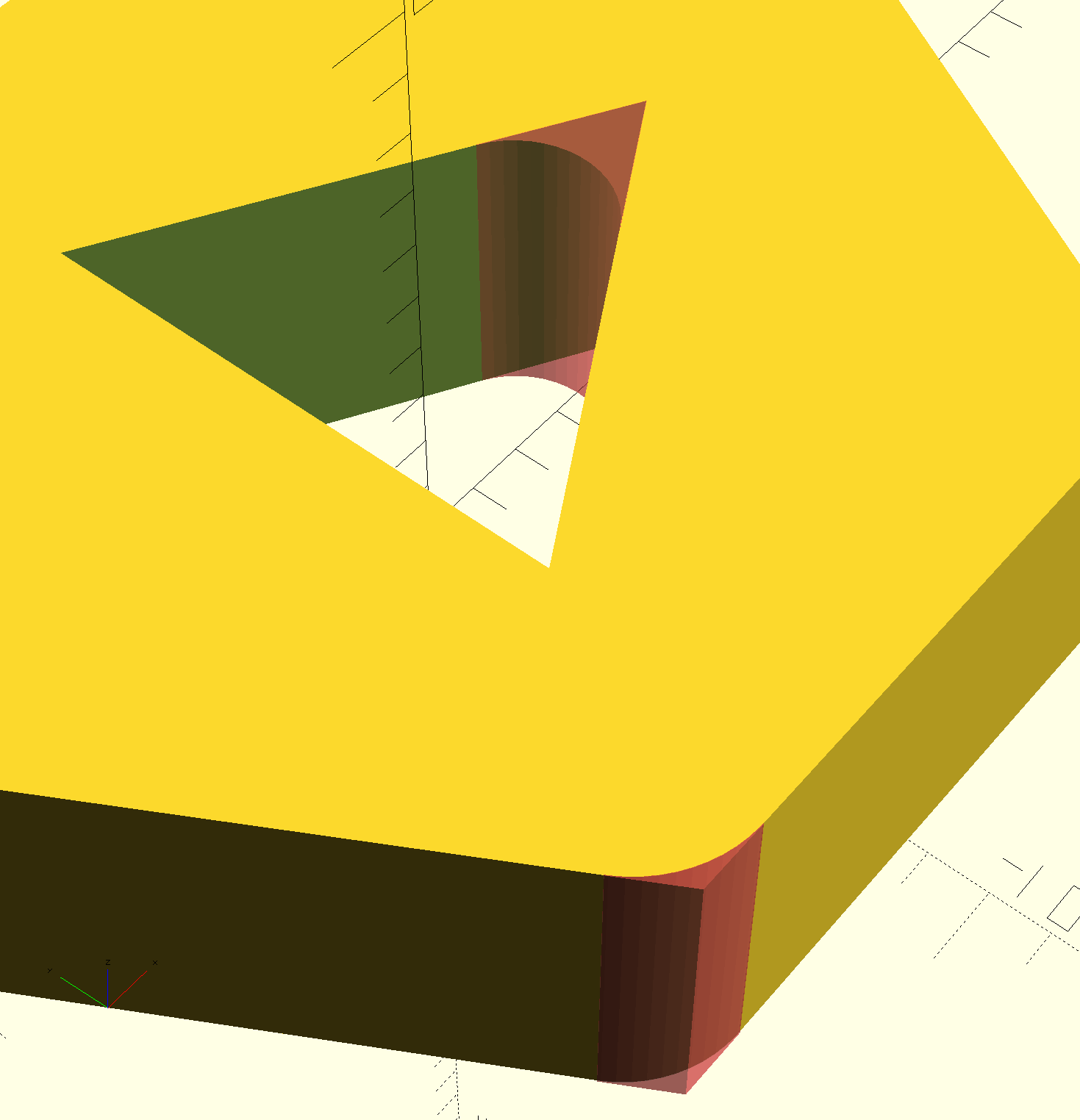

calibration square 3d models

87028 3d models found related to calibration square.

cults3d

Calibrate: (Watch This Video) Www.youtube.com/watch?v=3yIebnVjadm Profiles: all have been set to "magic number" heights (watch this video) www.youtube.com/watch?v=WikT8asT90A Speed Print Speed Is 45mm/s Retraction: 4.2mm @ 17mm/s Z-hop: Set To...

prusaprinters

If you have a calibre greater than .22, use the 8mm file. In addition, if you're worried about a pellet's path not being straight after printing, which is reasonable enough, use the 8mm file.</p><p>The hole in the inner tube is 8mm...

prusaprinters

Now it prints better for me.Hinges are a bit tighter by default (Works well for well calibrated printers)Thickness is a bit reduced by default.I added a few more logos to choose from. I added Beer and Gin logos, as requested by <a...

thingiverse

Installation and Calibration: Attach the device to your water meter. Turn on power for electrical components. Move the photo transistor sled with one screw until it directly points to the tip of the desired arrow. Move the LED so that the white...

thingiverse

After calibration I ended up at 425 steps/mm. 5. During your first test print, check the extruder stepper motor to ensure that it isn't either skipping (current too low) or overheating (current too high). - I'm using a 23 mm thick "pancake"...

prusaprinters

If this does not work then I will need to extend the housing and seporate the two mechanical functions.The encoder can be redesigned to either: Use reflective phototransistor rather than a break beam style phototransistor, this sholud make that...

