anatomically correct 3d models

90031 3d models found related to anatomically correct.

prusaprinters

... in to both halves. Remember to dry your filament and set up your mini correctly! If you won't dry your filaments ahead of printing, the radiator holder's hex structures will become an absolute stringing nightmare. ...Don't say I did not warn you.

prusaprinters

It leaves enough time to set, so parts can be positioned correctly and it dries fast enough to hold awkward parts without the need for taping. I used the PLA version that comes in a tube. For both glues using a smaller amount is...

prusaprinters

The lamp stand, lamp shade and the bases of these two parts. The models in the STL files have the correct orientation. All parts are printed <strong>without support</strong> and with a layer height of <strong>0.2 mm.</strong><br/> Use an...

thingiverse

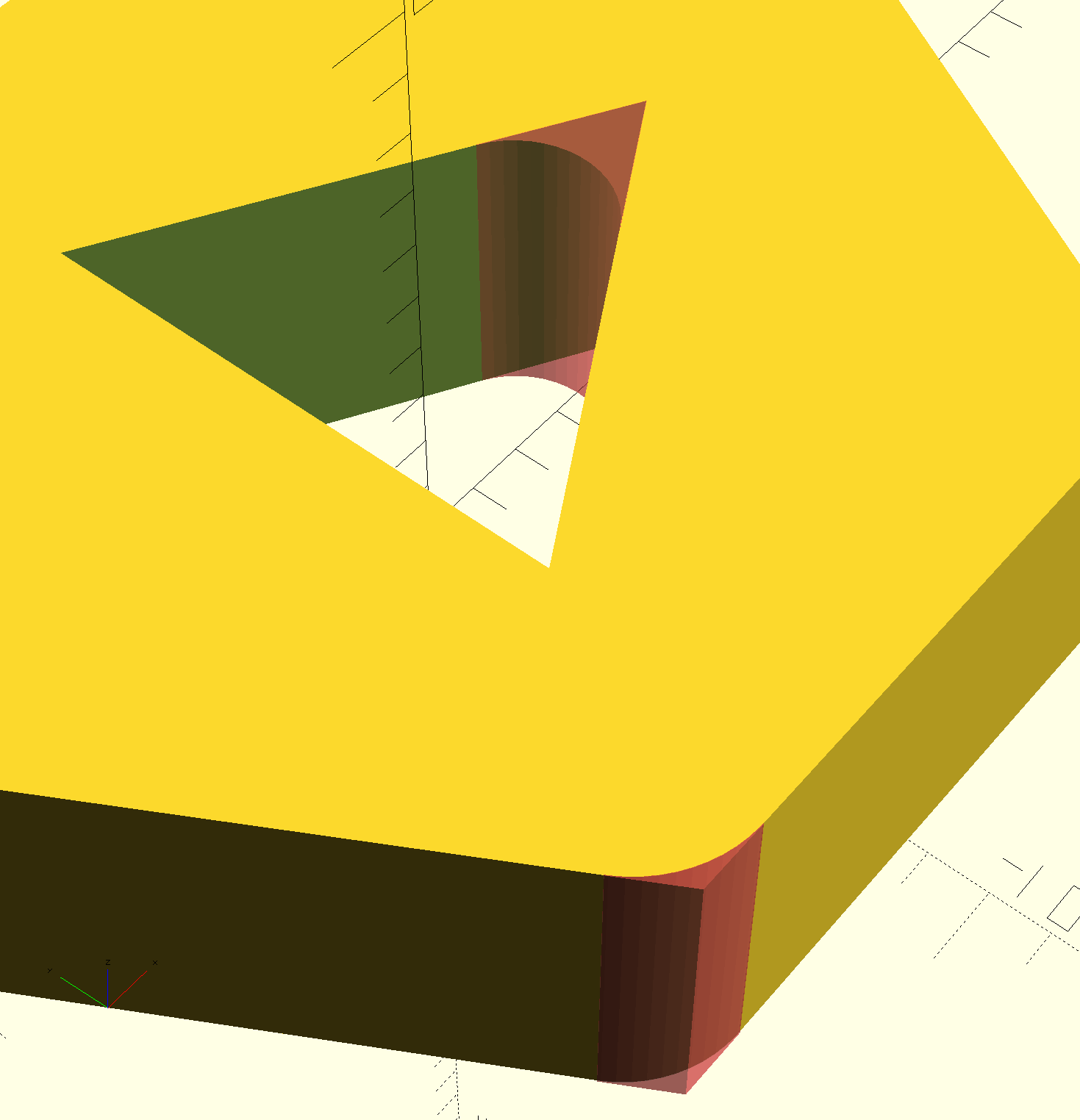

You can put bevels and buttresses on any edge; just make sure to specify the correct normals. ### Subdivisions You can set the number of...

gambody

The files have been checked and corrected in Netfabb and have been executed in Cura 15.06. The error-free files can be printed on all types of 3D printers.Flamethrower heavy tank size in assembly form is: 169mm depth, 250mm wide and 101mm tall. The...

prusaprinters

Mainly to avoid getting CA glue on the acrylic which can ruin the look, but also to have way more handling time.Have some straps and/or clamps ready to hold everything together.If you want to spend some extra time (and plenty of masking tape)...

thingiverse

It is not strictly necessary but make it easier for all the components to be correctly positioned. - *`AotWK_Extraboards`*: Insert to store player aids. If this part is printed it will be necessary print *`AotWK_CoinsBase`* or...

