, see pictures. Also added a section describing the little differences. Earth anchor is good to go...

cults3d

Marlin/RRF reference: 1900 steps / mm (rotation_distance = * / * ) # values set for Flex3Drive G5 Flex Extruder rotation_distance: 7.71 # Triangle Lab BMG clone full_steps_per_rotation: 200 # for a 1.8 stepper #gear_ratio: 19:16 # values set for...

thingiverse

www(thingiverse.com/apps/customizer/run?thing_id=507810) Instructions Using these options: - Use mouse ears: no (use_mouse_ears = 0) - Customize back camera height: 20 units (custom_back_camera_y_size = 20) - Port corner radius on bottom side: 8...

thingiverse

My some other things: <img src="http://things.ruvim.info/img/Disc-Sander-Duo.-D50mm,-D75mm.jpg" alt="Disc Sander Duo. D50mm, D75mm" title="Disc Sander Duo. D50mm, D75mm"></a> <a...

thingiverse

### Installation Orient the base on the north-south axis using its two markers, the top of the wire facing north in the northern hemisphere or south in the southern hemisphere. ### Reading the time The reading is done by observing the shadow of...

thingiverse

Some of these items can probably be changed for cheaper or better alternatives, but these are the exact elements I used: Main Components + [Raspberry Pi 4 Model...

prusaprinters

Ideally, it won’t take me another 7 years to figure out how to count the hours- so if you have any ideas, please let me know in the comments! Thank you! -Ricky D. Building Instructions: NOTE: all tolerances are extremely close, so depending on your...

prusaprinters

Id basically be redesigning the duct part (Which would take a lot of time and I wouldn't feel comfortable unless I tested it myself, which would also take time) or poorly enlarging the slots, and I don't think that would look very good. Does this...

prusaprinters

You will also have to add to the OpenSCAD file the 'use ' command substituting the filename of the font for "fontname.ttf". The OpenSCAD "Help/Font List" menu item shows what fonts are available, so if it doesn't show up in the list then it is not...

thingiverse

So multi-axis is something that has had some next shiny object attention to it and now, how about multi-stroker capability. This is more a future thing for custom scripts, maybe custom software to control 2 handys simultaneously and catering for left...

prusaprinters

Check it out at https://www.thingiverse.com/thing:3677946.5/8/19Check out my new Triple Axis Tourbillon design at https://www.thingiverse.com/thing:3615577It's based on a Cabestan watch of of the same name.5/1/19Added a picture that shows the...

thingiverse

You may think your printer's X and Y axis are a perfect 90 degrees but have you ever actually tested and verified it over long distance? Two 30mm parts fitting together is a lot different than two parts ten times that size fitting together. I...