Front frame 3d models

222318 3d models found related to Front frame.

myminifactory

If you use the shortened fan ducts with V6 nozzles, check if some part of the hotend collides with the plastic frame of the buildplate clip on the centre back when doing a bed leveling during measurement of the contact point in the back. You might...

prusaprinters

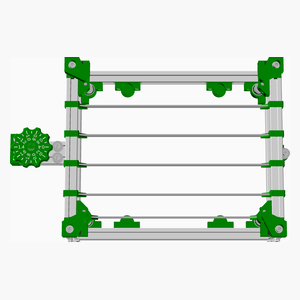

However, some differences: as I don't have a bottom on my frame, the motor is mounted on arms that mount to the 2020 at back. Motor position can be adjusted, so there's some leeway in choosing the belt length (I use 1220mm)</li> <li>the bottom parts...

thingiverse

Attach the top extrusions to the rest of the frame.  <span></span> [Top](#TOP) --- <a...

prusaprinters

Below is a list of modifications I applied to my machine: 3D Printer Tube Frame Stand You'll need this as a base for the plexiglass enclosure. The parts for this enclosure are uploaded with this Thing, so you can find them under Thing Files.</li>...

prusaprinters

After successfully getting as much Z height from my first MendelMax as I could with these carriages: MendelMax Vertical X Axis Carriages I promptly dismantled it and sold its frame to fund a self-built Prusa i3 clone. Long story short, a few months...

prusaprinters

Like - New-U EvolutionWhy build it?Using provided attachment bracket, lock did not fit anywhere around the frame. It probably works on most of the bikes but not on this specific one. Therefore putting it on a rack it seems like a quick access option...

thingiverse

... 13) Enlarge the filament bracket using a drill and 3mm bit 14) Mount the filament bracket to the top of the printer frame using the M3x10 screws and stepped nuts. 15) Put the filament roll on the bracket and feed the filament into the extruder.

prusaprinters

The photos show a frame from an IBM Selectric typewriter being bored to suit a larger mechanism, after careful concentric alignment to the existing hole. I used cutting fluid to start with but found it easier to spray a tiny squirt of WD40 on whilst...

prusaprinters

The sea frame pieces were rather large, and so in order to accomodate any smaller printers, they have each been split in half and labeled as parts “#A” and “#B”. These halves can be kept separate if desired, although my recommendation is that they be...

thingiverse

Used M5 screws and lockingnuts to Mount the entire axis to the frame. You need some rather long M3 screws for the Lead-screw nut. Hardest part: You do need to drill some new holes to Mount this. Might want to make the holes a tad larger to make room...

prusaprinters

The other 4x should be at least 12mm for mounting through an open-frame fan or at least 40mm for mounting through a 25mm fan. Similar Imperial and US Customary sizes will work too.</li></ul><p>All parts should be printable without supports. PLA is...

cults3d

I will try to help :) UPDATE 20 IX 2021 Version 1.1 with beveled holes in base and top parts (will help if your first layer is squished) and with very small ridges on bars and inside base and top (lanter will hold together stronger) New version of...

thingiverse

Final Note: I have been using the four-piece center frame design because of printer size restrictions I had at the time, for just under three years now. The only issues I’ve run into were with the wall mount layer separation mentioned below. Besides...

thingiverse

(Also contains STL files, as I'm mostly changing existing stuff...) **Design changes:** o changed X and Y Axis idler to a standard M3 GT2 belt idler pulley o added stops for the rods of X and Y axis, also ZMax clamps, so they dont move when not...

thingiverse

The Dry boxes fit the Creator Pro frame perfectly. I have this dry box sitting on top of an overturned box. <strong>***1/13/2021 Update***</strong> I'm not a fan of the single bar design any more. Changing out one roll can be cumbersome so I'm...

prusaprinters

The whole resulting clip should also come as a print-in-place solution.I designed a rail piece as base for the hinge so that it can be glued to the outside U-shaped frame of the box.Reused Projects[Ikea Samla box | 3D CAD Model Library | GrabCAD] for...

thingiverse

It is also lightweight and portable, can be disassembled fast, and takes up little space (thanks to the IKEA GUNDE chair used as a frame). Construction allows high precision with Hall effect sensors, smooth stick travel, and no backlash, thus...

prusaprinters

When printing the arm tensioner frame piece take care to add support blockers as shown in the screenshot, this should be done for any other part that otherwise requires support and has perpendicular inset holes in order to prevent Cura from...

thingiverse

\nGlue the screen piece to the center piece \nCut a soft material for the ski goggle face frame and glue it in place; I used foam or rubber sealing, which should work just fine. ... \nGlue the mask piece and center piece together \nAttach head...

thingiverse

Fastening them in such positions also takes quite less force – this allows us reach another point needed within frame itself once reaching right above said door since it houses important stuff - if that makes sense. I attached my mount to the...

thingiverse

Place the foil onto the telescope frame, looping the washers around the posts. Insert the mirror tower and adjust as needed. Use scissors to cut the sun shield into the desired shape. ...For best results, cut straight lines between adjacent washers...

thingiverse

I took the original idea, hooking the bracket onto the Da Vinci frame and made a few tweaks to improve its stability. I bolted the webcam directly onto the bracket and made sure the camera stopped drifting off-center. First, you can print the parts...

prusaprinters

... Watch out not to knock your clamps off the bed, I switched to low profile frame clips that don't use up as much space as the standard foldback clamps. You can print this with 0.6mm line width to save some time. Category: 3D Printer Accessories

thingiverse

Bottom bracket: This part slips on to the stock extruder frame with a nifty slot. The bottom wheel uses the SMALL axle/pin. Sand this wheel hole and its axle to get the wheel to spin easily when you flick it with your finger. To get the PLA through...

myminifactory

The Lapith's head and right arm, the Centaur's left foreleg, left hind foreleg, left arm and right hand and parts of the frame are missing. Plaster drapery possibly was added to the roughly worked patch of the background between the Lapith's raised...

prusaprinters

The Gamma Mods are designed to increase the overall reach of the OWI-535 Robotic Arm Edge by approximately 22.5 cm.Some of these parts require cutting part of the OWI-535 frame, which is a non reversible. Be certain you want to do these modifications...

thingiverse

Slide the assembled top part containing the pcb into the frame first, then slide it down and into the broad hole, the bottom part provides 9. Add a 12 Ohm resistor to the red LED's wire. Red is rated ~2.2V DC, Blue and Green ~3.3V DC each 10. VCC...

thingiverse

Update April 27, 2020 Added Version C8.1 with an optimized rubber band holder (Thanks to Corona-Hub-Vaihingen!) Update April 18, 2020 Added a stack of two frames (Thanks to Phillip Stinner!) This is a clear development from our first version of the...

thingiverse

Z axys mod Only attempt if you are confortable with drilling the frame and dissasembling of the printer as the whole gantry needs to be removed and dismantled. 1. With your wheels still attached measure the distance from the center of the wheel...

grabcad

The transformer and load assembly is mounted on a 3/16" thick carbon steel mounting platform and the load center/distribution assembly is mounted to the standard 2" x 2" x 1/8" square carbon steel tubing frame, resulting in an extremely stable,...