squid game face 3d models

439897 3d models found related to squid game face.

thingiverse

#### Print instructions for remixed parts can be found in originals: - PTFE Tube Cutting Guide_4.2_0.75: https://www.thingiverse.com/thing:2932635 - PTFE Tube Chamfer tool: https://www.thingiverse.com/thing:3121653 - Filament_4_to_1_adapter:...

prusaprinters

Note that on the side of the arm that faces the frame, there is an o-ring groove where you can press in a short piece of 1.75mm TPU filament. This is optional, but the rubbery TPU filament provides higher friction than plain PLA-on-PLA...

thingiverse

But there's always reasons like some special Texas Star facet or weird unique 100 facets faceting I guess, or perhaps some weird 100 face dice? But really, vanity, vanity, all is vanity? So without further ado, here it is in all its janky glory: ...

cults3d

Durant son court séjour dans ce camp, Travis dut faire face à ses idées préconçues sur les Sulibans et, en partageant avec eux, il réussit à les dépasser. (ENT: "Detained") Quand plusieurs membres de l'équipage, dont le capitaine Archer et le...

prusaprinters

So if you are masking the acrylic panels you have to make sure to keep track on which way they are facing.I started with gluing all the printed parts to the acrylic panel that would become the top of the case.Simply by adding a thin bead of silicone...

prusaprinters

Download version 1.5.4 or 1.5.6 of the RTCLib library on github (link can be found as a comment in the Arduino file of this project) since there is a bug in 1.5.5 for the time being.It all started with the simple conclusion that I was really annoyed...

thingiverse

It is only 180 mm deep which includes the front-facing feet which helps stabilize it. The frame is fairly wide at 280mm and sits 254mm tall. Although the parts are currently assembled separately, you will still likely need at a 300mm (or larger)...

thingiverse

Glue the four parts together with solvent glue (I used plumbers pipe fitting glue which welds as it contains acetone and other stuff which smells nice ;) ) There's none of that nice lettering that are on Flightsimmakers because I printed mine face...

prusaprinters

You will not need these as we will be using a different, high torque clock movement.Enlarge the central hole to 18mm. Slice off the original clock hanger so a fixing/blanking plate can be added later. Insert the large 6002 bearing into the...

prusaprinters

The construction costs are about 300€ and the construction time is about one day. contact email address ownplant@gmail.com Print instructions1.) Print out all parts and insert all thread inserts 33x "M4 Thread insert" they are all the same 2.) Saw...

prusaprinters

And have a wooden or plastic narrow tool to help you push the magnets in and keep them in place while the glue dries. Quick tip to make sure all magnets are oriented with the right polarity on a same face: your stock of magnets is basically a...

prusaprinters

It will be a bit of trial and error, but when it catches it should be pretty tight. This is designed so the face of the switch will be flush with the front of the part when everyting is seated correctly. ...Nothing should be loose and the M4 screws...

prusaprinters

As such, you may wish to solder the wires to the Arduino Nano, such that the Arduino Nano's LEDs will be facing downwards. Solder the 2.1mm jack socket wires to the Arduino Nano's GND and VIN terminals accordingly. Apply power via the 2.1mm jack...

thingiverse

Slide the SliderFrame onto the Barrels and push it all the way to the muzzle end, ensuring the orientation matches this picture. Figure 4: Place the InternalTriggerPin into the rectangular slot with the flat end facing outwards. Figure 5: Place the...

prusaprinters

To attach your Scanguage to the bracket, place the Scanguage face down. Remove the four screws on the back and save them in case your ever want to reverse the process. At this point the back can come off the Scanguage. Place the Scanguage bracket on...

cgtrader

(Red, Blue, Y Axis) Metallic Smoothness Albed- Normal R(G,A)\nPbr shading on this unity material utilizes both metallic/ roughness, ambient occulusion in channel\nPacked channel included here and available via unity materials with direct x and pbr...