prusaprinters

I've included a test model which you can print to check accuracy.If you find the lid doesn't slide easily (printed too wide) or it doesn't really click into position (printed too narrow), check if your filament diameter or your extrusion multiplier...

thingiverse

(A photo of the donor device is the last in the list above and is also shown later in this document.)IMPORTANT NOTESince the Download all files link isn't working correctly Motion-sensing_USB_light_controller.zip can be downloaded instead. It...

prusaprinters

Mount it at the correct angle, extend the incoming ramp and the marble will successfully perform a looping.FunnelIt's a funnel.Auto-LauncherReleases one marble every couple of seconds. See it on <a href="https://youtu.be/TCUJiLz-vXs">YouTube</a>. It...

prusaprinters

I decided to alter the settings for the AxiDraw V3 XLX for my A1 machine (in inches because 'murica): x_travel_V3XLX = 25.75 y_travel_V3XLX= 34.33 NativeResFactor = 1016.0 # for 20t metal pulleys NativeResFactor = 850.2 # for 24t printed pulleys I...

prusaprinters

I corrected this with some adjustments in the Z motor mounts. While doing this I also added a variation of the Z motor mount for use with taller aftermarket motors.</p><p>UPDATE 08/22/2021: I made some changes to the two X axis ends. I have mine in...

thingiverse

After ensuring the gears turn correctly without the extruder connected, press the square end of the flex shaft into the sun gear. If you need to remove/disassemble the gearbox, it can be separated from the coupler to lift it off by applying...

prusaprinters

And for the large trestle you will need 10 Main Frames, 4 SideBraces + 2 CrossBraces, 12 Runners, 1 Bridge Top 10.5in 1, and 1 Bridge Top 10.5in 2. The SideBraces STL is made up of 5 CrossBraces STLs, laid out in the correct pattern for attaching to...

prusaprinters

... with 40% infill. Clamp printed at same settings but 100% infill. You don't need any supports if you orient things correctly (body with smaller hole on build plate, bushing with larger end on build plate, clamp with small spacer facing up).

thingiverse

I measured a SKR Pro v1.2 circuit card carefully and believe the board step file on BTT's github is correct and matches the actual circuit card mounting hole dimensions. I'm not sure if the SKR Pro v1.2 mounting hole positions changed over time...

prusaprinters

Push the magnet in place, making sure that you have the magnet in the correct polar orientation and that it did not flip and reverse sides during the process.FLOATING HEAD: With the face of the floating head facing down, exposing the magnet receiving...

prusaprinters

Some of my models will not look or work correctly with SFX-L or other variations of SFX standard.Build of Materials (BOM)3 x M3 Brass inserts (4-6 mm in length)3 x M3 screws length will depend on your brass insert and your computer case3 x UTS...

thingiverse

Take a coil with the sleeve correctly orientated in it and snap the front lip under the catch of each CoilSupport parts as shown in the labeled picture. It should snap into place and be a snug fit. Make sure the coil solder posts are facing the...

gambody

The files are checked and corrected in Netfabb and are flawless.The model consists of 45 parts, all optimized to be printed on any type of 3D printer. You can handle easily the Kodiak 3D model STL files in any slicing program, such as CURA 15.06 or...

prusaprinters

However in the first print these holes were too small and did not print correctly. You may want to adjust accordingly. Supplies Required: Beyond a 3d Printer and plastic for printing, the following is needed for installation: To attach the...

thingiverse

Corrected some inconsistencies between models. No need to print new ones, dimensions unchanged if you are happy with existing prints.2024-01-29 - Added new storage : GB/GBC Rumble carts. See description for more details.2024-01-24 - Added more...

thingiverse

Tape magnets into magnet holes, ensuring polarities are correct. Slot hinges into spacers, and test fit acrylic doors without gluing. Cut/Sand door corners as needed. You may or may not need to sand down either the top or bottom edge of the door...

prusaprinters

Red = correct screw alignment (This picture isn't updated for the new tensioner, the current tensioning arm should not have the hole for the nut).align the tensioning arm with the main tensioning block, and feed the 35mm M3 screw through its...

thingiverse

We found it useful to number our magnets by painting the bottom with liquid Wite-Out correction fluid then writing the number on them with a Sharpie after the paint dried. This helps to keep track of which magnet is which before inserting them or...

prusaprinters

I did a lot of work in fixing correct sizes for everything, but surely its not proven in all cases and every print setup may create its own displacements. For testing I designed Printer test presets that are simplest, least material consuming objects...

prusaprinters

:).It will flex a little bit, but not enough to wobble when fully assembled and printed correctlyIt won't feel like higher end aluminium cases because it's plasticYou'll need to do a good job cleaning up all the orifices and vents before screwing...

thingiverse

Transfer these into the Fusion File then the angles and distances should be calculated correctly.  In the component cross in the...

prusaprinters

Make sure to trim open (widen the hole) the top of both ptfe tubes with a blade to facilitate filament loading.Make sure to set your e-steps correctly via gcode for the BMG gear ratio:Standard 1.8 degree motor - M92 E830, M5000.9 degree motor - M350...

prusaprinters

I measured a SKR Pro v1.2 circuit card carefully and believe the board step file on BTT's github is correct and matches the actual circuit card mounting hole dimensions. I'm not sure if the SKR Pro v1.2 mounting hole positions changed over time but I...