ball clock 3d models

78460 3d models found related to ball clock.

prusaprinters

The aim of this project is to generate a low-budget, easily replicable 3D printer paste extruder developed from Reprap PRUSA i3 Steel for research projects in biocomposite production from local-food waste and 3D print food.The CAD file of the steel...

prusaprinters

The Ball Catcher I designed the Ball Catcher after testing the Black Ram Hand with the Simple Claw and finding that it was not enough to properly catch and hold a ball. I added side flanges to ensure that a ball could not escape once caught. This...

gambody

The 3D printing model's chosen scale is 1:32 for the FFF/FDM version and 1:64 for the DLP/SLA/SLS version.VERSIONS' SPECIFICATIONSFFF/FDM 1.0 version features:- Contains 166 parts;- A printed model is 408 mm tall, 394 mm wide, 510 mm deep;- REX’s...

thingiverse

Думаю такую вещи можно распечатать для своей девушки, жены тем самым показать что ваш 3Д принтер не стоит между вами, а наоборот помогает укрепить отношения :DFinished products - Готовые изделия: Creative Wall Mount Automatic Toothpaste Dispenser ...

prusaprinters

This will make the plant to concentrate the growth to the side branches and leafs.Do not overdose the nutrients, it will have an opposite effect.Use A+B component nutrient...

prusaprinters

As they take roughly four hours each to print on my machine, that works out to 13.5 days of round the clock printing. But you could print a few and make molds to cast them in something weather resistant (Great Stuff expanding foam, Silicone, etc.). I...

thingiverse

The engine backing goes in next with the open side facing backwards and holes for the engine nozzles at the 12, 4, and 8 o'clock positions. The engine decoration will index onto the small pegs and then the nozzles can go in. **Landing gear:** The...

prusaprinters

Install funnel into mid_upper housing and retain with 4x screws on the holes offset 45 degrees from the housing side ribs.Install fan on top of funnel with the corners clocked with the housing side ribs and retain with 4x screws via the fan's lower...

prusaprinters

Get some good sleep before you start, maybe start the print, wait for the first layer and then let it print the foundation layers and set your alarm clock to wake you up before the first filament change. From start to the first filament change you...

prusaprinters

As they take roughly four hours each to print on my machine, that works out to 13.5 days of round the clock printing. But you could print a few and make molds to cast them in something weather resistant (Great Stuff expanding foam, Silicone, etc.). I...

thingiverse

The DS1302 realtime clock is not necessary for this system, unless you want to write the date / time of issue on the NFC label. Firmware: starts with a menu system. Select one: (1) Read NFC card . Repeats reading and listing as long as new...

thingiverse

Small is fine - 1 GB is overkill|1| |DS3231 Real Time Clock Module|1| | CR2032 Battery|1| |Jumper wires, assorted|10-20| |USB Power Bank Battery 5V: optional; 9V battery adapter or other power supplies work as well|1| |16x2 LCD Display: Optional;...

prusaprinters

When disconnecting, the docking station put the notebook in low performance mode, slowing down to a clock speed of 800 MHz. Reconnecting does not reinstate full performance, and a reboot or hibernation process is required. On one occasion the...

prusaprinters

You can even try to play it with a chess clock, just to give some time pressure.Number of players23456Average game length (minutes)1225405580The Printing of HattoriAll the pieces are flat, which means they do not require supports. Have been tested,...

thingiverse

Inno-Maker said may have to make a change to clock speed but worked just fine for me. The reason for the PI ribbon header is to have the PI mounted inside the case and cut a slot in the bottom front or front and run it to the screen mounted in the...

thingiverse

However, assembling a ball and socket joint by pushing the ball into the socket is a logical fallacy. If the ball can be easily pushed into the socket, won't it just as easily fall out of the socket? My brave Bre the makernaut {8} has a ball and...

thingiverse

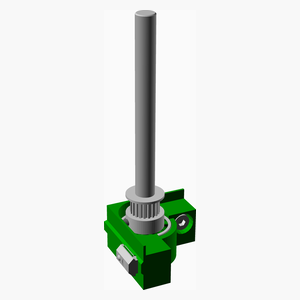

Put the pulley loosely onto the threaded rod and insert them into the ball bearingpulles.  ...

prusaprinters

Chronologie :10/08/2021 : Disponible à la vente en ligne (système entièrement monté et testé) :...

prusaprinters

This was improved by inserting a magnet into the selector pulling the steel ball away from the FINDA (see credits again).Devil 3 - an undervalued slicer settingThe above mentioned modifications immensely reduced the printing errors. All the “MMU...

thingiverse

- 17x M4x8 bolts - 17x M4 hammer nuts (no point in putting the squash balls in right now, because they'll just fall off) Step 6: Screw in the power terminal and press in the on/off switch in their corresponding places on the leg. You can use the...

prusaprinters

Fill the hollow bottom 3D printed part with the weights (2.5mm ball bearings in my case) up to the brim from the rear hole, and then fill it with resin. A little overflowing is fine. After that is cured, sand it flat.</p><p>Bond the top and bottom...

prusaprinters

old ATX) 1x Fan 12V (for the electronics case) 2x Nema 17 stepper motor 1x Nema 11 stepper with 100 mm integrated trapezoidal screw (see link above) Mechanics 2x 8 mm Rods, 370 mm (Y axis) 2x 8 mm Rods, 330 mm (X axis) 2x 4 mm Rods, 100 mm (Z axis)...

prusaprinters

It already exists a similar mod for the Bondtech version but I wanted it in the original one, hoping to give inspiration to the Prusa Team.This is not a perfect conversion because of the tight spaces I had to work with but after you set it up it...

gambody

Although he retired by the latter half of Dragon Ball Z, due to being largely outclassed by both his allies and their enemies, he is always present whenever a new threat approaches, and will occasionally lend a helping hand, thus proving himself to...

thingiverse

There is a clip to mount to the top of the heater, the Ball and Socket pieces (print however many you want) and then i modified the top where you mount the LED Strip to have more room for wires to run through it. I also modified the internal...

prusaprinters

https://www.aliexpress.com/item/32287187961.html)Solar panel case (print) and ball mount (print)175mm x 175mm glass protective cover for the solar panel (get from your local hardware store)UL2464 two core, 22AWG shielded wire (eg. You can freely...

prusaprinters

This is optional, but the rubbery TPU filament provides higher friction than plain PLA-on-PLA contact. The ball and cap parts print together as a single piece in the orientation provided. The ball sub-part has a built-in brim to keep it stable...

cults3d

Cookie mold set 108 things Angel X-82,20; Y-82,31; Z- 15,00 Arrow heart X-185,28; Y-113,33; Z- 15,00 Arrow heart2 X-185,28; Y-113,33; Z- 15,00 Bell X-69,80; Y-109,93; Z- 15,00 Chick X-82,22; Y-90,60; Z- 15,00 Cloud X-114,87; Y-72,61; Z- 15,00 Dog...

thingiverse

To mount them instead of the steel rods with linear ball-bearings, I used two pieces of 30x30x3 aluminium T-profile. Cut it to length, cut out space for the X-axis stepper, and mounted the linear rails on the profiles. The profiles themselves are...

thingiverse

It uses ball bearings with dimensions: 0.625" OD, 0.25" ID, 0.196" Wide. These ARE NOT 608 SKATEBOARD BEARINGS. They were just what I had lying around from a past project. You can just search for 1/4" x 5/8"x .196" Bearings on ebay or amazon and...