unity grass texture free 3d models

813080 3d models found related to unity grass texture free.

prusaprinters

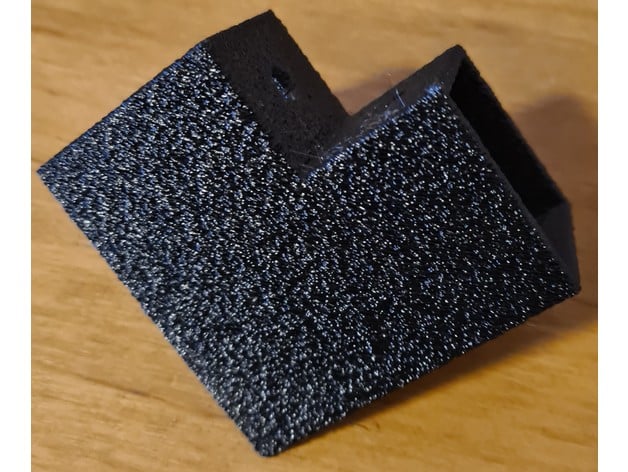

If you have one, I would highly recommend printing it on a textured PEI sheet without glue stick, which makes it very easy to remove the print without damage.If this helps you, please consider giving it a like, I would appreciate that a lot!Versions...

prusaprinters

Important note - After each panel you print check the holes with a screw again so you can compensate for it as you go. I printed on the glass side on my bed (not textured) so the print comes up glass like on the outside. Information about assembly:...

myminifactory

The overall size was optimized for efficient extrusion outlines (~.42mm), and to fit on a Prusa MK3 print bed (with a little finesse, two compartments can be printed at the same time.) The exterior faces can be customized with colors, textures, or...

prusaprinters

I airbrushed a few coats of Testor's opaque pink for the stripe, and then several gloss clear coats. After those, I sanded with 1200grit to remove some of the orange peel and texture, and then rubbing compound to remove the haze. I recommend also...

thingiverse

Print 1 of every part except the following: * canopy halves (outlined above) * I recommend printing it in right-left halves for ease of assembly and to keep the layer lines going the same direction for sheen/texture (assuming FDM printing) * 2x wing...

3docean

... marked a new beginning in the brand's legendary history while setting a fresh course for the American brand. Visit our website to see more of this model or any other additional services you might need. Tires texture not included in this set.

prusaprinters

I printed on the textured sheet by Prusa and didn't need any brim.Activate “detect thin walls” in PrusaSlicer and make sure that the thin verticals support layer is sliced correctly (see picture) ASSEMBLYDisassemble one KLAMBY. You only need the...

prusaprinters

Part 003 is the hands complete assembly, 004 is the lower arm, 004a-004k are all parts of the hand and parts 005 and 006 are the parts from which the lower arm is made (= assembled in 004) with the 'opening-mechanism' when entering the power armor....

thingiverse

It's best to print on a very smooth surface, such as glass or a smooth PEI sheet, rather than on a textured surface. The surface of the mask that prints in contact with the print bed will touch the negative, so any roughness could scratch your...

prusaprinters

Continue sanding using 100-200 grit sandpaper until you smooth out all the rough parts of the piece. Step 4: Body Filler At this point the body is at a fairly smooth and consistent texture. You may notice some small areas where the print may have...

prusaprinters

These buttons are much harder to find just by touch (if you have this need, you could remix the buttons with some texture on top to help with this), but they are plenty easy to press even though they are flush with the case. + The original button...

prusaprinters

... layers, 60° bed temperature, outside perimeters first. I turned the model 35° anticlockwise, then set the seam position to ‘rear’. The texture on the side panels comes from this textured bed plate, and I used the Tecbears black PLA.

grabcad

Designed to seamlessly integrate with trailers, this wheel offers hassle-free transportation of goods or equipment. The integrated hub enhances stability and performance, making it an indispensable component for your trailer setup.</s> /******/ This...

