makerbot slicer 3d models

72417 3d models found related to makerbot slicer.

cults3d

All model parts are prescaled to 28mm scale, and are internally consistent (i.e all parts will fit together without you having to adjust their size in a slicer program before printing. Hopefully the image gallery and above description should be...

grabcad

Soap slicer - an essential tool for simple, accurate division of soap bars. Streamline your soap-slicing routine with this easy-to-use cutting machine. Simplify your soap-cutting tasks with a dedicated device that guarantees clean cuts every time....

thingiverse

You can also try adjusting slicer settings to get a better fit. After you get the right bevel gear and left wheel assemblies complete you need to drill them out with an 1/8 inch drill so that the brass axle spins freely inside them. I used a...

thingiverse

Youre done :) Just print two (or more) arrows and glue the halves together. Note on the Arrows: Ive had the best results with a bit of slicer manipulation: I added a modifier to the tip of the arrows such that the tips are printed at 100% density...

prusaprinters

In this case rescale the rear transmission shaft in the slicer to add 4mm in one direction ( the length). This V2 uses my new differential and my new 16 to 1 gearbox. The steering is also direct from the servo but this time the servo is not upside...

prusaprinters

Updated battery tray (Unprinted) Radiator in front doesn't look great from my slicer, need comments on how to improve. maybe just reduce detail. I print at .3.. on this. Added Battery Lid (Unprinted) Not as easy to print as I would like and no mount...

prusaprinters

It has an optional feature to add a carry strap to it.MaterialsThe amount of material for my actual slicer settings is shown below. So basically, 2 kg of brown and 1 kg of silver and you should have some left over. Your actual results may...

prusaprinters

(On completion of final checks this note will be deleted!)28 April - Added BOTTOM-BRACE_125 to the Printed parts schedule.DIMENSIONSTop - 280 x 370mmFrame - 340 x 260 x 400mm high (13.5 x 10.5 x 19 inches)TOOLS REQUIRED3D PrinterSaw (if required to...

prusaprinters

Means when you insert batteries the battery pack wont work until you connected it once for a second to the charging cradle (activates the 2S protection circuit board) I am rocking 3500mAh hours batteries in it.I tried 3 different designs available...

prusaprinters

It also gives me 3 less models to update every time the slicer changes something. It is very tedious updating all my dragons :)NEW REMIX POSTEDCrystal Night Dragon -...

thingiverse

For a guide on how to stack parts in different slicers see 3D printing nerds stacking guides on Youtube. -Sterilisation procedures- You must follow Prusa sterilisation guidelines when packing protective equipment. Our standard procedure is as...

thingiverse

Mine are 25mm, for example, the Cross Country Performance kit uses 30mm thick spacers so you could modify the height in the Z-Axis in your slicer to potentially get 2.5" of lift from the tophat spacers alone. <b> Rear spring spacers only and front...

prusaprinters

You can also try adjusting slicer settings to get a better fit. After you get the right bevel gear and left wheel assemblies complete you need to drill them out with an 1/8 inch drill so that the brass axle spins freely inside them. I used a cordless...