thingiverse

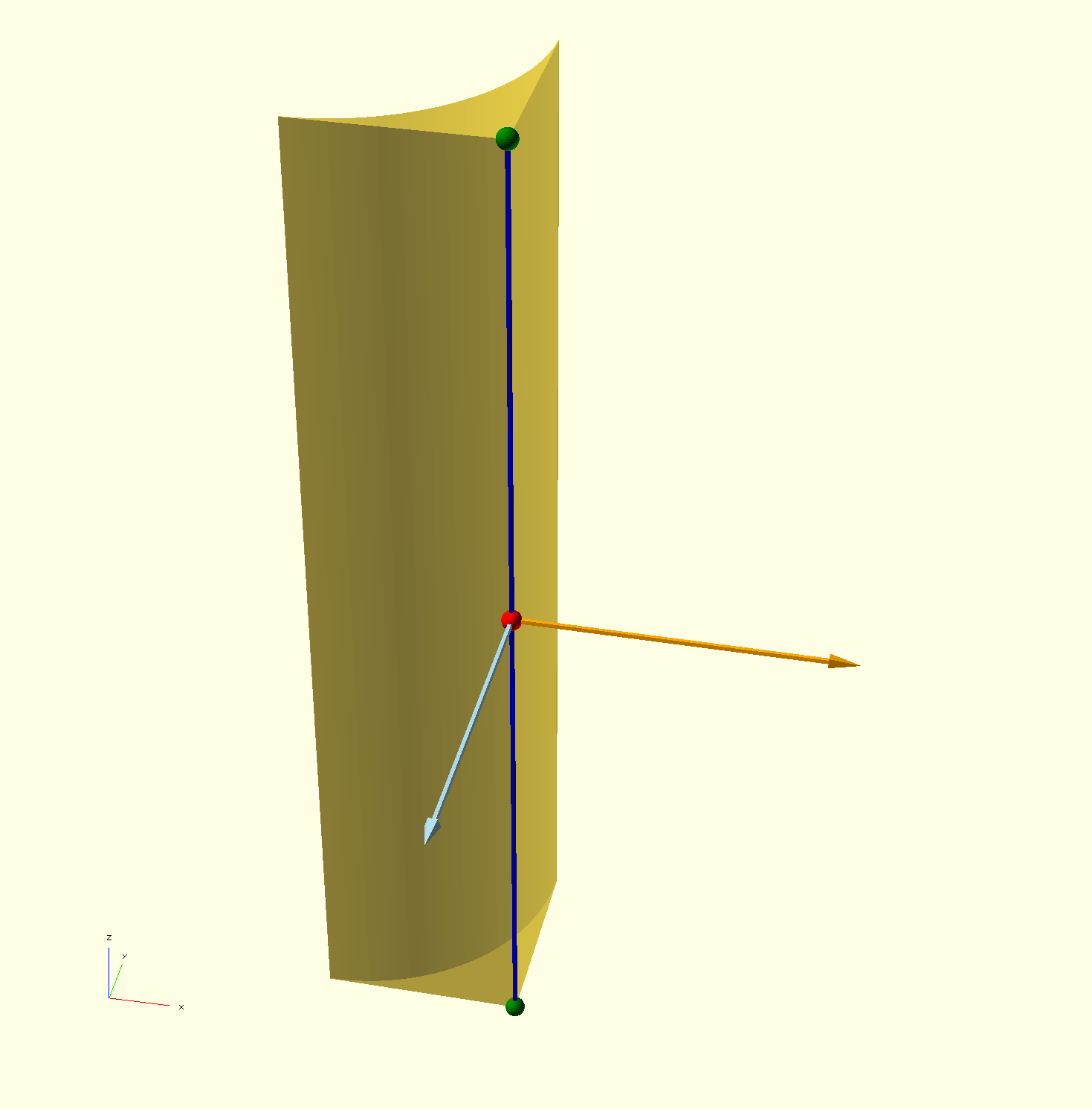

In the above image: - The blue line is the edge (corner) that you want to smooth, where the two faces meet. - The <span...

prusaprinters

Update 6/23/22Created a different lid (Lid v7.stl) and button (New_Button.stl) that is compatible the very nice TFT LCD display holder by design8studio...

prusaprinters

If you wish, it's also a good time to paint the bird logo as I did.The Budgie parts need to be assembled for use, but it's pretty simple:Put the E and M parts together with the sides that were on the bed facing each other. Push the top and bottom...

prusaprinters

Another reason I thought about using pencils was due to their properties of relative low mass and good strength as they are straight and show a low deformation while facing the forces on the proposed generator. Using pencils to interconnect also...

thingiverse

There is a T marked on the top of the clamp which should face up (i.e. Top) to ensure it grips the hotend groove mount correctly. 7. If the hotend is able to rotate, screw a M3x8mm or shorter screw through the hole in the hotend fan mount onto the...

thingiverse

Read this link for more information, and heed this warning.](https://e3d-online.zendesk.com/hc/en-us/articles/360014202318-Hemera-Bracket-Design-Guide) * Ensure that the ducts are at a good height and secure the fan duct by tightening the screws...

thingiverse

Insert your HEPPA filter & other media into the filter box- on a standard 86880 filter, the self-sealing gasket should be facing IN. </li> <li> Using the self-tapping screws, attach the filter cover. It may prove helpful to heat the screws...

thingiverse

Insert the BLTouch in the back of the shroud with the plug facing away from the extruder. 5. Insert the two 5015 fans at the top of the shroud. They kind of "pop" in if you line them up then twist them into place. I found putting tape on the...

prusaprinters

This means using a bolt of 35 mm (M4 or M3 will do) for the pivot.By the way, to access the Dremel chuck clamp you can…A) loosen the M3 corner screw on the upper_pillar_clamp and turn the Dremel roundB) take the rubber bands off and drop the...

prusaprinters

Remix improvements, continued (plus some print/assembly notes): To facilitate rotating the push block around (front to back) to easily switch between which thickness of side is facing your fence, the main handle provided has been redesigned —...

prusaprinters

(The last picture in the reel above is of the original desk, in which the 3D printed parts are Black PETG.)Building the DeskBill of Materials500g PETG Filament25mm Square Steel Tube 1.2mm Wall 2 x 150mm (Top a-frame...

prusaprinters

You'll probably need to tighten the screws incrementally or risk flexing the plate too much.Insert the BLTouch in the back of the shroud with the plug facing away from the extruder.Insert the two 5015 fans at the top of the shroud. They kind of "pop"...

prusaprinters

Tighten each pipe clamp.Insert your HEPPA filter & other media into the filter box- on a standard 86880 filter, the self-sealing gasket should be facing IN.Using the self-tapping screws, attach the filter cover. It may prove helpful to heat the...

prusaprinters

Here you can see how the connector has to be placed.The connector shown is not exactly the PRUSA's one because of its “wings” but don't worry, the component's design fits perfectly with the original one. ASSEMBLY INSTRUCTIONS Part 1:...