thingiverse

Performance is perhaps more dependent on exact horn placement (to the first layer line where the rotor is not pinched between the mouthpiece and horn and is free to spin. Another future test is to drop the 1mm cylinder holding the mouthpiece cone...

prusaprinters

Performance is perhaps more dependent on exact horn placement (to the first layer line where the rotor is not pinched between the mouthpiece and horn and is free to spin.Another future test is to drop the 1mm cylinder holding the mouthpiece cone that...

prusaprinters

I finally scrapped it and just redesigned the mount like I should have from the start, but technically this is a major revision hence it being Version 4. At any rate, I hope you enjoy the extruder, please feel free to ask me any questions or offer...

prusaprinters

My first print of the cup was also from PETG, so if you do not want to go fancy, just stick with PETG.I have printed all parts on the textured PEI powder-coated spring steel sheet (I really love this sheet and only use the smooth sheet for TPU and PC...

prusaprinters

I've found a value around 0.3 or 0.4 offers a good texture around the edge.Lid Style - The lid style of your cap can be toggled between 4 presets in the Fusion Parametric Bottle Cap file by navigating...

prusaprinters

Made this one for the wife sewing room from some color changing filament. Print instructionsgenerated by PrusaSlicer 2.1.1+ on 2020-01-07 at 12:29:45 UTC avoid_crossing_perimeters = 0 bed_custom_model = bed_custom_texture = bed_shape =...

prusaprinters

All the chess pieces will NOT require support during printing. 6/1/2023 - Added two hinge test print STL files. Print settings:All the tolerances of this project was design to be printed using 0.4mm nozzle at 0.2mm layer height. Layer height:...

prusaprinters

Print instructionsPrinting: All parts are printed on Prusa I3 MK3S, all the settings are in 3MF files except: Base, base top cover and base plug are printed on Textured PEI Powder-coated Sheet to achieve the best look; Shade is printed on Smooth PEI...

prusaprinters

You could flip over the “long outer middle no logo” bars and the “short ends” bars and use supports and then you would be fine if you are using a textured bed surface.The order in the print files i generated for the logo bars is 1: Red, 2: White, so...

prusaprinters

because I wanted to and I had a lot of fun doing it :-).I tried to achieve the following key features:Easy to print without support (no steep overhangs or long bridges and stuff).Top and bottom layer printable on print surface (so I could make good...

thingiverse

- It will flex a little bit, but not enough to wobble when fully assembled and printed correctly - It won't feel like higher end aluminium cases because it's plastic - You'll need to do a good job cleaning up all the orifices and vents before...

thingiverse

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

prusaprinters

(printer_notes=~/.PRINTER_VENDOR_PRUSA3D./ and printer_notes=~/.PRINTER_MODEL_MK(2.5|3)./ and single_extruder_multi_material) compatible_prints = "MK3S Plotter" compatible_prints_condition = cooling = 0 disable_fan_first_layers = 3 end_filament_gcode...

prusaprinters

PS: don't forget to round the tyre's edges while you are at it and you can refine the texture of the tyre with same fine sandpaper (the sanding rolls comes with maybe a too rough grain - probably 120). I have done few tests and the results have been...

prusaprinters

:).It will flex a little bit, but not enough to wobble when fully assembled and printed correctlyIt won't feel like higher end aluminium cases because it's plasticYou'll need to do a good job cleaning up all the orifices and vents before screwing...

cults3d

But at this point it you wouldn’t need, it unless that is the texture you are needing. OH!!! Almost forgot Material flow rate, now this will play a part in a couple areas. First it will affect your tolerance between parts, surface quality (all...

prusaprinters

The skirt and purge line must be removed before starting the print (filament color 2).Print all 32 pawns (file Pawns-U) using filament color 1.Print the tool (file Tool-U for magnet placing) using filament color 1.Warning 2: in case of having an...