thingiverse

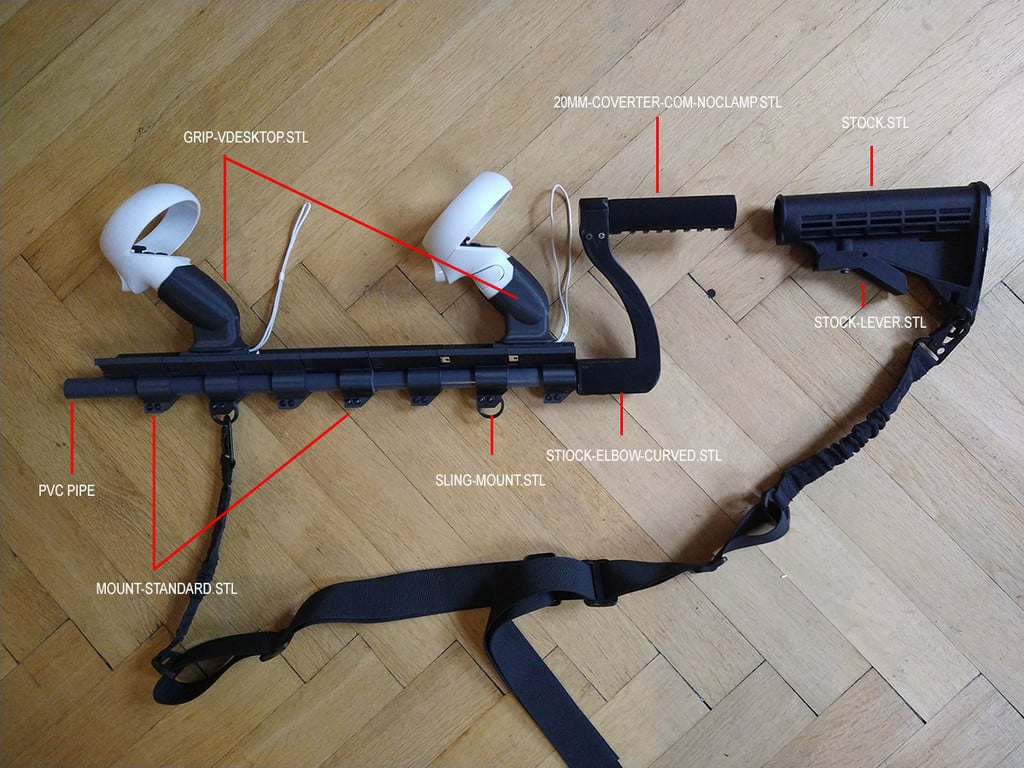

Printing parts • 20 % infill • Adaptive cubic infill • Supports when needed • 70% infill for some of the smaller parts All connectors are designed with zero tolerance, depending your printer and slicer there might be a need to sand them a bit in...

thingiverse

*Part 2: IMPLEMENTATION OF REFINED G-CODE MOVES* *ACTION:* -Generate G-code for desired part in Cura or similar slicer. -Delete the start script 'junk' to the line that reads 'G92 E0'. -At the top of the plain text G-code file write: ;...

prusaprinters

Mine are 25mm, for example, the Cross Country Performance kit uses 30mm thick spacers so you could modify the height in the Z-Axis in your slicer to potentially get 2.5" of lift from the tophat spacers alone. The lift given by the thickness of the...

thingiverse

2) "FILAMENT CHANGE DURING PRINT" AUTOMATION SCRIPTS (ONLY FOR CURA SLICER): Watch the videos: https://www.youtube.com/watch?v=UedAFRHJEBo https://www.youtube.com/watch?v=pQ0cZq7aNbU Below, G-Code scripts should be inserted into your slice by using...

prusaprinters

3 perimeters should be ok, but I recommend putting more walls around the screws using a modifier in the slicer, especially if you plan to skip on washers (seriously, just get some washers).It is highly recommended to pair the MMU with a filament...

thingiverse

If your printer allows you to print the entire deck, then you should do so, then you need to specify in the slicer an increased density of filling for the area bearing an increased load. If you have additional questions, I will answer them in the...

cults3d

All model parts are prescaled to 28mm scale, and are internally consistent (i.e all parts will fit together without you having to adjust their size in a slicer program before printing). Hopefully the image gallery and above description should be...

thingiverse

Then export in a format you desire.Raise3d's IdeaMaker software is also available for free at: https://www.raise3d.com/download/ideamaker-all-versions/ It is an excellent slicer but it has many useful features for manipulating .stl files, including...

thingiverse

##TLDR Instructions todo:  The following...

cults3d

All model parts are prescaled to 28mm scale, and are internally consistent (i.e all parts will fit together without you having to adjust their size in a slicer program before printing). Hopefully the image gallery and above description should be...

prusaprinters

If you consider this a problem, try to scale down the lamp base by 1-3% in X and Y directions (you can easily do this in the slicer). If you still have problems, then please visit the original thingieverse publication (<a...

thingiverse

Make appropriate adjustments in the printer firmware and slicer as needed for the change to direct drive. The new assembly will be heavier with the extruder on the gantry. Acceleration and speeds should be de-rated to compensate. ...

thingiverse

If required, you can adjust the height in your slicer. 20 Jan 2021: Update * Updated Dual Tensioner Rear Mount added - This has a flattened rear that allows the screws to be inserted from the rear for anyone wishing to use the rear mount/fan duct...

prusaprinters

The LED channels have a profile of 11mm x 3mm and are chamfered at the ends to allow easier threading of the LED strips through the channels. The STL files used for the revise LED guides: LED_guide_one_piece_style2 v6.stl I printed these pieces using...

prusaprinters

You can make your own picture with the help of this app from this site: http://www.thingiverse.com/apps/customizer/run? The front panel diagram is made in Solidworks. If you have a 0.2mm nozzle than I could recommend to use it for the best quaility....

prusaprinters

(On completion of final checks this note will be deleted!)28 April - Added BOTTOM-BRACE_125 to the Printed parts schedule.DIMENSIONSTop - 280 x 370mmFrame - 340 x 260 x 400mm high (13.5 x 10.5 x 19 inches)TOOLS REQUIRED3D PrinterSaw (if required to...

prusaprinters

No supports, no raft and using Stock .6 Nozzle settings on Prusa Slicer. The only files you need to print is the Main body and Turntable, everything else is included for ether reference so you can design your own using these style lamps or to check...