thingiverse

It is by no means perfect, but should go together ok if you have a well calibrated 3D printer. Minimal to no sanding/filing/drilling out required. It features a single 5.25" bay and a single 3.5" bay, turbo display, turbo/reset buttons, keylock...

prusaprinters

If you don't want to damage your costume or stick a velcro square on it, you can use magnets and use the attached magnet backer. Magnets add significant weight to the badge, so keep that in mind and try not to jostle yourself around too hard on those...

prusaprinters

Work quickly though as it's easy to glue the meeting faces in exactly the wrong spot if the glue goes off too quickly.You don't need any special tools, but I use the square edge of the chopping board to check for square as I go along. The locating...

grabcad

The LED light head on this unit produces a brilliant flood pattern of light that is ideal for illuminating enclosed areas and hazardous locations where flammable vapors, gases and dusts may be present.This explosion proof LED light fixture is...

prusaprinters

In 1:1 (square) format, a lens that can cover that diagonal also should be able to cover a square with approximately the same diagonal, which would be 30.59x30.59mm. In infinity:1 (the limit on panoramic aspect ratio), <strong>a lens covering that...

thingiverse

+ Handle-lid with squares *and* snap-on brim to fit in the magnet holes more securely and *with* extended prongs to secure the Inner Mandhala. + More secure but doesn't fit inside gradient in current form. + Has arrows to indicate the...

prusaprinters

In 1:1 (square) format,a lens that can cover that diagonal also should be able to cover a square with approximately the same diagonal, which would be 30.59x30.59mm. In infinity:1 (the limit on panoramic aspect ratio),<strong>a lens covering that...

grabcad

A round-pole design makes the assembly easier to handle and transport compared to square-shaped models.A horizontal T-mount platform is provided at the top of the tower for mounting customer-provided equipment. The tripod features a rotatable head...

grabcad

A round-pole design makes the assembly easier to handle and transport compared to square-shaped models.A horizontal T-mount platform is provided at the top of the tower for mounting customer-provided equipment. The tripod features a rotatable head...

thingiverse

You can put bevels and buttresses on any edge; just make sure to specify the correct normals. ### Subdivisions You can set the number of...

thingiverse

With a slightly smaller drill bit, you must make sure your holes are plumb and square to the work piece, so a drill press is recommended. Some of the bolts will be able to accept a nut, but some others will be self-tapped into the hard cast...

prusaprinters

With all of that stuff in place, set the large 2x2 and 2x4 tiles into the center (for Change is Constant), then set the game board tiles down in the square created by the character tray lid storage boxes (check out Box-Layer3.jpg). I like to put my...

prusaprinters

You could also have multiple logos per long side if you want as well! For the brackets, I included the different colored squares as individual STL files to make doing the multiple extruder option with PrusaSlicer easy to implement. This means that...

prusaprinters

Look at the gcode. Parts needed You need an AC Infinity AIRTITAN T8-N...

prusaprinters

Look at the gcode. Parts needed You need an AC Infinity AIRTITAN T8-N...

prusaprinters

For a 0.2mm layer height, the pause will be at layer 4.00 (20). Assembly: Insert an M3nS square nut into each of the knife strip pieces you have for your configuration. Make sure each nut is fully seated in its pocket and aligns with the...

prusaprinters

Work quickly though as it's easy to glue the meeting faces in exactly the wrong spot if the glue goes off too quickly.You don't need any special tools, but I use the square edge of the chopping board to check for square as I go along. The locating...

thingiverse

After meticulously squaring the frame, the problem was resolved. **Mandatory disclaimer** ----------------------- I am uploading this a few weeks after I have mounted everything and tested that it works. However, the measurements are fine-tuned...

prusaprinters

I recommend assembling the two verticals and and top with the utmost care to ensure it's all square! Do to the quality of Creality parts, they may or may not be cut square on the ends. So using the joining plates, assemble so that the verticals are...

prusaprinters

You may use the square nuts at the bottom of the base parts for securing the acrylic panels too, however, they are meant for future modular attachments I plan to make. Components needed(BOM): -Alphacool front I/O-panel for servers...

thingiverse

Heute mal ein Video zum SpeedyBee Master 5 v2 Frame ich hoffe es gefällt euch😊Die verbauten Komponenten findet Ihr hier in der Beschreibung.Teileliste:Frame Kit SpeedyBee Master 5 v2:https://www.speedybee.com/speedybee-master-5-v2-frame/Empfohlener...

prusaprinters

Anyway, the improvement is extraordinary, the squares of the photo are printed with 1 single layer of skin and without filling. Translated by Google Print instructionsCategory: 3D Printer Parts Print Settings Printer Brand: BCN3D Printer: BCN3D+...

thingiverse

Drill holes in the aluminum and screw it into the magnetic tabs for a secure square hold. Once assembled, glue everything together using WELD-ON #3 Acrylic solvent cement, which dries in a few minutes to an hour and welds the parts together. This...

thingiverse

BOM - 5 x IKEA BETYDLIG Curtain Rod Holder (http://www.ikea.com/au/en/catalog/products/70219892/) - 8 x M3x10mm Cap Head Screw - 8 x M3 Square Nut - 1 x 1m PTFE Tube - 4 x Wall Screws - 1 x 1m M8 Threaded Rod - 16 x M8 Nut - 16 x 608 Bearing Printed...